SEL-710

Motor Protection Relay

SEL recommends selecting the SEL-710-5 Motor Protection Relay in place of the SEL-710. The SEL-710-5 offers additional protection and communications options, such as incipient fault detection, vibration monitoring, and EtherNet/IP. It is also available with a color touchscreen display.

SEL will continue to support and warranty the SEL-710.

Starting At

$3,560Enhanced Motor Protection—Protect low- or medium-voltage three-phase motors with an enhanced thermal model that includes locked rotor starts, time-between-starts, starts-per-hour, antibackspin timer, load loss, current unbalance, load jam/stalled rotor, breaker/contactor failure, frequency, and overcurrent elements, including phase, negative-sequence, residual ground instantaneous, and inverse-time elements. Implement load control, star-delta starting, forward/reverse start control, and two-speed control. Use the SEL-710 with optional voltage and differential current inputs to include rotor slip calculation, differential overcurrent (87M), undervoltage, overvoltage, underpower, reactive power, phase reversal, power factor, and loss-of-potential protection.

RTD and PTC-Based Thermal Protection—Connect as many as ten resistance temperature detectors (RTDs) directly to the relay’s optional RTD input card to monitor stator winding, bearing, ambient, or other motor operating temperatures. Free up space for other relay options by using the external SEL-2600 RTD Module to collect up to 12 unique operating temperatures and to send those temperatures back to the relay over a communications link. RTD alarm and trip thresholds provide flexible backup protection and can also be used to bias the thermal model or to form a voting scheme to confirm mitigation decisions. Select the optional positive temperature coefficient (PTC) thermistor over-temperature input when thermistors are used as thermal backup measurement devices.

Reliable Protection in Harsh Environments—The SEL-710 operates in extreme conditions, with an operating temperature of –40° to +85°C (–40° to +185°F), and it is designed and tested to exceed applicable standards, including vibration, electromagnetic compatibility, and adverse environmental conditions. In addition, the SEL-710 is ATEX- and Underwriters Laboratories (UL) Class I, Division 2-certified for use in hazardous and potentially explosive environments.

Overcurrent Protection—Provide backup overcurrent protection on motor feeders with inverse-time and instantaneous overcurrent elements. The SEL-710 provides complete overcurrent protection, including phase, negative sequence, residual, and neutral overcurrent elements.

Metering and Monitoring—Metered quantities include phase voltages and currents; sequence voltages and currents; power, frequency, and energy; and maximum/minimum logging of selected quantities. The relay stores as many as 19 of the most recent 64-cycle event reports or 77 of the most recent 15-cycle event reports in nonvolatile memory. The relay also monitors and alarms when measured conditions are beyond allowable thresholds. For example, circuit breakers experience mechanical and electrical wear every time they operate. With each breaker operation, the relay integrates measured currents and increments the breaker operation counter. When the result of this integration exceeds the breaker wear curve threshold, the relay alarms via output contact, communications port, or front-panel display. This kind of information allows timely and economical scheduling of breaker maintenance.

Integration and Automation—Select from up to nine communications protocols, as many as four independently operated serial ports, copper or fiber Ethernet ports (single or dual), powerful relay logic, and programmable front-panel options to integrate the SEL-710 into high-performance systems of protection, automation, and control.

