SEL-451

Protection, Automation, and Bay Control System

The SEL-451 is a complete standalone system. It has the speed, power, and flexibility to combine complete substation bay control with high-speed breaker protection in one economical system. You can use the SEL-451 as an integral part of a full substation protection, control, and monitoring solution. It reduces maintenance costs by accurately tracking the breaker operation. By monitoring breaker interruption times and the accumulated breaker duty, the SEL-451 helps you easily determine the need for proactive maintenance. You can integrate information with SCADA or automation systems through a communications processor or directly to the Ethernet port.

Transform the way you modernize your substation with optional Time-Domain Link (TiDL) technology or Sampled Values (SV)-based technology using IEC 61850-9-2.

Starting At

$5,520Dual Breaker Bay Control—Meet your bay control needs with complete two-breaker control and high-speed breaker failure detection. You can easily control motor-operated switches, capacitor banks, and field I/O from the relay front panel or remotely. Configurable labels enable customization of relay controls to match your application.

Rapid Bay Control Commissioning—Choose among different bus configurations, including single- and dual-busbar, transfer bus, tie-breaker, breaker-and-a-half, ring-bus, double-bus/ double-breaker, and source-transfer configurations. These bus arrangements allow easy status and control of as many as 20 disconnect switches and two breakers.

High-Impedance Fault Detection—Detect high-impedance faults with Arc Sense technology (AST). High-impedance faults are a common result of a downed conductor on surfaces with poor conductivity. With AST, the SEL-451 alarms or trips for faults that produce low fault current and are undetectable with conventional overcurrent relays.

Complete Overcurrent Protection—Customize distribution protection with multiple instantaneous and time-overcurrent elements combined with SELogic control equations. Best Choice Ground Directional Element logic optimizes directional element performance and eliminates the need for many directional settings.

Pad-Mounted Switchgear Protection—Protect pad-mounted switchgear with low-energy analog (LEA) voltage inputs; this helps you save in overall system cost by eliminating the need for amplification electronics between the line sensor and the relay. Having fewer devices also leads to a simpler system, a reduction in labor costs, and the elimination of a possible point of failure.

Breaker Wear Monitoring—Compare published data from the breaker’s manufacturer to the actual interrupted current and number of operations for two breakers, and create alarms accordingly. You can monitor mechanical and electrical interruption time per pole, comparing average and last trip times for maintenance scheduling.

Digital Secondary System Technologies—SEL TiDL and SV-based solutions replace copper with fiber to increase safety, improve reliability, and limit the impact of an electromagnetic pulse. Apply the SEL-451-6 TiDL relay with the SEL-TMU TiDL Merging Unit in the field to provide remote I/O and digitize analog signals. This simple point-to-point solution with a strong cybersecurity posture is easy to implement. Apply the IEC 61850-compliant SEL-451-6 SV relay to receive SV data from a remote merging unit via a network, or apply the SEL-451-6 SV merging unit to publish SV data to remote SV relays in the control house. Improve system availability in SV applications with the Parallel Redundancy Protocol (PRP) or seamless failover using a five-port Ethernet card.

Flexible Communications Options—Use small form-factor pluggable (SFP) transceivers on designated process bus, station bus, and engineering access ports in the five-port Ethernet card. Choose between single- and multimode communications options for increased flexibility. All ports support 100 Mbps SFP transceivers, and process bus ports also support 1 Gbps SFP transceivers.

Features

-

- 1

EIA-232 front serial port is quick and convenient for system setup and local access.

- 2

Interactive bay display with user-configurable apparatus labels allows the operator to view the status of breakers and disconnect switches and to control them.

- 3

Easy-to-use keypad aids simple navigation.

- 4

Front-panel LEDs indicate custom alarms and provide fast and simple information to assist dispatchers and line crews with rapid power restoration.

- 5

Programmable operator pushbuttons with user-configurable labels allow front-panel customization.

