SEL-2411P

Pump Automation Controller

The SEL-2411P is a standalone, preconfigured, SCADA-ready system for control and monitoring of water and wastewater pump applications. It is a simple solution to monitor and control liquid level pump-up and pump-down applications, such as lift stations (pump-down) and wells or reservoirs (pump-up). The SEL-2411P is UL-listed and designed to withstand harsh water and wastewater environments and comes standard with conformal coating to protect against atmospheres where corrosive gases, fumes, or liquids are present. Flexible I/O options, communications protocols, and simple station settings allow easy integration into new or retrofit applications.

Starting At

$2,930Pump Control and Monitoring—The SEL-2411P is designed for lift stations, wells, booster stations, storm water pumping, tank and reservoir level monitoring and control, proportional chemical feeding, intrusion/fire/flood alarming, and ventilation applications. It provides pump-up and pump-down applications with local or remote operation capabilities that use analog level inducers, pressure switches, or float switches.

Failover Control—The SEL-2411P can operate independently from a master SCADA control system. Upon communications failure, the SEL-2411P fails over to a predefined operation mode. It monitors floats for out-of-sequence operations and monitors level transducers to alarm and fail over to float switches in the event of a detectable transducer failure.

Local Control—The LCD screen and simple user interface provide operators with the ability to monitor, control, and adjust set points locally.

Operations Monitoring and Alarming—The SEL-2411P continuously monitors itself for proper operation. It records and sends time-stamped notifications to operators for analysis and rapid maintenance dispatch for any desired parameters. It also records daily and total run times, starts/stops, level alarm conditions, and pump failures.

Remote Pump Operations—The nonproprietary built-in pump alternator control exercises pumps without manual intervention for simplex, duplex, and triplex applications and allows easy customization for complex applications.

Diagnostics and Troubleshooting—The SEL-2411P performs subsecond time-stamped digital and analog event logging that provides an audit trail for operational data changes and other key data reliability indicators.

