SEL-3350

The SEL-3350 is a versatile computing platform built to withstand harsh environments in utility and industrial applications. The SEL-3350 can be configured as a Real-Time Automation Controller (RTAC), a Blueframe application platform, or an industrial computer running a Microsoft Windows or Linux OS.

The SEL-3350 is a cost-effective rack- or panel-mount computing platform featuring an Intel Atom quad-core 1.6 GHz processor, available in 1U and 3U form factors. The SEL-3350 can be ordered from the factory with SEL RTAC, SEL Blueframe, Microsoft Windows 10 IoT Enterprise, or Microsoft Windows Server OSs preinstalled. Operating system conversion kits are also available for upgrading existing hardware. Additionally, SEL network and serial port drivers are available to support the installation of third-party Linux OSs.

By using error-correcting code (ECC) memory and eliminating all moving parts, such as rotating hard drives and fans, SEL computing platforms achieve one of the highest mean time between failures (MTBF) ratings in the industry. Designed, manufactured, and tested to the same standards as our protective relays, every SEL computing platform comes with our industry-leading ten-year warranty and is made in the U.S.A.

RTAC—Order the SEL-3350 as an RTAC for secure automation applications, such as a substation HMI or SCADA remote terminal unit (RTU) or for data concentration or event collection. For more information about the RTAC automation platform, its applications, and other available models, visit the RTAC platform page.

Blueframe—Improve your power system operational technology (OT) network management, simplify security patches, and ensure availability with the SEL Blueframe application platform. You can configure SEL computing platforms (SEL-3350, SEL-3355, and SEL-3360) with Blueframe to run specialized software applications, including the Data Management and Automation (DMA) and Distribution Management System (DMS) suites.

Engineering Workstation—Choose an SEL computing platform as your engineering workstation platform to get a reliable and robust system suitable for the harshest environments. You can view and change IED settings, view report and event data, and easily access diagram drawings and documents onsite. Securely and remotely access the engineering workstation using a VPN, Microsoft Windows Remote Desktop, or Secure Shell (SSH).

Information Processor: Data Concentrator/Protocol Converter—Seamlessly and flexibly concentrate data and convert protocols with any SEL computing platform and a wide range of data concentration and protocol conversion software.

Kiosk—Select the SEL-3350 for remote user applications that require the power of a dedicated high-performance computer. With the option of a small 1U formfactor, the SEL-3350 packs the computing power your application needs into a limited space. Passive cooling and a wide temperature range mean it is possible to install SEL computing platforms in locations where off-the-shelf computers will not survive. With one of the highest MTBF ratings in the industry, the SEL-3350 can operate with little or no maintenance, making it ideal for unattended operation.

HMI Visualization, Monitoring, and Control—Use the SEL-3350 to make a secure system visualization, monitoring, and control point for your substation or plant.

Features

-

- 1

LED lamp test button

- 2

Operational status, alarm, and HDD activity LED indicators

- 3

Ethernet port link status and network LEDs

- 4

Serial port transmit and receive LEDs

- 5

Four programmable bicolor LEDs

- 6

Front heat sink

- 7

Front Gigabit Ethernet port

- 8

Two front-panel USB 3.1 ports

- 9

Card insert for label

123456789

-

-

- 1

DisplayPort monitor connection

- 2

Four USB 2.0 ports

- 3

16 built-in RJ45 EIA-232/422/485 ports

- 4

Four high-speed Gigabit Ethernet ports that can be configured as four RJ45 ports, two RJ45 and two small form-factor pluggable (SFP) ports, or four SFP ports.

