SEL-849

Motor Management Relay

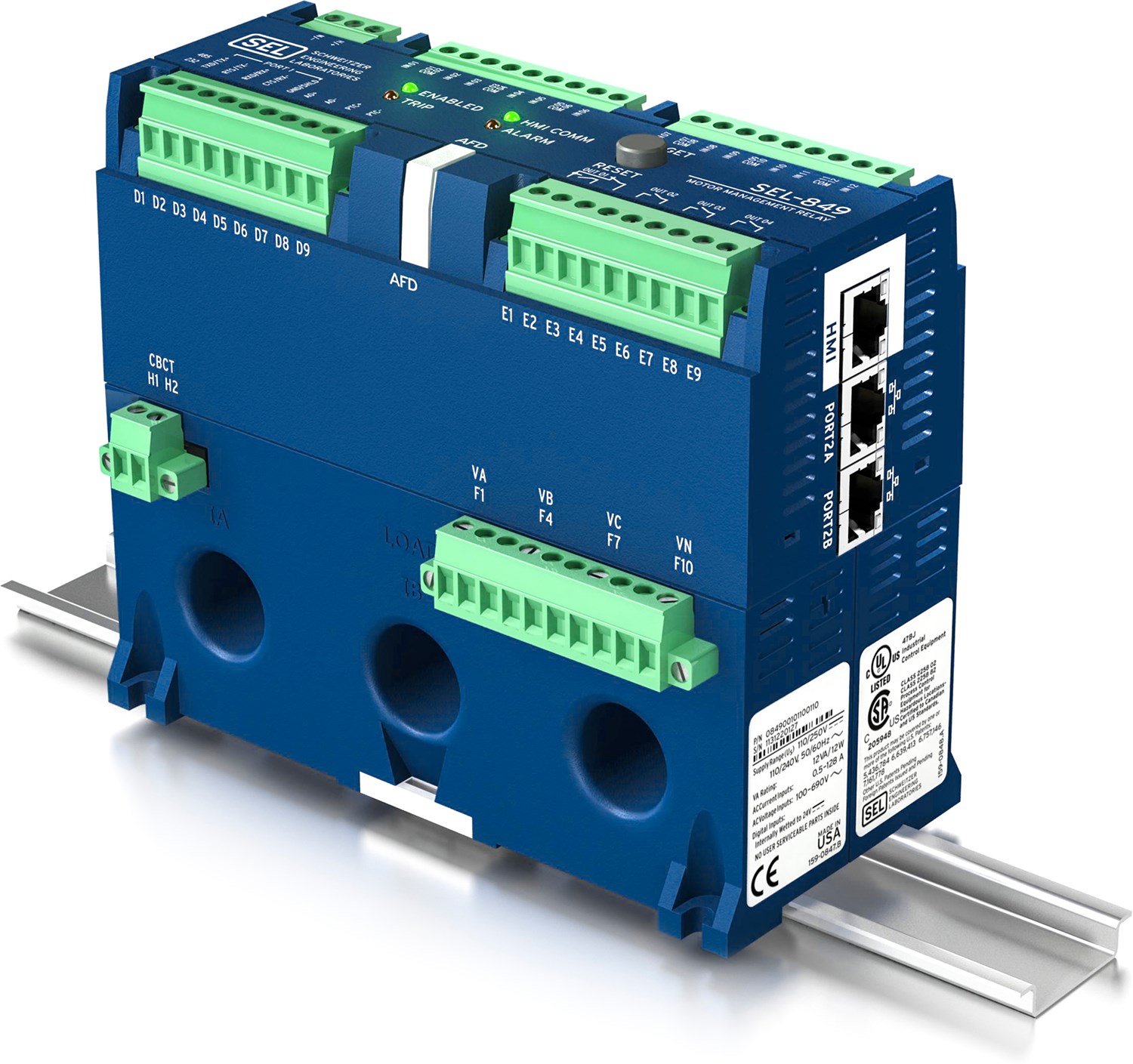

The SEL-849 is a versatile product suited for both industrial and utility applications. It offers current-, voltage-, and thermal-based motor protection; current- and voltage-based feeder protection; arc-flash detection; and power metering.