Features

-

- 1

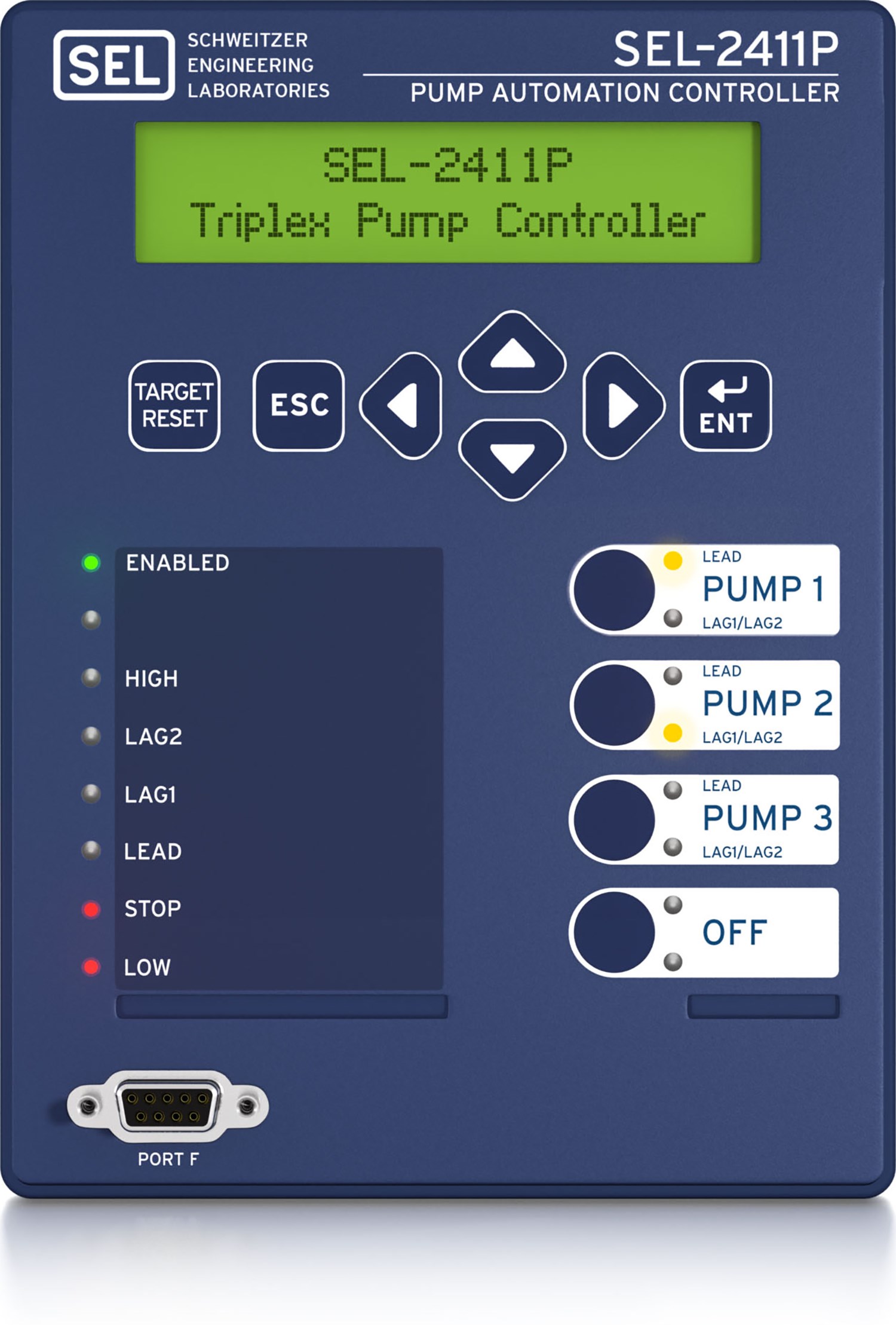

Large 2 × 16 character LCD

- 2

Simple front-panel navigation enables easy access to device configuration, detailed I/O status, alarms, and measured values