- 5

Configurable digital/analog input

- 6

Form C alarm contact output

- 7

Built-in power supply connections

1234567.jpg?n=63862969916000)

-

-

- 1

LED lamp test button

- 2

Operational status, alarm, and HDD activity LED indicators

- 3

Ethernet port link status and network LEDs

- 4

Serial port and digital I/O status LEDs

- 5

Four programmable bicolor LEDs

- 6

Front heat sink

- 7

Card insert for label

- 8

Front Gigabit Ethernet port

- 9

Two front-panel USB 3.1 ports

123456789

-

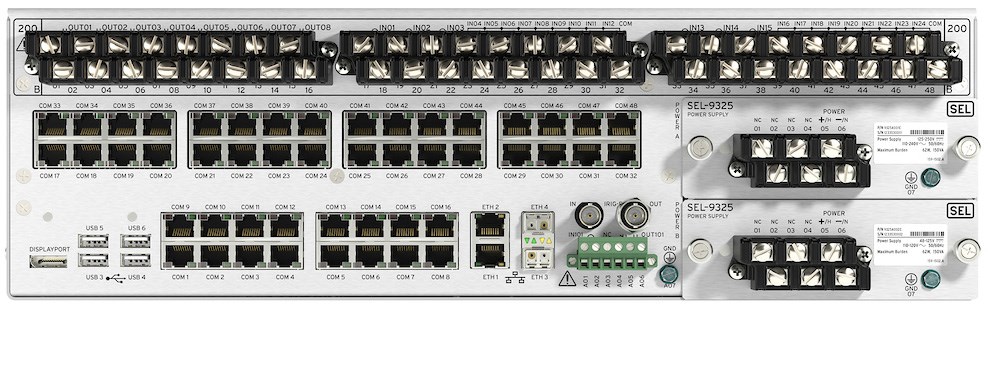

-

- 1

8 Form A digital outputs

- 2

24 software-selectable digital inputs

- 3

DisplayPort monitor connection

- 4

Four USB 2.0 ports

- 5

Up to 48 RJ45 EIA-232/422/485 ports

- 6

Four high-speed Gigabit Ethernet ports that can be configured as RJ45 or SFP ports

- 7

Configurable digital/analog input

- 8

Form C alarm contact output

- 9

Redundant hot-swappable power supplies

123456789

-

Details

Versatility

The SEL-3350 is a versatile computing platform that can be deployed as an RTAC, a Blueframe application platform, or an industrial computer running a Microsoft Windows or Linux OS.

For more information about the RTAC automation platform, its applications, and other available models, visit the RTAC platform page.

For more information about the Blueframe application platform and its available software applications, visit the Blueframe platform page.

The SEL-3350 can be converted between Windows, RTAC, and Blueframe OSs, offering the flexibility to upgrade existing hardware. For more information about OS conversion kits, contact your local sales or customer service representative.

Reliability

SEL designs, manufactures, and tests every computing platform in-house to ensure maximum reliability. There are no fans or moving parts in the SEL-3350, and it has a durable SEL power supply, passive thermal management system, error-correcting code (ECC) memory, and single-level cell (SLC) SSDs to provide reliable operation in the harshest environments.

We designed the SEL-3350 to withstand 15 kV electrostatic discharge, fast transients, conducted and radiated emissions, up to 15 g shock, seismic and sustained vibration, voltage surge, and large magnetic field disturbances. It meets IEEE 1613, IEEE C37.90, IEC 61850-3, and IEC 60255 protective relay standards. The SEL-3350 also meets IEC 61000-6-2 and IEC 61000-6-4 industrial environment standards. Our computing platforms have one of the highest MTBF ratings in the industry, and they are backed by a ten-year warranty.

For added protection, you can order the SEL-3350 with conformal coating to protect against harsh environments and airborne contaminants, such as hydrogen sulfide, chlorine, salt, and moisture.

Availability

Designed to keep your system operational for longer periods, the SEL-3350 includes a two-slot 2.5" SATA drive bay that can be loaded with solid-state drives (SSDs). The unique SEL Microsoft Windows Management Infrastructure (MI)/Windows Management Instrumentation (WMI) interface and configurable alarm service, Backup and Recovery Tool (BaRT), and watchdog timer maximize system availability by alerting users of potential issues and minimizing downtime.

