SEL-487B

Bus Differential and Breaker Failure Relay

The SEL-487B provides optimized, low-impedance bus differential fault detection by using high-speed, subcycle protection coupled with high-security operation for external faults. Superior protection performance is combined with integrated station automation features for seamless transition into new and retrofit applications.

Transform the way you modernize your substation with optional Time-Domain Link (TiDL) technology or Sampled Values (SV)-based technology using IEC 61850-9-2.

Starting At

$8,950Low-Impedance Bus Differential Protection—Provide flexible low-impedance bus differential protection for various busbar topologies and sizes. You can protect systems with up to 21 three-phase bus terminals by using three relays to provide 6 three-phase differential bus zones and 3 independent check zones. Patented open CT detection algorithms block potential misoperations due to open or shorted CT conditions.

Integrated Overcurrent Protection—Choose from ten overcurrent curves for each current input for additional protection. Each torque-controlled time-overcurrent element has two reset characteristics. There is also one level of instantaneous and definite-time elements available for each current input.

Voltage Elements—Supervise current differential tripping within the relay by using voltage elements. Three separate voltage elements consist of two levels of phase under- and overvoltage elements and two levels of negative- and zero-sequence overvoltage elements for each of the three analog voltage quantities measured.

10:1 CT Ratio Mismatch—Install the SEL-487B in a system with nondedicated CTs, with CT ratio mismatches up to 10:1. This allows the same CTs to be used in other protection applications, such as metering or backup relaying.

Dynamic Zone Configuration—Automatically reassign current inputs to different bus zones without using auxiliary relays. The SEL-487B is suited for bus topologies that include bus-tie breakers and disconnects.

Breaker Failure Detection—Mitigate circuit breaker failure with the SEL-487B relay’s integrated circuit breaker failure detection and logic, which includes retrip capability for each terminal.

Integration and Automation—Select from an array of communications features and protocols to integrate the SEL-487B into your existing communications schemes. The relay features EIA-232 as well as optional copper or fiber Ethernet ports to fit into an array of applications. Protocol options include Mirrored Bits communications, DNP3 LAN/WAN, the Simple Network Time Protocol (SNTP), the Parallel Redundancy Protocol (PRP), the IEEE 1588 Precision Time Protocol Version 2 (PTPv2), and IEC 61850 Edition 2.

Digital Secondary System Technologies—SEL TiDL and SV-based solutions replace copper with fiber to increase safety, improve reliability, and limit the impact of an electromagnetic pulse. Apply the SEL-487B-2 TiDL relay with the SEL-TMU TiDL Merging Unit in the field to provide remote I/O and digitize analog signals. This simple point-to-point solution with a strong cybersecurity posture is easy to implement. Apply the IEC 61850-compliant SEL-487B-2 SV relay to receive SV data from a remote merging unit via a network. Improve system availability in SV applications with PRP or seamless failover using a five-port Ethernet card.

Flexible Communications Options—Use small form-factor pluggable (SFP) transceivers on designated process bus, station bus, and engineering access ports in the five-port Ethernet card. Choose between single- and multimode communications options for increased flexibility. All ports support 100 Mbps SFP transceivers, and process bus ports also support 1 Gbps SFP transceivers.

Distributed Bus Protection—Apply the SEL-487B in a distributed bus protection scheme using TiDL technology. The system is easily scalable for the number of bays in your system, and it does not require special communications ports or network engineering.

Features

-

- 1

EIA-232 serial port is quick and convenient for system setup and local access.

- 2

LCD automatically scrolls between custom displays.

- 3

Easy-to-use keypad aids simple navigation.

- 4

LEDs indicate custom alarms and provide fast and simple information to assist dispatchers and line crews with rapid power restoration.

- 5

Programmable operator pushbuttons with user-configurable labels allow customization.

12345

-

-

- 1

Choose from a horizontal panel-mount or rack-mount chassis and different size options.

- 2

Communications protocols include FTP, Telnet, DNP3 LAN/WAN, PRP, IEC 61850 Edition 2 (optional feature), and IEEE 1588 PTPv2.