12345

-

-

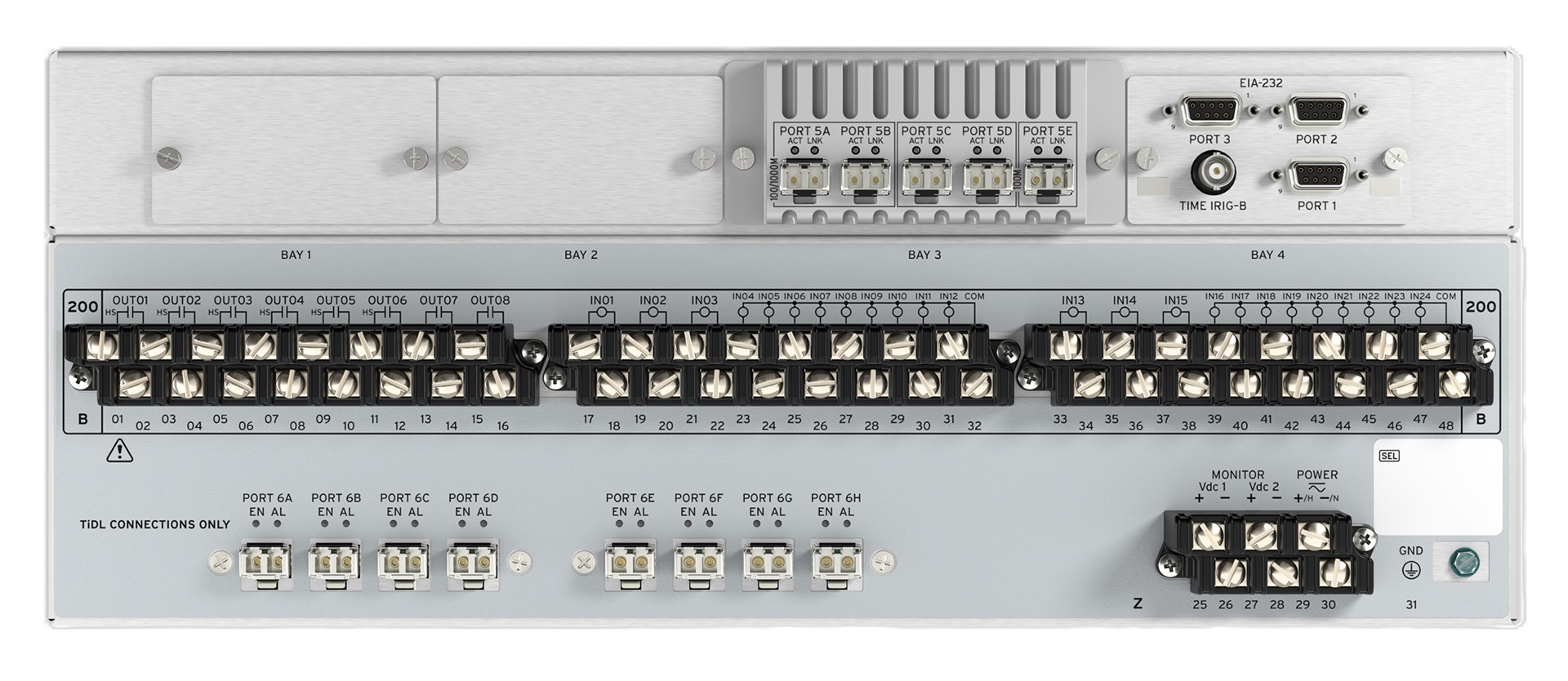

- 1

Choose from a vertical or horizontal, panel-mount or rack-mount chassis and different size options.

- 2

Use a maximum of 68 output contacts. Requires 8U chassis.

- 3

Communications protocols include FTP, Telnet, synchrophasors, DNP3 LAN/WAN, PRP, IEC 61850 Edition 2 (optional feature), and the IEEE 1588 Precision Time Protocol Version 2 (PTPv2).

- 4

Use three rear EIA-232 ports for Mirrored Bits communications, DNP3, SCADA, and engineering access.

- 5

Use a maximum of 103 input contacts. Requires 8U chassis.

- 6

Order six current inputs in standard terminal blocks (as shown) or a Connectorized hardware configuration.

- 7

Choose six voltage inputs in either standard terminal blocks, a Connectorized hardware configuration, or a low-energy analog (LEA) hardware configuration.

- 8

Power supply options include: 24–48 Vdc; 48–125 Vdc or 110–120 Vac; or 125–250 Vdc or 110–240 Vac.

12345678

-

-

- 1

4U chassis with mounting options (vertical or horizontal; panel or rack) accommodates your application needs.

- 2

Select a five-port Ethernet communications card for dedicated station bus and engineering access ports.

- 3

LEDs indicate the connection status to an SEL-TMU on a per-port basis.

- 4

Eight SFP ports allow the TiDL relay to connect with eight remote SEL-TMU devices and to receive remote analog and digital data.

1234

-

-

- 1

The 4U chassis has various mounting options to accommodate hardware needs.

- 2

Select a five-port Ethernet communications card for dedicated process bus, station bus, and engineering access ports.

12

-

-

- 1

Chassis options (for up to three I/O boards) and mounting options accommodate hardware needs.

- 2

Select a five-port Ethernet card for dedicated process bus, station bus, and engineering access ports.

- 3

Six current and six voltage analog inputs support signal digitization and local protection schemes.