- 3

7 programmable LEDs to indicate I/O activity and device status

- 4

LEDs to indicate control state

- 5

Local controls with easy-to-use push-buttons enable and disable motors

- 6

Slide-in configurable labels

- 7

Slide-in configurable labels

- 8

Built-in EIA-232 serial port

12345678

-

-

- 1

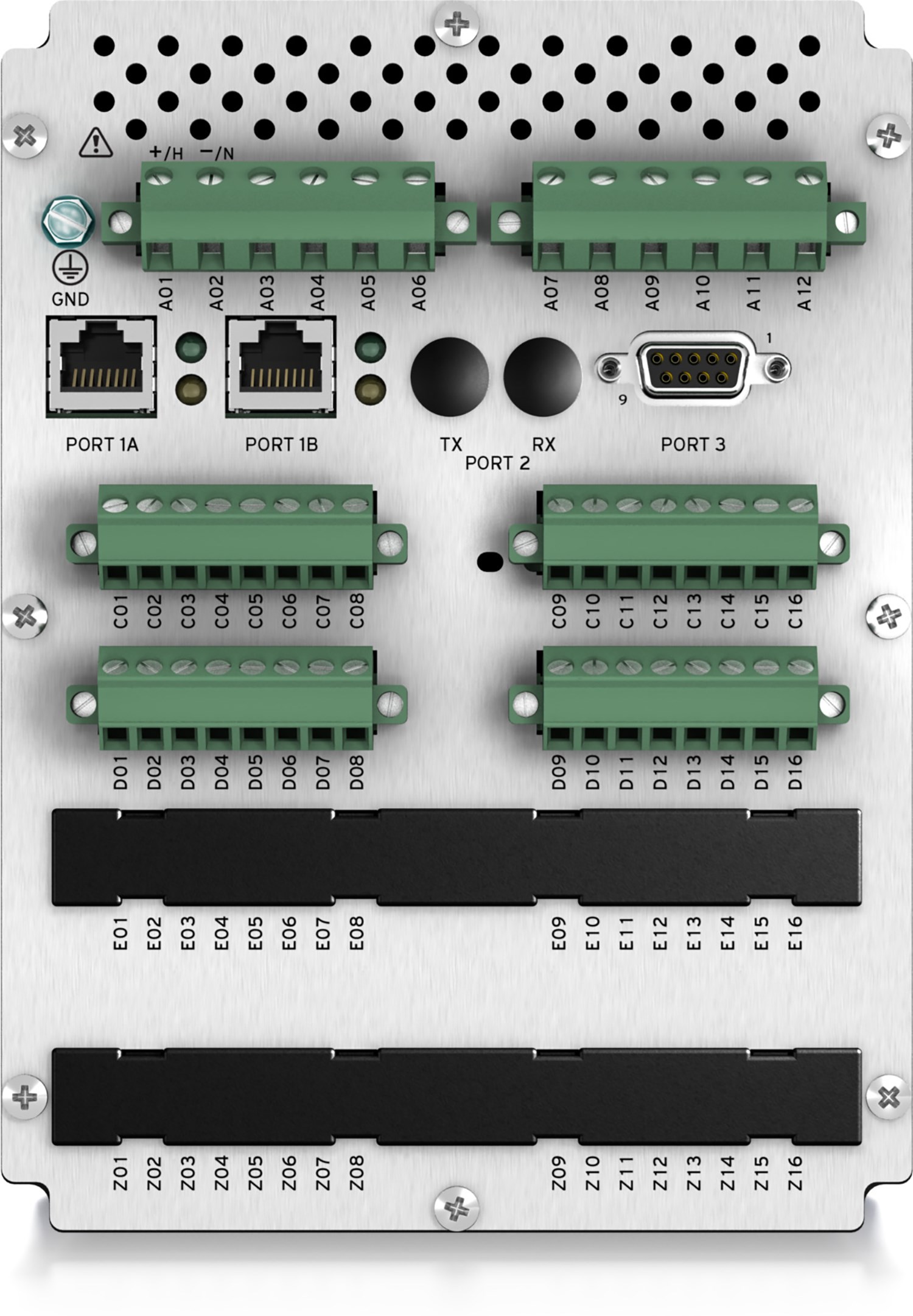

Power supply options include 24/48 Vdc, 125/250 Vdc, 120/240 Vac, and 50/60 Hz

- 2

Dual copper Ethernet ports include Modbus TCP, DNP3, and SEL protocols

- 3

One rear-panel EIA-232 serial port

- 4

Position for two optional cards to add analog I/O, additional digital I/O, or ac voltage and current inputs

1234

-

Details

High Reliability and Rugged Design

The SEL-2411P is UL-listed and designed to withstand vibration, electrical surges, fast transients, and extreme operating temperatures of –40º to +85ºC (–40º to +185ºF), and it has Class 1, Division 2 Hazardous Location Approval. We offer superior specification compliance and overall cost advantages, such as higher reliability, a lower purchase price, and no-charge configuration software with no reoccurring licensing fees. The SEL-2411P is protected by a worldwide, ten-year product warranty. For even harsher environments, the SEL-2411P comes standard with conformal coating to protect against airborne contaminants, such as chlorine, salt, and moisture.

Interoperable and SCADA-Ready Solution

The controller comes with a configured DNP3 map for scalable SCADA applications and includes the Modbus protocol as well as Ethernet and serial interfaces.

Interactive Station Settings

You can set the controller using the station settings tool for an interactive, simple, and quick configuration experience. Answering as few as four questions lets you customize the controller for any of the supported modes of operation:

- Single pump (well controller)

- Duplex pump controller

- Triplex station

- Triplex jockey

- Triplex high service

Flexible I/O for Local Control and System Applications

The base unit includes 20 digital inputs (DI) and 7 digital outputs (DO). Two additional card slots let you customize the I/O with the following card options:

- 14 DI card

- 8 DI card

- 8 DO card

- 8 analog input (AI) card

- 4 AI/4 analog output (AO) card

- 4 DI/4 DO card

- 4 DI/3 DO card

- 3 ac voltage input (AVI) phase monitor card

- 3 AVI/3 ac current input (ACI) card

Pump Diagnostic Reports

The SEL-2411P provides the following pump reports:

- Run time for the last 2 hr, 24 hr, and 48 hr and total run time per pump

- Pump start counts for the last 2 hr, 24 hr, and 48 hr and total starts per pump

Communications and Integration

The SEL-2411P includes two EIA-232 ports and two 10/100BASE-T Ethernet ports (front and back). Standard Ethernet protocols include Telnet, FTP, Modbus TCP, and DNP3 LAN/WAN. Standard serial protocols include Modbus RTU, Compressed ASCII, and SEL protocols, including SEL ASCII, SEL Mirrored Bits communications, and SEL Fast SER.