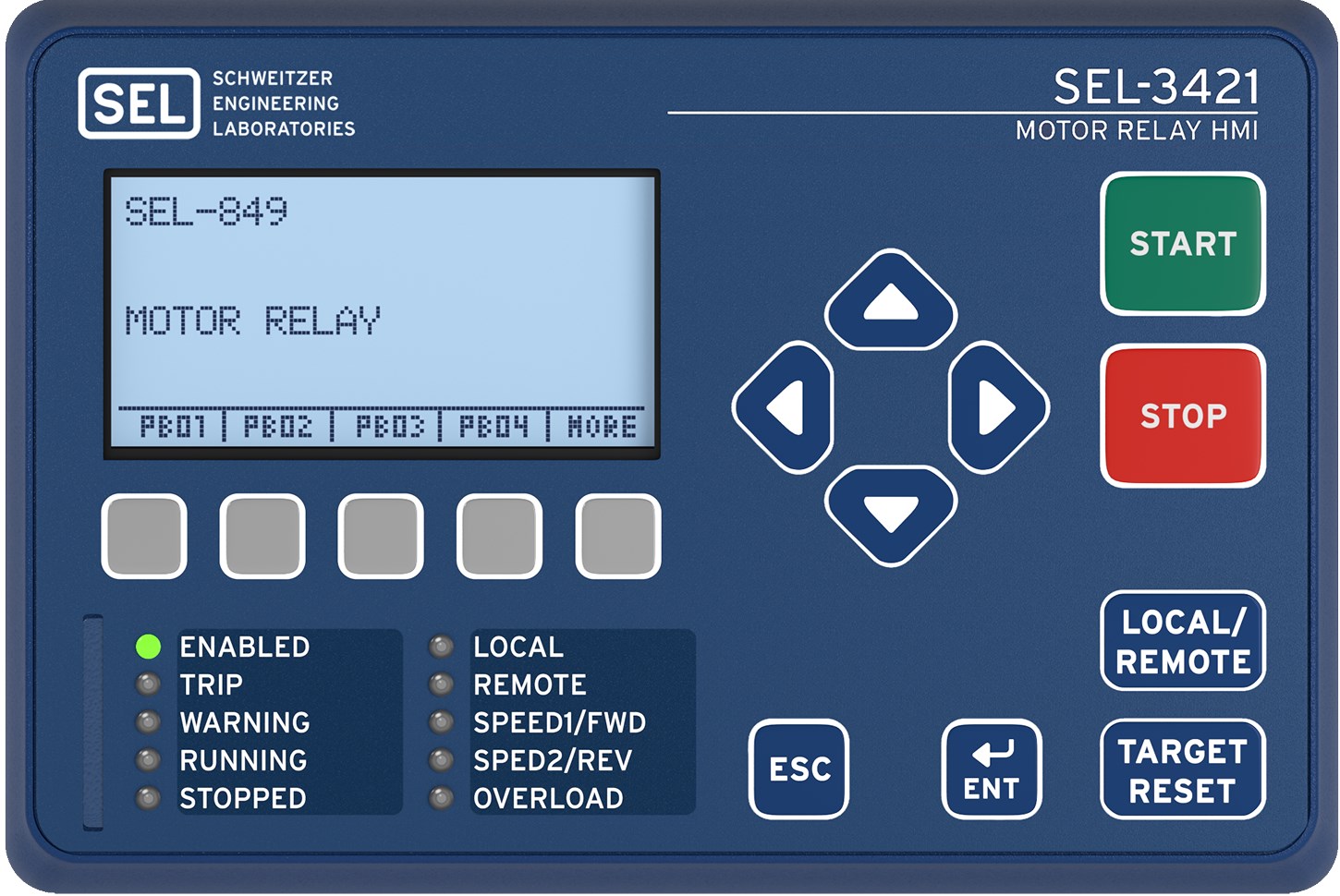

The SEL-849 installs easily inside a motor control center (MCC) bucket or a control panel. The optional SEL-3421 and SEL-3422 Motor Relay HMIs allow for simple remote communications.

Starting At

$1,000Motor Protection—The SEL-849 provides all basic motor protection features, including protection for short-circuit, load loss, load jam, frequent-starting, unbalanced current, and phase reversal conditions. Protect low- or medium-voltage three-phase induction and variable-frequency drive (VFD)-fed motors with an enhanced thermal model. Connect an external core-balanced current transformer (CBCT) to obtain sensitive ground-fault detection in high-impedance grounded systems.

Feeder Protection—Configure flexible instantaneous and time overcurrent elements (e.g., overcurrent, voltage, directional power) to protect low-voltage feeder circuits.

Second- and Fifth-Harmonic Blocking Logic—When multiple transformers are energized concurrently, it can be difficult for relays to distinguish between the magnetizing inrush current and fault current. Second- and fifth-harmonic blocking logic provides the capability to recognize inrush current and block overcurrent element operation.