Features

-

- 1

Use default messages, or program up to 32 custom display labels

- 2

Large 2 × 16 character LCD

- 3

Front-panel LEDs can be programmed to indicate custom alarms

- 4

User-configurable label kit included with the relay

- 5

Use default pushbuttons, or program your own pushbutton actions and labels

12345

-

-

- 1

Power supply options include 24–48 Vdc, 110–250 Vdc, and 110–240 Vac

- 2

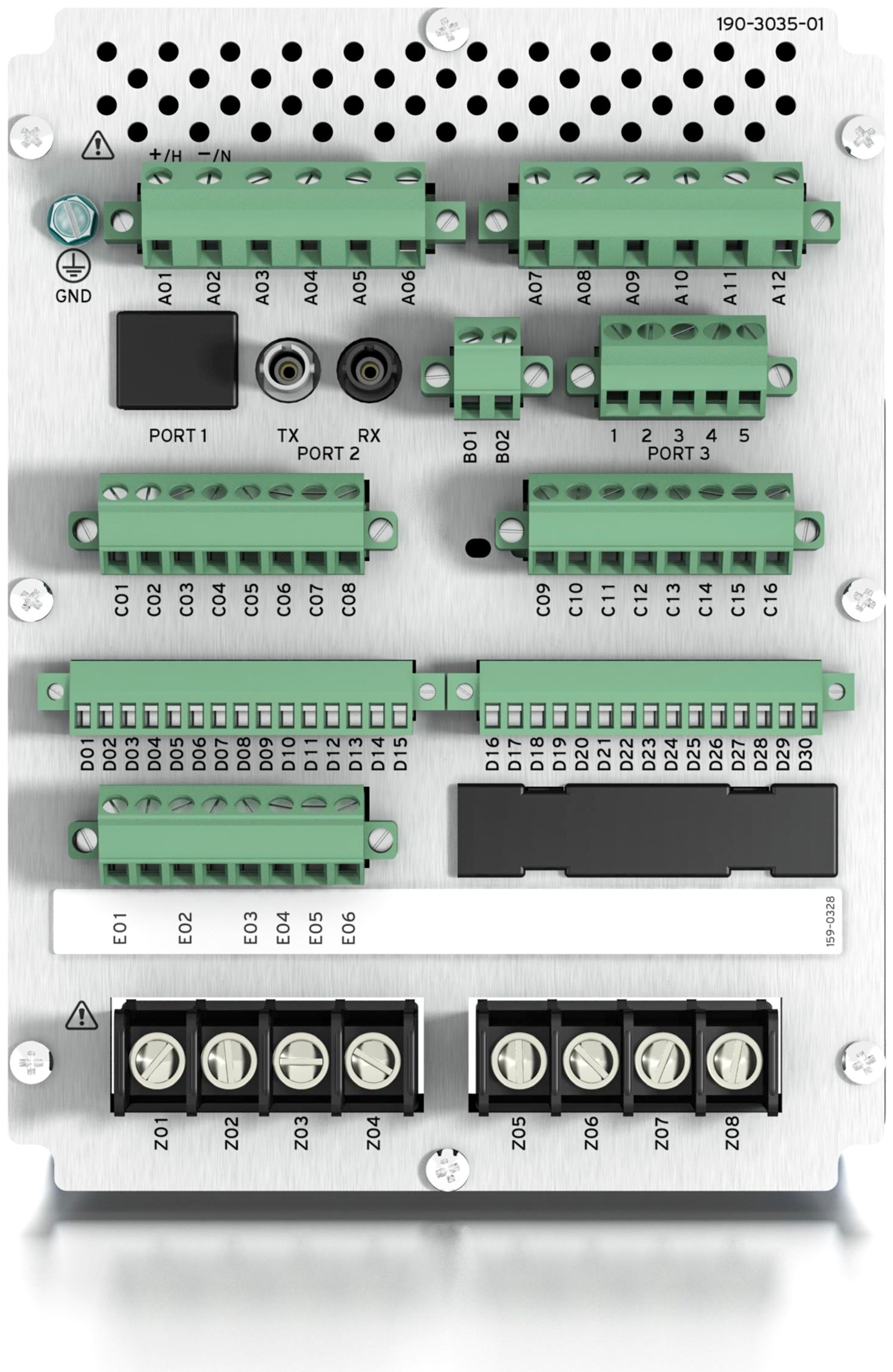

Port 1 concurrently supports two Modbus TCP, two FTP, two Telnet,one SNTP, and six IEC 61850 sessions

- 3

Optional Ethernet, Modbus® TCP, and/or IEC 61850

- 4

IRIG-B or PTC input

- 5

Mirrored Bits® communications

- 6

Positions for optional I/O cards shown with 4 DI/4 DO card, RTD input card, and voltage and current differential input card

- 7

Positions for optional I/O cards shown with 4 DI/4 DO card, RTD input card, and voltage and current differential input card

- 8

CT inputs include a sensitive neutral option

12345678

-

Details

Optimize Start Times

The SEL-710 calculates thermal energy in the motor to determine maximum safe start times, with full motor protection. Accurate temperature tracking also minimizes the time needed between starts.

