SEL-851

Feeder Protection Relay

The SEL-851 provides comprehensive feeder protection, monitoring, and control for utility and industrial applications in a compact device. Its arc-flash protection capabilities significantly reduce incident energy by sending a trip signal to a breaker in as fast as 1 ms. With 10 kHz sampling of currents and voltages, the SEL-851 allows you to gain better visibility of your system. The relay is configured with SEL Grid Configurator software, enabling the quick creation, management, and deployment of device settings.

Starting At

$1,120Protect Feeders and Equipment—The SEL-851 includes four current inputs and three optional voltage inputs for comprehensive current, voltage, and frequency protection. Protect low- and medium-voltage three-phase feeders with current unbalance, over/underfrequency, breaker/contactor failure, phase, negative-sequence, and neutral instantaneous/time-overcurrent elements along with autoreclosing functionality. The voltage input option provides voltage, directional power, loss-of-potential, and power factor elements.

Increase Safety With Arc-Flash Mitigation—Improve safety and prevent equipment damage with the relay’s four optional arc-flash detection (AFD) inputs. The SEL-851 combines light-sensing technology and high-speed overcurrent protection to detect arc-flash events in as fast as 1 ms.

Improve System Visibility—With 10 kHz sampling of currents and voltages, the SEL-851 allows you to gain better visibility of your system. Identify problems, such as harmonics produced by switching or damaged cables, before they cause a significant interruption.

Increase System Reliability—Improve your system reliability by coordinating the SEL-851 and its reclosing control functionality with downstream reclosers for a complete restoration scheme.

Reduce Commissioning Time—Configure SEL-851 settings using SEL Grid Configurator software, a tool that increases efficiency and improves settings insights. It features a spreadsheet-style editor, powerful protection visualization, comprehensive reporting, custom filters, and multiple-device settings management.

Streamline Integration—The SEL-851 relay's Ethernet, serial, and USB-C ports and its various communications protocols, including Mirrored Bits communications and IEC 61850 Edition 2, make integrating it into your existing systems easy. Pick multiple sessions of Modbus TCP, Modbus serial, DNP3 LAN/WAN, or DNP3 serial for custom configuration of your applications.

Features

-

- 1

Large LCD for navigation, relay control, and diagnostics

- 2

Five LCD function keys for context-adjusted navigation

- 3

USB-C front-panel serial communications port for easy engineering access

- 4

Programmable tricolor target LEDs

- 5

Trip and Close breaker control pushbuttons

- 6

Local/Remote and multifunction Target Reset control pushbuttons

123456

-

-

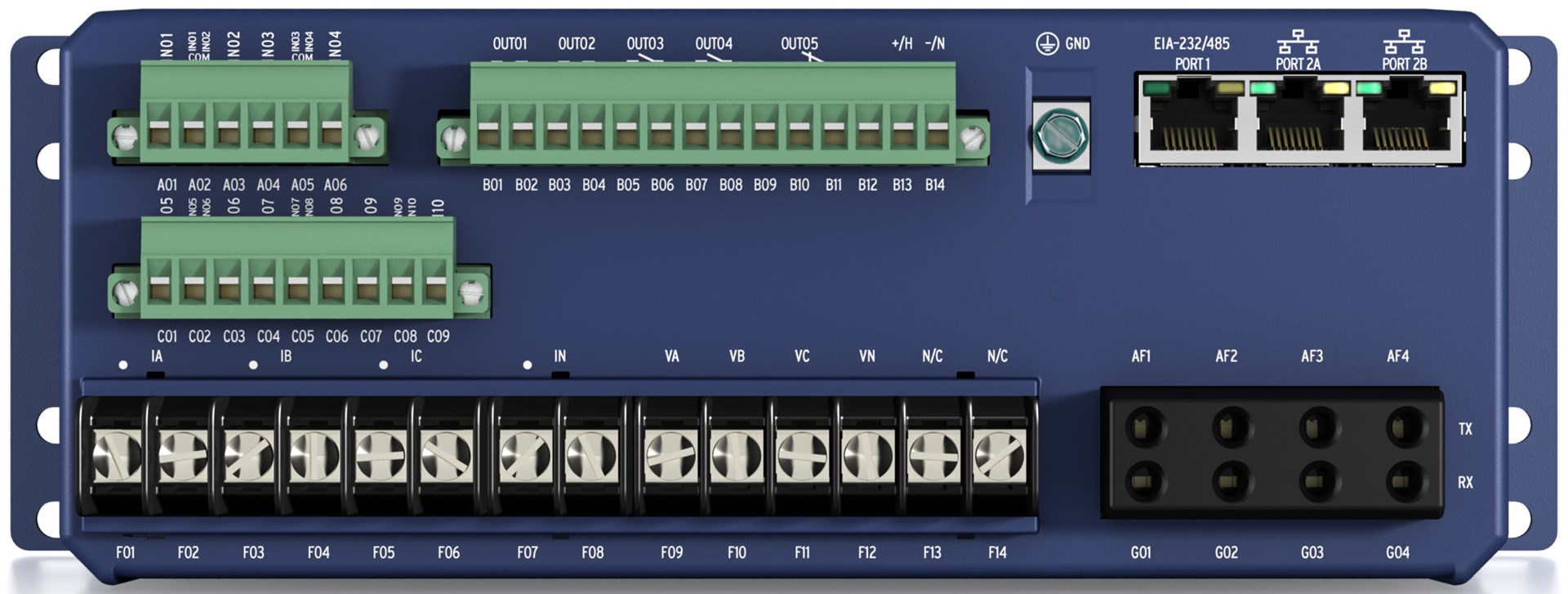

- 1

4 digital inputs

- 2

5 digital outputs (1 Form C, 2 Form A Standard, 2 Form A Hybrid)