Metering and Monitoring—Analyze SER reports and oscillographic event reports for rapid commissioning, testing, and post-fault diagnostics. Reduce separately mounted metering/monitoring devices by taking advantage of the SEL-849 relay’s motor start report, motor start trending, motor operating statistics, energy metering, minimum/maximum metering, and demand metering features.

Arc-Flash Mitigation—Improve worker safety using the relay’s built-in arc-flash detection (AFD). The AFD, supervised by overcurrent elements, delivers secure, reliable, and fast-acting arc-flash protection.

Direct Connection—Connect up to 690 V to the optional voltage inputs and up to 256 FLA (full-load amperes) through the built-in CT primary circuits. Use external instrument transformers for higher voltages or currents.

Optional HMIs—Install SEL-849 relays in MCC buckets, and connect the optional display modules outside the MCC for secure and safe relay access. Choose the HMI module that meets your needs: the SEL-3421 Motor Relay HMI (With LCD) or the SEL-3422 Motor Relay HMI (Without LCD).

Integration—Select from a variety of communications ports and protocols—IEC 61850 Edition 1, Modbus TCP/IP, Modbus RTU, EtherNet/IP, the IEC 62439 Parallel Redundancy Protocol (PRP), DNP3, SEL ASCII, and SNTP—to integrate SEL-849 relays into supervisory or coordinated protection and control systems.

Easier Testing, Commissioning, and Maintenance—The SEL-3421 allows you to perform key maintenance and operational tasks without plugging in a computer. The ability to view and set the IP and router address directly from the HMI screen makes relay installation easier. The HMI navigation keys can be programmed as pushbuttons to perform functions such as triggering reports or resetting values, making commissioning, maintenance, and day-to-day operation easier.

Features

-

- 1

EIA-232 or EIA-485 provides quick and easy engineering access.

- 2

Optical sensor supports high-speed, secure arc-flash detection.

- 3

You can use space-saving portals for motor conductors with a full-load ampere (FLA) rating range of 0.5–256 A or external CTs for an FLA rating of up to 6,000 A.

- 4

Optional direct-connect voltage inputs (allowing up to 690 Vac) enable voltage-based protection elements.

- 5

HMI powered Ethernet port lets you review status and event records externally to improve safety

- 6

A wide variety of communications protocols and media provide flexibility to communicate with other devices and control systems.

- 7

Power supply options include 110–240 Vac, 125–250 Vdc; or 24–48 Vdc.

- 8

Connectors for the thermistor input and AO let you monitor the equipment temperature and integrate with a distributed control system (DCS).

- 9

Connectors for DIs and DOs provide a convenient way to issue control signals and monitor equipment.

123456789

-

-

- 1

Large LCD display for navigation, relay control, and diagnostics

- 2

Context-adjusted navigation keys can be programmed to function as pushbuttons.

- 3

Two fixed and eight programmable tricolored LEDs

- 4

Fundamental motor controls

1234

-

-

- 1

Simple HMI for status and control

- 2

Configurable label for programmable LEDs

12

-

Details

Multiple Applications

The SEL-849 offers low-voltage motor protection in virtually all applications, including pumping, air-based, chiller, and bulk-material applications. It can be configured as a motor, variable-frequency drive (VFD) motor, or feeder protection relay. It can also be used as a telemetry device for monitoring, metering, and control.

Compact Design for MCCs

A primary application for the SEL-849 is for overload and arc-flash protection of MCCs. In this application, the SEL-849 operates the contactor, controlling the start and stop of the motor. The SEL-849 receives start/stop commands with Ethernet-based industrial control protocols, contact inputs, or the remote HMI Start and Stop pushbuttons. The compact form-factor—71.1 mm (2.8 in) X 127.0 mm (5 in) X 152.4 mm (6 in)—easily installs in MCC drawers and buckets. Built-in current transformers save room and reduce installation time.

Telemetry Functionality

The SEL-849 is an excellent choice for telemetry applications for monitoring, metering, and control. Its small size, low cost, multiple communications options, and remote HMI options make the relay a perfect option for power distribution systems for such uses as end-of-line monitoring and power metering.

Easy-to-Use Web Interface

The web interface makes it easy for electricians and technicians to configure and monitor the SEL-849.