Convenient Controls

Use the four programmable pushbuttons on the front panel for quick personalized control, with factory default start and stop functions.

Advanced Protection

The SEL-710 provides protection for overcurrent, thermal overload, undercurrent, current unbalance, current differential, phase loss, ground fault, and over- or underfrequency, and much more.

Easy Communications

Choose from single or dual, copper or fiber-optic Ethernet as well as Modbus TCP, IEC 61850, Modbus Serial, EIA-232, EIA-485, Telnet, and File Transfer Protocol (FTP) communications. Pick one or multiple connections, including multiple Modbus sessions for custom configuration of your application.

Rugged Design

Trust the industry’s widest ambient operating temperature range, –40° to +85°C (–40° to +185°F). The SEL-710 withstands vibration, electrical surges, fast transients, and extreme temperatures, meeting stringent industry standards. A conformal-coating option for the printed circuit boards provides an additional barrier to airborne contaminants, such as hydrogen sulfide, chlorine, salt, and moisture. In addition, the SEL-710 is ATEX- and Underwriters Laboratories (UL) Class I, Division 2-certified for use in hazardous and potentially explosive environments.

- Low- or medium-voltage three-phase motor protection

- Electromechanical relay retrofit

- Advanced motor protection with differential overcurrent elements

- Conformally coated circuit boards for harsh environmental applications

Minimum Software Version

| Product | Revision | Z Number | acSELerator QuickSet Version | SEL Grid Configurator Version |

|---|---|---|---|---|

| SEL-710 | R411-V0 | 007 | 6.6.0.0 | |

| Please contact Application Engineer for firmware related to your hardware platform. The current revision does not apply to all hardware. | ||||

Latest Firmware Versions

There are no firmware versions available for this product.

| Product | Revision | Firmware ID | Date Available | Serial Number |

|---|---|---|---|---|

| SEL-710 | R412-V3 | SEL-710-R412-V3-Z008004-D20260130 | 2/17/26 | ~3260480001 |

The Firmware IDs for older versions of the firmware can typically be found in Appendix A of the instruction manual.

Minimum Software Version

| Product | Revision | Z Number | acSELerator QuickSet Version | SEL Grid Configurator Version |

|---|---|---|---|---|

| SEL-710 | R411-V0 | 007 | 6.6.0.0 | |

| Please contact Application Engineer for firmware related to your hardware platform. The current revision does not apply to all hardware. | ||||

Instruction Manuals

710 - Software Tab

Configuration

acSELerator QuickSet SEL-5030 Software

QuickSet is a tool for engineers and technicians to quickly and easily configure, commission, and manage power system devices. QuickSet includes a Graphical Logic Editor and a device template tool to reduce configuration time and streamline deployment.

Learn more and download on the QuickSet software page.

acSELerator Architect SEL-5032 Software

Architect allows users to configure and document IEC 61850 systems that include GOOSE, Sampled Values (SV), or Manufacturing Message Specification (MMS) communications. Architect automatically compares SCL files with IEC 61850 requirements to ensure standard compliance.

Learn more and download on the Architect software page.

Automated Data Collection

SEL Device Management and Automation (DMA) Application Suite

Available on the Blueframe platform, DMA applications automatically collect, store, and manage device-specific information like oscillography, Sequence of Events (SOE) data, device settings, and property information. They also provide automated password rotation and streamlined device audits.

Learn more on the DMA software page.

Visualization and Analysis

SEL-5601-2 Synchrowave Event Software

Synchrowave Event helps engineers diagnose a protective relay’s behavior during a power system fault. It is a powerful and easy-to-use solution for displaying and analyzing SEL relay event reports and COMTRADE files.

Learn more and download on the Synchrowave Event software page.