- 3

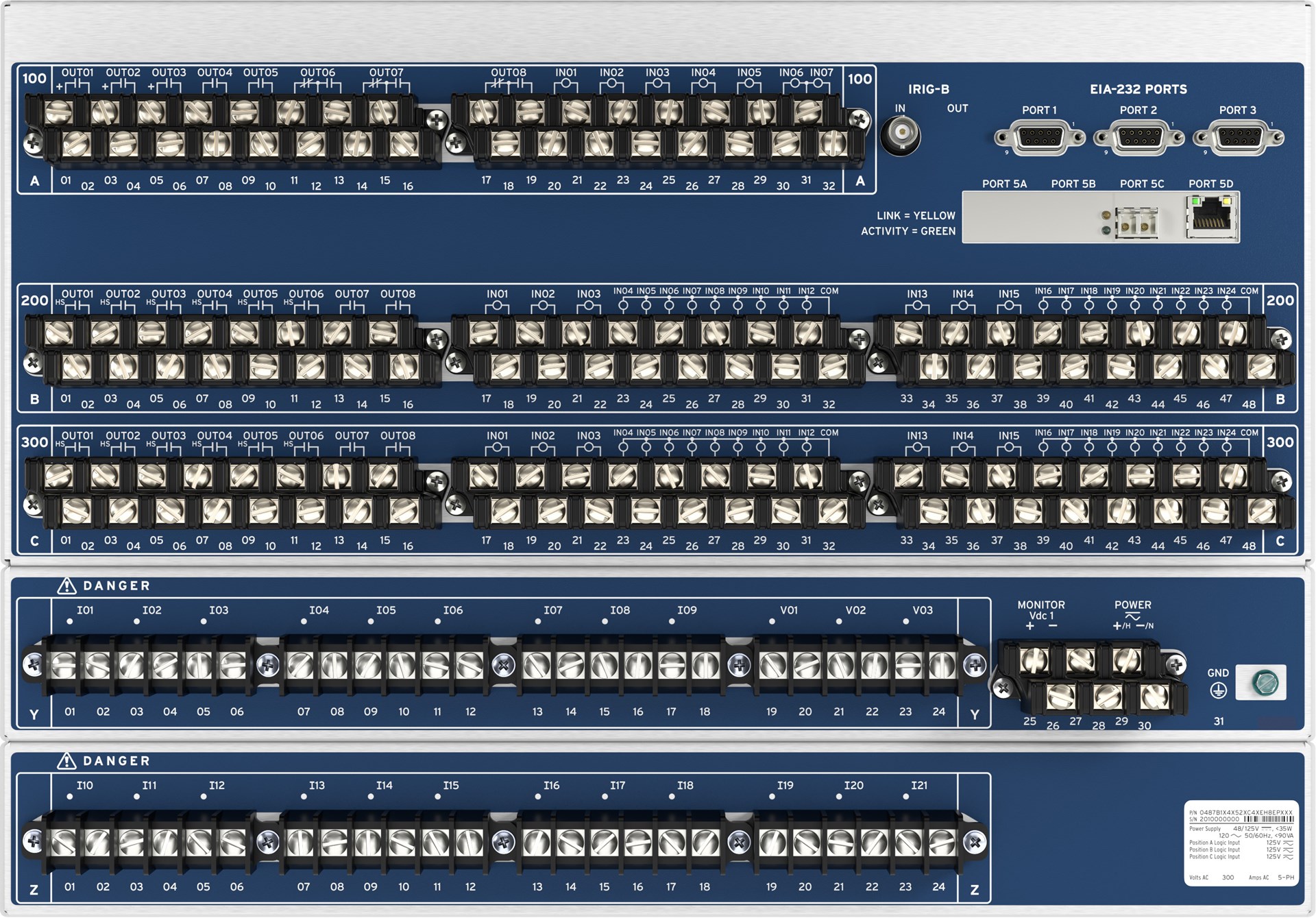

Use the three EIA-232 ports for Mirrored Bits communications, DNP3, SCADA, and engineering access.