Serviceability

Users can perform diagnostics, change out drives (SSDs) and power supplies, and install software and operating systems. Additionally, SEL System Monitor (SysMon) logs events specific to the installed system to aid in quick recovery.

Minimum Software Version

Video Playlists

RTAC Firmware Release Highlights

- RTAC R153 Firmware Update

- RTAC R152 Firmware Update

- SEL RTAC R151 Firmware: New Features and Enhancements

Digital Fault Recorder

- How To Configure Continuous Recording on the RTAC

- How To Configure SEL DFR Solutions

Latest Firmware Versions

There are no firmware versions available for this product.

| Product | Revision | Firmware ID | Date Available | Serial Number |

|---|---|---|---|---|

| SEL-3350 RTAC | R153-V0 | SEL-3350-R153-V0-Z000058-D20240918 | 9/25/24 | ~1242690001 |

| SEL-3350 RTAC | R152-V2 | SEL-3350-R152-V2-Z000294-D20240918 | 9/25/24 | ~1242690001 |

| SEL-3350 RTAC | R151-V6 | SEL-3350-R151-V6-Z000267-D20240918 | 9/25/24 | ~1242690001 |

| SEL-3350 RTAC | R150-V8 | SEL-3350-R150-V8-Z000303-D20240918 | 9/25/24 | ~1242690001 |

The Firmware IDs for older versions of the firmware can typically be found in Appendix A of the instruction manual.

Minimum Software Version

Instruction Manuals

Sales Resource Central access is required to view the content in this tab.

Sales Resource Central3350 - Software Tab

Configuration Software

Drivers, Firmware, and System Software

SEL offers a wide range of drivers, firmware, and system software for the SEL-3350, SEL-3355, and SEL-3360 computing platforms and SEL-3390 expansion cards.

Visit the SEL Software Downloads page to find available downloads for SEL computing platforms and expansion cards.

SEL-5815 PRP Driver for Windows

SEL-5815 adds Parallel Redundancy Protocol (PRP) support compliant with IEC 62439-3 to SEL computing platforms.

Learn more and download on the SEL-5815 product page.

SEL Backup and Recovery Tool (BaRT)

Use SEL BaRT to quickly and easily create a snapshot of your computing platform’s operating system and configuration. SEL BaRT was designed specifically for SEL’s computing platform line and takes advantage of each platform’s features.

Learn more and download here.

acSELerator RTAC SEL-5033 Software

acSELerator RTAC is an intuitive, easy-to-use application designed to configure the SEL Real-Time Automation Controller (RTAC) family of products, including the SEL-2240 Axion. The software offers a wide range of optional tools, add-ons, and library extensions.

Learn more and download on the acSELerator RTAC software page..

RTAC Libraries and Extensions

A wide range of IEC 61131-based libraries and extensions are available for the RTAC platform. Instructions for libraries and extensions are available in the Programming Reference and via the acSELerator RTAC help menu.

Learn about the available libraries and extensions on the RTAC platform page.

acSELerator Diagram Builder SEL-5035 Software

Diagram Builder is an application that allows users to create and manage visualization projects for the optional web-based HMI designed for SEL Real-Time Automation Controllers (RTACs).

Learn more and download on the Diagram Builder software page.

acSELerator Architect SEL-5032 Software

Architect allows users to configure and document IEC 61850 systems that include GOOSE, Sampled Values (SV), or Manufacturing Message Specification (MMS) communications. Architect automatically compares SCL files with IEC 61850 requirements to ensure standard compliance.

Learn more and download on the Architect software page.

Automated Data Collection

SEL Data Management and Automation (DMA) Application Suite

Available on the Blueframe platform, DMA applications automatically collect, store, and manage device-specific information like oscillography, Sequence of Events (SOE) data, device settings, and property information. They also provide automated password rotation and streamlined device audits.

Learn more on the DMA software page.