123

-

Details

Bay Control for Two Breakers

Complete two-breaker control and breaker failure complement the versatility of the SEL-451 programmable logic to meet your bay control needs. Easily control motor-operated switches, capacitor banks, and field I/O from the front panel or remotely. Configurable labels make it easy to customize relay controls to match your application.

Transformer Inrush Harmonic Monitoring

Apply the second-, fourth-, and fifth-harmonic elements with individual threshold settings to detect transformer energization and overexcitation conditions. The output from these harmonic detection elements can be used for a variety of functions, including modification of relay settings to improve security and event reporting to make identification of transformer energization events fast and simple.

Maximize the Capability of Substation Equipment

Fully load equipment by monitoring power, including thermal or rolling interval demand as well as peak demand on positive-, negative-, and zero-sequence current. Use the full capacity of the equipment while maintaining SEL quality protection.

Advanced Visualization Tools

The SEL-451 offers a configurable HMI for easy integration into your application or operating standards. HMI tools include custom metering and status displays, direct pushbutton access, critical information alarms in chronological order, a rotating display, and time-stamped SER reports. You can reduce errors by automatically scrolling between one-line bay diagrams, custom metering displays, and alarms

Improve Operation With IEEE Synchrophasor Data

Give operators critical system information via serial or Ethernet communications. With the SEL-451, you get the required substation protection, monitoring, and control in addition to a built-in phasor measurement unit at each substation. The relay makes control decisions based on voltage, current, or frequency data from other relays. The synchrophasor real-time control (RTC) capability makes this information available for local or system-wide control and automation.

Digital Fault Recording (DFR)

Combine relaying reliability with true DFR functionality. The SEL-451 Relay’s high-speed sampling (8 kHz) and COMTRADE output provide advanced oscillography. The acSELerator QuickSet SEL-5030 Software graphical user interface makes it easy to view harmonic analysis and events.

High-Accuracy Timestamping

Time-tag binary COMTRADE event reports with real-time accuracy of better than 10 µs. You can view system state information at the time of faults, or with timed triggers, across the entire system. This system state information helps validate system models and improve transfer limits and system stability.

Integrate Many Substation Devices Into One Powerful System Using the SEL-451

Control cooling fans, motor-operated switches, or other equipment using the processing and I/O of the SEL-451. Hardware options let you expand I/O up to 103 inputs or 68 outputs.

Expanded SELogic Control Equations

Use math and logic combinations of analog and digital values for customized applications, adapt system control based on prefault conditions, and scale analog values and latch momentary inputs for SCADA retrieval.

Voltage Sag, Swell, and Interruption (VSSI) Report

Capture power quality data related to voltage disturbances over a long period of time.

Built-In Web Server

Access basic relay information on a standard Ethernet network with the built-in web server. You can view relay status, Sequential Events Recorder (SER) information, metering information, and settings with easy access within a local network. The web server access requires a relay password and is limited to read-only viewing of information.

SEL TiDL-Based Solutions

Apply a TiDL-based process bus solution, where SEL-TMU devices are placed in the yard close to the primary equipment to digitize discrete I/O signals and analog data. SEL-TMU units exchange these data with an SEL-451-6 TiDL relay in the control house. Each SEL-TMU can share data with as many as four TiDL relays, providing protection design flexibility.

TiDL combines the proven protection of the SEL-400 series relays with the purpose-built SEL-TMU, simplifying deployment, reducing training requirements, and increasing availability. TiDL technology uses point-to-point connections and a non-Ethernet protocol. TiDL also provides built-in data synchronization and synchronous sampling, ensuring protection is available in the relay regardless of whether an external time signal is available.

SEL SV-Based Solution

Based on the IEC 61850 standard, SV-based solutions maximize flexibility and interoperability. The SEL-451-6 can be ordered as a merging unit to digitize analog signals from primary equipment and send them using the IEC 61850-9-2 SV protocol to IEC 61850-compliant relays in the control house. The SEL-451-6 can also be ordered as a relay to perform protective functions and other control actions based on the SV data streams it subscribes to.

- SV Merging Unit—The SEL-451-6 merging unit comes with complete feeder protection and bay control built in. This allows you to have the protection right next to the primary equipment for increased speed and reliability as well as to easily transmit the SV data streams to subscriber relays in the control house for redundant protection.

- SV Relay—The SEL-451-6 relay offers feeder protection and bay control and can also receive SV data from devices such as SEL SV merging units.

Because all SEL SV devices are compliant with IEC 61850-9-2 and the UCA 61850-9-2LE guideline, the SEL-451-6 can be used with primary equipment that generates similar SV streams or with other manufacturers’ IEC 61850-compliant units.

Flexible Ethernet Communications

The two-, four-, and five-port Ethernet communications card options enable you to communicate using a variety of protocols, including FTP, HTTP, DNP3, PTPv2, PRP, Telnet, synchrophasors, and IEC 61850 Edition 2.