- 4

21 current and 3 voltage channels accommodate different busbar configurations.

- 5

Choose from power supply options such as 24–48 Vdc; 48–125 Vdc or 110–120 Vac; or 125–250 Vdc or 110–240 Vac.

12345

-

-

- 1

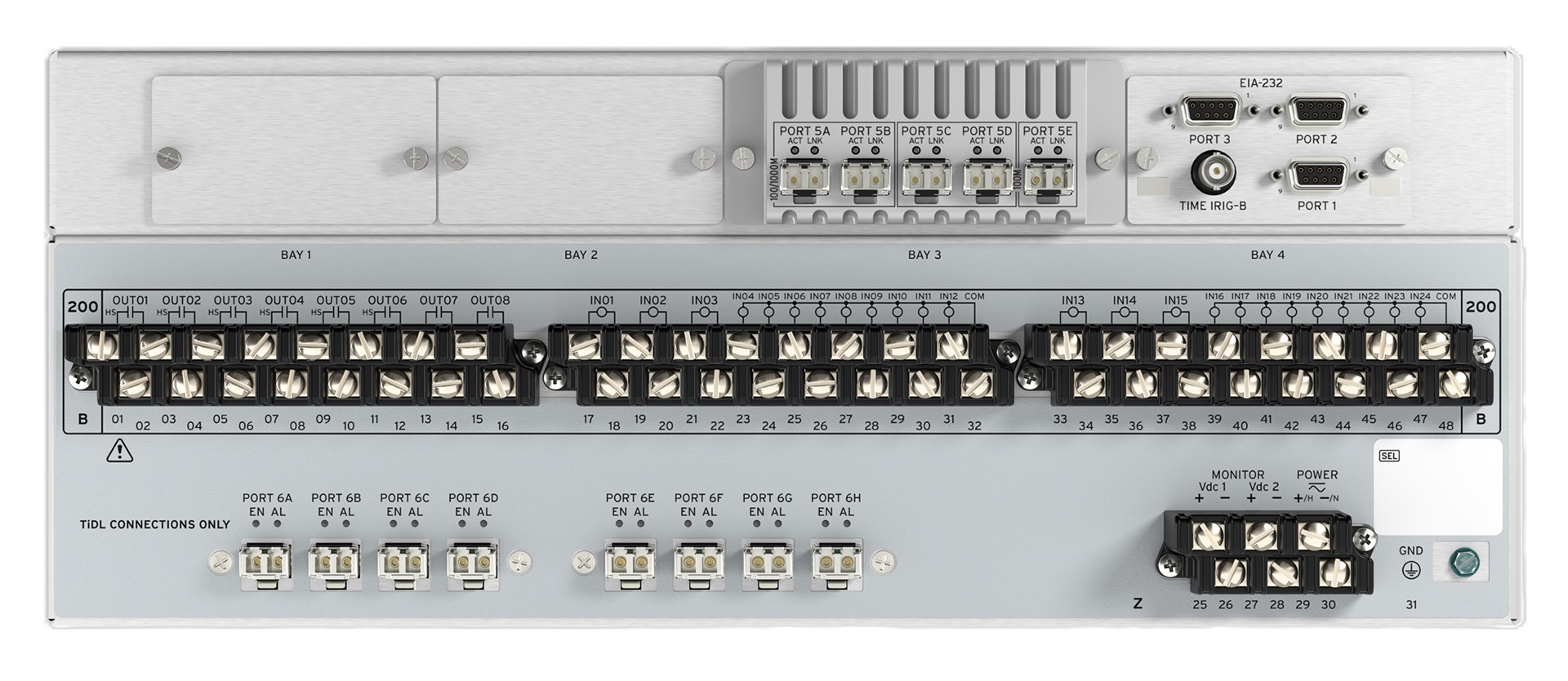

4U chassis with horizontal mounting options (panel or rack) accommodates your application needs.