- 3

Universal power supply (24–250 Vdc/110–240 Vac)

- 4

EIA-232/EIA-485 serial port with IRIG-B

- 5

Single or dual 10/100BASE-T Ethernet port(s) (optional)

- 6

6 additional digital inputs (optional)

- 7

4 current inputs

- 8

3 ac voltage inputs (300 Vac) (optional)

- 9

4 arc-flash inputs (optional)

123456789

-

Details

Feeder Protection Applications

The SEL-851 relay’s overcurrent functions protect power system circuits or devices, including lines, feeders, transformers, and capacitor banks. Over- and underfrequency and over- and undervoltage elements are well suited for applications at distributed generation sites. The relay’s directional power elements also make the SEL-851 suitable for utility or customer interface protection where customer generation is present. In addition, you can use the relay’s powerful SELogic control equations to provide custom protection and control applications.

Simplified Design

The SEL-851 is built with high-reliability hardware and comes with a universal power supply, setting-selectable universal current inputs (1 A/5 A), and optional software-selectable binary inputs (24–250 Vac/Vdc). Its simplified design helps reduce expenses.

Fast, Deterministic Relay-to-Relay Communications

Achieve fast, deterministic relay-to-relay communications using fixed GOOSE messaging. It provides ease of programming and offers the flexibility of multidevice communication of digital and analog quantities at a fixed 4 ms rate.

Integrated Web Server

The built-in web server enables secure, remote access to the relay with password protection. You can download status reports or view metering and relay information remotely. You can also safely read, edit, save, and download relay settings. This helps minimize trips to the relay location, saving time and money. The web server also enables firmware upgrades.

Operator Controls

Increase operator safety during commissioning and testing using the Local/Remote pushbutton control on the relay’s front panel. Perform breaker control using the Trip and Close pushbutton controls.

Metering and Monitoring

The SEL-851 relay’s built-in metering function allows you to eliminate separately mounted metering devices. Analyze Sequential Events Recorder (SER) reports and oscillographic event reports for rapid commissioning, testing, and post-fault diagnostics.

Signal Profiling

Signal profile monitoring provides a periodic snapshot (selectable rate of every 5, 10, 15, 30, or 60 minutes) of as many as 16 selectable analog quantities. The relay maintains signal profile information in nonvolatile buffer memory, which can hold as many as 4,000 time-stamped entries.

Relay Management and Diagnostics

- The Data Management and Automation (DMA) Application Suite on the SEL Blueframe platform is designed to automatically collect, store, and manage device-specific information to simplify day-to-day management of your system of devices and to support compliance. The DMA Diagnostics application provides SEL-851 status updates and detailed logs that help you monitor the relay’s health and quickly identify communications issues.

- SEL-5601-2 synchroWAVe Event Software helps you diagnose a protective relay’s behavior during a power system fault. It is a powerful yet easy-to-use solution for displaying and analyzing SEL relay event reports and COMTRADE files.

Rugged Hardware

Trust the industry’s widest ambient operating temperature range, –40° to +85°C (–40° to +185°F). The plastic chassis SEL-851 withstands vibration, electrical surges, fast transients, and extreme temperatures, meeting stringent industry standards. A conformal-coating option for the printed circuit boards provides an additional barrier to airborne contaminants, such as hydrogen sulfide, chlorine, salt, and moisture.

- Simple feeder protection (currents only), including reclosing

- Retrofit for SEL-551 Overcurrent/Reclosing Relay

- Advanced feeder protection (currents only), including reclosing

- Arc-flash mitigation

- Advanced feeder protection, including reclosing

- Voltage protection

- Communication

- Advanced feeder protection, including reclosing

- Arc-flash mitigation

- Voltage protection

- Communication

The Firmware IDs for older versions of the firmware can typically be found in Appendix A of the instruction manual.

Instruction Manuals

Sales Resource Central access is required to view the content in this tab.

Sales Resource Central851 - Software Tab

Configuration

SEL-5037 Grid Configurator

Grid Configurator is a freely distributed software tool for engineers and technicians to create, manage, and deploy settings for SEL power system devices.

Learn more and download on the Grid Configurator software page.

acSELerator Architect SEL-5032 Software

Architect allows users to configure and document IEC 61850 systems that include GOOSE, Sampled Values (SV), or Manufacturing Message Specification (MMS) communications. Architect automatically compares SCL files with IEC 61850 requirements to ensure standard compliance.

Learn more and download on the Architect software page.

Automated Data Collection

SEL Data Management and Automation (DMA) Application Suite

Available on the Blueframe platform, DMA applications automatically collect, store, and manage device-specific information like oscillography, Sequence of Events (SOE) data, device settings, and property information as well as provide automated password rotation and streamlined device audits.

Learn more on the DMA software page.

Visualization & Analysis

SEL-5601-2 synchroWAVe Event Software

synchroWAVe Event helps engineers diagnose a protective relay’s behavior during a power system fault. It is a powerful and easy-to-use solution for displaying and analyzing SEL relay event reports and COMTRADE files.

Learn more and download on the synchroWAVe Event software page.

Product Certifications

.png?n=63845173465000)