Easy Integration With Control Systems

Several communications protocol options, such as IEC 61850 Edition 1 and EtherNet/IP, allow the SEL-849 to be used with old and new control systems. Pick multiple sessions of Modbus TCP, Modbus serial, DNP3 LAN/WAN, or DNP3 serial for custom configuration of your applications. When dual Ethernet ports are selected, the relay also supports IEC 62439 PRP and fast failover switching. For maximum flexibility, the SEL-849 includes options for internally wetted or externally wetted contact inputs.

Arc-Flash Hazard Protection

MCCs typically have large fault-current potential, resulting in increased arc-flash hazards. The SEL-849 relay’s arc-flash detection capability significantly reduces total arc-flash energy.

Rugged Hardware You Can Rely On

All SEL relays are designed to operate in harsh environments where other relays may fail. The SEL-849 operates in extreme conditions, with an operating temperature of –40° to +85°C, and is designed and tested to exceed applicable standards, including vibration, electromagnetic compatibility, and adverse environmental conditions.

- Low- and medium-voltage three-phase motor protection

- Overload and solid-state motor relay replacement

- Basic I/O hardware for simple integration

- Low- and medium-voltage three-phase motor protection

- Overload and solid-state motor relay replacement

- Full I/O hardware for advanced integration

- Dual Ethernet ports for backup fail-over communications channel

- Motor management relay with built-in arc-flash detection

- Low- and medium-voltage three-phase motor protection

- Overload and solid-state motor relay replacement

- Full I/O hardware for advanced integration

- Dual Ethernet ports for backup fail-over communications channel

- DNP3 and EtherNet/IP for integration into SCADA and plant control systems

- Conformally coated circuit boards for harsh environment applications

Minimum Software Version

| Product | Revision | Z Number | acSELerator QuickSet Version | SEL Grid Configurator Version |

|---|---|---|---|---|

| SEL-849 | R106-V2 | 003 | 6.6.0.0 |

Latest Firmware Versions

There are no firmware versions available for this product.

| Product | Revision | Firmware ID | Date Available | Serial Number |

|---|---|---|---|---|

| SEL-3421 | R107-V0 | SEL-3421-R107-V0-Z000000-D20250117 | 2/15/25 | ~3250450001 |

| SEL-3422 | R107-V0 | SEL-3421-R107-V0-Z000000-D20250117 | 2/15/25 | ~3250450001 |

| SEL-849 | R110-V0 | SEL-849-R110-V0-Z007004-D20250117 | 2/15/25 | ~3250450001 |

| SEL-849 | R109-V1 | SEL-849-R109-V1-Z006004-D20250117 | 2/15/25 | ~3250450001 |

| SEL-849 | R108-V3 | SEL-849-R108-V3-Z005003-D20250117 | 2/15/25 | ~3250450001 |

| SEL-849 | R107-V5 | SEL-849-R107-V5-Z004002-D20250117 | 2/15/25 | ~3250450001 |

| SEL-849 | R106-V8 | SEL-849-R106-V8-Z003002-D20250117 | 2/15/25 | ~3250450001 |

The Firmware IDs for older versions of the firmware can typically be found in Appendix A of the instruction manual.

Minimum Software Version

| Product | Revision | Z Number | acSELerator QuickSet Version | SEL Grid Configurator Version |

|---|---|---|---|---|

| SEL-849 | R106-V2 | 003 | 6.6.0.0 |

Instruction Manuals

Sales Resource Central access is required to view the content in this tab.

Sales Resource Central849 - Software Tab

Configuration

acSELerator QuickSet SEL-5030 Software

QuickSet is a tool for engineers and technicians to quickly and easily configure, commission, and manage power system devices. QuickSet includes a Graphical Logic Editor and a device template tool to reduce configuration time and streamline deployment.

Learn more and download on the QuickSet software page.

acSELerator Architect SEL-5032 Software

Architect allows users to configure and document IEC 61850 systems that include GOOSE, Sampled Values (SV), or Manufacturing Message Specification (MMS) communications. Architect automatically compares SCL files with IEC 61850 requirements to ensure standard compliance.

Learn more and download on the Architect software page.

Automated Data Collection

SEL Data Management and Automation (DMA) Application Suite

Available on the Blueframe platform, DMA applications automatically collect, store, and manage device-specific information like oscillography, Sequence of Events (SOE) data, device settings, and property information as well as provide automated password rotation and streamlined device audits.

Learn more on the DMA software page.

Visualization & Analysis

SEL-5601-2 Synchrowave Event Software

Synchrowave Event helps engineers diagnose a protective relay’s behavior during a power system fault. It is a powerful and easy-to-use solution for displaying and analyzing SEL relay event reports and COMTRADE files.

Learn more and download on the Synchrowave Event software page.