- 2

LEDs indicate the connection status to an SEL-TMU on a per-port basis.

- 3

Eight SFP ports allow the TiDL relay to connect with eight remote SEL-TMU devices and to receive remote analog and digital data.

- 4

Select a five-port Ethernet communications card for dedicated station bus and engineering access ports.

1234

-

-

- 1

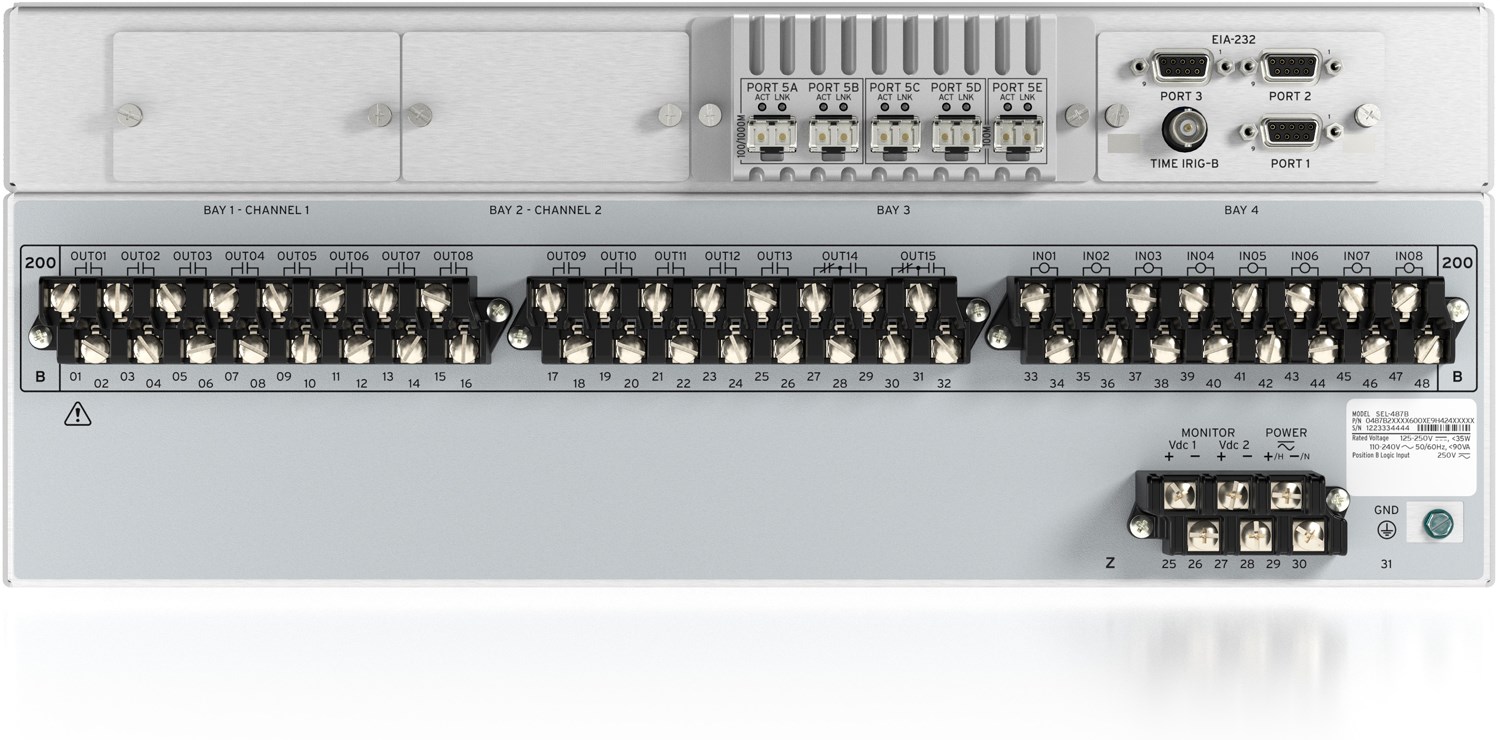

The 4U chassis has various mounting options to accommodate hardware needs.