Convenient Customizable Controls

The front panel includes four programmable pushbuttons and status LEDs that can be customized to fit your application`s local control needs. You can print labels for seven front-panel LEDs to show the device status, critical I/O status, or results of logic calculations. You can also label the four pushbuttons and associated LEDs to simplify operator interaction.

Local Control With SELogic Control Equations

Program the SEL-2411P with powerful math and logic. You can use control equations with logic, arithmetic, analog comparison, and timer functions for automatic local control and to combine data into system information. Time-deterministic, high-speed processing is ideal for critical applications.

Customizable and Scalable Solution

Network, replicate, and standardize your pump control applications and interface across many facilities while maintaining the flexibility to customize for unique or standalone stations. The SEL-2411P simplifies standardization and support with documented features and functionality.

- Simplex/duplex/triplex pump controller

- Pump control for float switch level control

- Integration with SCADA

- Simplex/duplex/triplex pump controller

- Pump control for float switch level control and/or analog level control

- Integration with SCADA

- Simplex/duplex/triplex pump controller

- Pump control for float switch level control and/or analog level control

- Integration with SCADA

- AC voltage phase monitor with diagnostic waveform event reports to capture voltage sags, swells, and loss

Minimum Software Version

| Product | Revision | Z Number | acSELerator QuickSet Version | SEL Grid Configurator Version |

|---|---|---|---|---|

| SEL-2411P | R302-V1 | 003 | 6.10.7.0 | |

| SEL-2411P | R302-V0 | 003 | 6.10.7.0 | |

| SEL-2411P | R301-V1 | 002 | 6.8.2.0 | |

| SEL-2411P | R301-V0 | 002 | 6.8.2.0 | |

| SEL-2411P | R300-V0 | 001 | 6.6.0.0 |

Latest Firmware Versions

There are no firmware versions available for this product.

| Product | Revision | Firmware ID | Date Available | Serial Number |

|---|---|---|---|---|

| SEL-2411P | R302-V1 | SEL-2411P-R302-V1-Z003008-D20220311 | 5/23/22 | ~3221430001 |

The Firmware IDs for older versions of the firmware can typically be found in Appendix A of the instruction manual.

Minimum Software Version

| Product | Revision | Z Number | acSELerator QuickSet Version | SEL Grid Configurator Version |

|---|---|---|---|---|

| SEL-2411P | R302-V1 | 003 | 6.10.7.0 | |

| SEL-2411P | R302-V0 | 003 | 6.10.7.0 | |

| SEL-2411P | R301-V1 | 002 | 6.8.2.0 | |

| SEL-2411P | R301-V0 | 002 | 6.8.2.0 | |

| SEL-2411P | R300-V0 | 001 | 6.6.0.0 |

Instruction Manuals

Sales Resource Central access is required to view the content in this tab.

Sales Resource Central2411P - Software Tab

Configuration

acSELerator QuickSet SEL-5030 Software

QuickSet is a tool for engineers and technicians to quickly and easily configure, commission, and manage power system devices. QuickSet includes a Graphical Logic Editor and a device template tool to reduce configuration time and streamline deployment.

Learn more and download on the QuickSet software page.

Automated Data Collection

SEL Device Management and Automation (DMA) Application Suite

Available on the Blueframe platform, DMA applications automatically collect, store, and manage device-specific information like oscillography, Sequence of Events (SOE) data, device settings, and property information. They also provide automated password rotation and streamlined device audits.

Learn more on the DMA software page.

Visualization & Analysis

SEL-5601-2 Synchrowave Event SOFTWARE

Synchrowave Event helps engineers diagnose the cause of power system disturbances, including faults. It is a powerful and easy-to-use solution for displaying and analyzing SEL event reports and COMTRADE files.

Learn more and download on the Synchrowave Event software page.

.jpg?n=63882071284000)

.png?n=63666931842000)