Visualization & Analysis

SEL-5601-2 synchroWAVe Event SOFTWARE

synchroWAVe Event helps engineers diagnose the cause of power system disturbances, including faults. It is a powerful and easy-to-use solution for displaying and analyzing SEL event reports and COMTRADE files.

Learn more and download on the synchroWAVe Event software page.

| Cable Part Number | Termination | Length | Notes | Schematic |

|---|---|---|---|---|

| C605A | DB-9 Male | 1 to 100 ft | SEL RJ45 Serial Cable (RS-232, DTE-DTE, RJ-45 M/DB-9 M, IRIG-B, Hardware Flow Control) | View |

| C489 | DB-9 Male | 1 to 100 ft | SEL RJ45 Serial Cable to SEL DNP (RS-232, DTE-DTE, RJ45 M/DB-9 M, IRIG-B) | View |

| C478A** | DB-9 Female | 1 to 6 ft | SEL RJ45 Serial Adapter Cable (RS-232, DTE-DCE, RJ45 M/DB-9 F, IRIG-B, Pin 1 Power, Hardware Flow Control) | View |

| C478N** | DB-9 Female + BNC | 1 to 6 ft | SEL RJ45 Serial Adapter Cable (RS-232, DTE-DCE, RJ45 M/DB-9 F/BNC F, IRIG-B, Pin 1 Power, Hardware Flow Control) | View |

| C605 | DB-9 Male | 1 to 6 ft | SEL RJ45 Serial Cable (RS-232, DTE-DTE, RJ45 M/DB-9 M, IRIG-B, Pin 1 Power, Hardware Flow Control) | View |

| C605R* | DB-9 Male | 1 to 100 ft | SEL RJ45 Serial Cable (RS-232, DTE-DTE, RJ45 M/DB-9 M, IRIG-B, Hardware Flow Control) | View |

| C477 | DB-9 Male | 1 to 150 ft | SEL RJ45 Serial Cable to GE DNP I/O (RS-485, RJ45 M/DB-9 M) | View |

| C607 | Tinned Wires | 1 to 330 ft | SEL RJ45 Serial Cable for Terminal Server (RJ45 M/Tin Wires) | View |

| C616 | DB-9 Male | 1 to 100 ft | SEL RJ45 Serial Cable (RS-232, DTE-DCE, RJ45 M/DB-9 M, IRIG-B, Pin 1 Power, Hardware Flow Control) | View |

| C629A | RJ45 | 1 to 100 ft | SEL RJ45 Serial Cable (RS-232, DTE-DTE, RJ45 M/RJ-45 M, IRIG-B) | View |

| C629R* | RJ45 | 1 to 100 ft | SEL RJ45 Serial Cable (RS-232, DTE-DTE, RJ45 M/RJ-45 M, IRIG-B, Hardware Flow Control) | View |

| C659 | DB-9 Male + BNC | 1 to 100 ft | SEL RJ45 Serial Cable (RS-232, DTE-DTE, RJ45 M/DB-9 M/BNC M, IRIG-B, Pin 1 Power, Hardware Flow Control) | View |

| C972 | BNC | 1 to 130 ft | SEL RJ45 Serial Cable (Modulated IRIG, RJ45 M/BNC M) | View |

| C429 | RJ45 Male | 1 to 100 ft | SEL RJ45 Serial Cable (RS-232, DTE-DTE, RJ45/DB-9 M) | View |

| C432 | RJ45 | 1 to 100 ft | SEL RJ45 Serial Cable (RS-232, DTE-DTE, RJ45/RJ45 M, Hardware Flow Control) | View |

*This cable is double-shielded (contains both foil and braid shields) with the shield connected to the shell at both ends of the cable for improved immunity to electrical disturbances that can cause data loss.

**These cables are for connecting to existing SEL serial cables with a DB-9 connector and fiber-optic SEL-2800 series transceivers.

.jpg?n=63846481698000)