- 2

Select a five-port Ethernet communications card for dedicated process bus, station bus, and engineering access ports.

12

-

Details

Protection

Provide flexible, subcycle, low-impedance bus differential protection for various busbar topologies and sizes with the SEL-487B. You can protect systems that have up to 21 three-phase bus terminals by using three relays to provide 6 three-phase differential bus zones and 3 independent check zones. To optimize protection security, the check zones supervise the system on a per-phase basis and a patented open-CT detection algorithm blocks potential misoperations during open- or shorted-CT conditions. Directional and low-impedance differential current elements provide increased security and fast fault detection. Built-in breaker failure protection reduces protection costs.

Flexibility

Apply the same CT for differential protection, metering, backup relaying, or other functions. The SEL-487B can use nondedicated CTs with ratio mismatches up to 10:1.

Automation and Control

Reduce project costs and simplify interconnect wiring using multiple communications protocols. Configurable operator controls and simplified variable naming provide added power to SELogic control equations.

Monitoring and Metering

Provide accurate, timely monitoring and metering of busbar, feeder, and substation signals. Terminal currents, breaker and disconnect positions, station dc power levels, and three-phase voltage are continuously monitored and updated. You can eliminate external recorder and metering requirements with oscillographic and binary COMTRADE event reports and Sequential Events Recorder (SER) reporting.

Three Independent Check Zones

Improve power system availability and reliability by reducing unintentional relay operations due to failed or misaligned disconnect auxiliary contacts, and provide redundant verification of in-zone faults. Independent check zone settings offer additional flexibility for adjusting the check zone differential element.

Advanced Open CT Detection

Improve the security of the current differential element with patented open CT detection logic. It assures current differential bus zones will not misoperate due to terminals that can’t be properly measured.

Enhanced Front-Panel HMI

Improve efficiency and simplify installation with more target LEDs and operator pushbuttons. The 7U and 9U chassis have options for an additional 8 target LEDs and 4 operator pushbuttons, providing 24 target LEDs and 12 operator pushbuttons on the front-panel HMI.

SEL TiDL-Based Solutions

Apply a TiDL-based process bus solution, where SEL-TMU devices are placed in the yard close to the primary equipment to digitize discrete I/O signals and analog data. SEL-TMU units exchange these data with an SEL-487B-2 TiDL relay in the control house. Each SEL-TMU can share data with as many as four TiDL relays, providing protection design flexibility.

TiDL combines the proven protection of the SEL-400 series relays with the purpose-built SEL-TMU, simplifying deployment, reducing training requirements, and increasing availability. TiDL technology uses point-to-point connections and a non-Ethernet protocol, providing a simple and secure solution. TiDL also provides built-in data synchronization and synchronous sampling, ensuring protection is available in the relay regardless of whether an external time signal is available.

SEL SV-Based Solutions

Based on the IEC 61850 standard, SV-based solutions maximize flexibility and interoperability. The SEL-401 Protection, Automation, and Control Merging Unit and the SEL-421-7 Protection, Automation, and Control System Merging Unit digitize analog signals from primary equipment and send them using the SV protocol to an SEL-487B-2 relay in the control house. Because all SEL SV devices are compliant with IEC 61850-9-2 and the UCA 61850-9-2LE guideline, the SEL-487B-2 SV relay can be used with other manufacturers’ IEC 61850-compliant units.

Flexible Ethernet Communications

The two-, four-, and five-port Ethernet communications card options enable you to communicate using a variety of protocols, including FTP, HTTP, DNP3, PTPv2, PRP, Telnet, synchrophasors, and IEC 61850 Edition 2.

The TiDL and SV relays can be configured with a five-port Ethernet card supporting PRP or failover functionality to increase system availability, as well as PTPv2 on process bus or station bus ports for time synchronization. Use network monitoring features in the relay to further improve system availability by actively monitoring each redundant path to detect communications network failures.