The TiDL and SV relays can be configured with a five-port Ethernet card supporting PRP or failover functionality to increase system availability, as well as the Precision Time Protocol Version 2 (PTPv2) on process bus or station bus ports for time synchronization. Use network monitoring features in the relay to further improve system availability by actively monitoring each redundant path to detect communications network failures.

The five-port card also features dedicated ports and IP addresses for station bus and engineering access networks to provide selective access control. All ports support SFP transceivers. Single- and multimode communications options provide increased flexibility. All ports support 100 Mbps SFP transceivers, and process bus ports also support 1 Gbps SFP transceivers.

Serial Communications

All four independent EIA-232 serial ports support SEL Fast Message, ASCII, Compressed ASCII, Extended Fast Meter, Fast Operate, Fast SER, SEL Mirrored Bits communications, Ymodem, and DNP3 Level 2 Outstation as well as dial-out, Virtual Terminal, and communications with SEL-2600 series RTD modules.

Simplified Settings Management

Use acSELerator QuickSet SEL-5030 Software to develop relay settings offline and program SELogic control equations. Configure the TiDL and SV relays using SEL Grid Configurator, a software tool that increases efficiency and improves settings insights. It features a spreadsheet-style editor, protection visualization, comprehensive reporting, custom filters, and multiple-device settings

- Feeder protection

- Dual-breaker bay control and breaker wear monitoring

- Feeder protection

- Dual-breaker bay control and breaker wear monitoring

- High-impedance fault detection

- Comprehensive communications protocols, including IEC 61850 Edition 2, and additional I/O

- TiDL relay for a digital secondary system solution

- Eight fiber ports (to connect to SEL-TMU TiDL Merging Units) in place of the current and voltage analog inputs

- Feeder protection

- Dual-breaker bay control and breaker wear monitoring

- Comprehensive communications protocols

- IEC 61850-9-2 Sampled Values relay for a digital secondary system solution

- Feeder protection

- Dual-breaker bay control and breaker wear monitoring

- Comprehensive communications protocols

Minimum Software Version

Latest Firmware Versions

There are no firmware versions available for this product.

| Product | Revision | Firmware ID | Date Available | Serial Number |

|---|---|---|---|---|

| SEL-451-1 | R202 | SEL-451-1-R202-V0-Z004004-D20090213 | 2/27/09 | ~2009058001 |

| SEL-451-2 | R126 | SEL-451-2-R126-V0-Z100011-D20121207 | 12/21/12 | ~1123560001 |

| SEL-451-4 | R126 | SEL-451-4-R126-V0-Z100011-D20121207 | 12/21/12 | ~1123560001 |

| SEL-451-5 | R328-V1 | SEL-451-5-R328-V1-Z031014-D20240509 | 5/22/24 | ~1241430001 |

| SEL-451-6 | R406-V0 | SEL-451-6-R406-V0-Z106102-D20240509 | 5/22/24 | ~1241430001 |

The Firmware IDs for older versions of the firmware can typically be found in Appendix A of the instruction manual.

Minimum Software Version

Instruction Manuals

Sales Resource Central access is required to view the content in this tab.

Sales Resource Central411L 421 451 487B 487E - Software Tab

Configuration Software

acSELerator QuickSet SEL-5030 Software

QuickSet is a tool for engineers and technicians to quickly and easily configure, commission, and manage power system devices. QuickSet includes a Graphical Logic Editor and a device template tool to reduce configuration time and streamline deployment.

Learn more and download on the QuickSet software page.

SEL-5037 Grid Configurator Software

SEL Grid Configurator is a no-charge software tool for engineers and technicians to create, manage, and deploy settings for SEL power system devices.

Learn more and download on the Grid Configurator software page.

acSELerator Architect SEL-5032 Software

Architect allows users to configure and document IEC 61850 systems that include GOOSE, Sampled Values (SV), or Manufacturing Message Specification (MMS) communications. Architect automatically compares SCL files with IEC 61850 requirements to ensure standard compliance.

Learn more and download on the Architect software page.

Automated Data Collection

SEL Data Management and Automation (DMA) Application Suite

Available on the Blueframe platform, DMA applications automatically collect, store, and manage device-specific information like oscillography, Sequence of Events (SOE) data, device settings, and property information. They also provide automated password rotation and streamlined device audits.

Learn more on the DMA software page.

Visualization and Analysis

SEL-5601-2 synchroWAVe Event Software

synchroWAVe Event helps engineers diagnose a protective relay’s behavior during a power system fault. It is a powerful and easy-to-use solution for displaying and analyzing SEL relay event reports and COMTRADE files.

Learn more and download on the synchroWAVe Event software page.