The five-port card also features dedicated ports and IP addresses for station bus and engineering access networks to provide selective access control. All ports support SFP transceivers. Single- and multi-mode communications options provide increased flexibility. All ports support 100 Mbps SFP transceivers, and process bus ports also support 1 Gbps SFP transceivers.

Serial Communications

All four independent EIA-232 serial ports support SEL Fast Message, SEL ASCII, Compressed ASCII, SEL Fast Operate, SEL Fast Meter, SEL Fast SER, enhanced SEL Mirrored Bits communications, and DNP3 Level 2 Outstation as well as dial-out, Virtual Terminal, and communications with SEL-2600 series RTD modules.

Simplified Settings Management

Use acSELerator QuickSet SEL-5030 Software to develop relay settings offline and program SELogic control equations. Configure the TiDL and SV relays using SEL Grid Configurator, a software tool that increases efficiency and improves settings insights. It features a spreadsheet-style editor, protection visualization, comprehensive reporting, custom filters, and multiple-device settings management.

- 21-terminal low-impedance bus differential protection

- Overcurrent elements and breaker failure detection

- Comprehensive communications protocols, including IEC 61850 Edition 2

- TiDL relay for a digital secondary system

- Eight fiber ports (to connect to SEL-TMU TiDL Merging Units) in place of the current and voltage analog inputs

- Low-impedance bus differential protection for seven 3-phase feeders

- Overcurrent elements and breaker failure detection

- Comprehensive communications protocols

- IEC 61850-9-2 Sampled Values relay for a digital secondary system solution

- Low-impedance bus differential protection for seven 3-phase feeders

- Overcurrent elements and breaker failure detection

- Comprehensive communications protocols

Minimum Software Version

Latest Firmware Versions

There are no firmware versions available for this product.

| Product | Revision | Firmware ID | Date Available | Serial Number |

|---|---|---|---|---|

| SEL-487B | R124 | SEL-487B-R124-V0-Z008004-D20131111 | 11/19/13 | 1133230001 |

| SEL-487B-1 | R318-V1 | SEL-487B-1-R318-V1-Z018007-D20240509 | 5/22/24 | ~1241430001 |

| SEL-487B-2 | R405-V0 | SEL-487B-2-R405-V0-Z104101-D20240509 | 5/22/24 | ~1241430001 |

The Firmware IDs for older versions of the firmware can typically be found in Appendix A of the instruction manual.

Minimum Software Version

Instruction Manuals

Sales Resource Central access is required to view the content in this tab.

Sales Resource Central411L 421 451 487B 487E - Software Tab

Configuration Software

acSELerator QuickSet SEL-5030 Software

QuickSet is a tool for engineers and technicians to quickly and easily configure, commission, and manage power system devices. QuickSet includes a Graphical Logic Editor and a device template tool to reduce configuration time and streamline deployment.

Learn more and download on the QuickSet software page.

SEL-5037 Grid Configurator Software

SEL Grid Configurator is a no-charge software tool for engineers and technicians to create, manage, and deploy settings for SEL power system devices.

Learn more and download on the Grid Configurator software page.

acSELerator Architect SEL-5032 Software

Architect allows users to configure and document IEC 61850 systems that include GOOSE, Sampled Values (SV), or Manufacturing Message Specification (MMS) communications. Architect automatically compares SCL files with IEC 61850 requirements to ensure standard compliance.

Learn more and download on the Architect software page.

Automated Data Collection

SEL Data Management and Automation (DMA) Application Suite

Available on the Blueframe platform, DMA applications automatically collect, store, and manage device-specific information like oscillography, Sequence of Events (SOE) data, device settings, and property information. They also provide automated password rotation and streamlined device audits.

Learn more on the DMA software page.

Visualization and Analysis

SEL-5601-2 synchroWAVe Event Software

synchroWAVe Event helps engineers diagnose a protective relay’s behavior during a power system fault. It is a powerful and easy-to-use solution for displaying and analyzing SEL relay event reports and COMTRADE files.

Learn more and download on the synchroWAVe Event software page.