SEL-787-2/-3/-4

Transformer Protection Relay

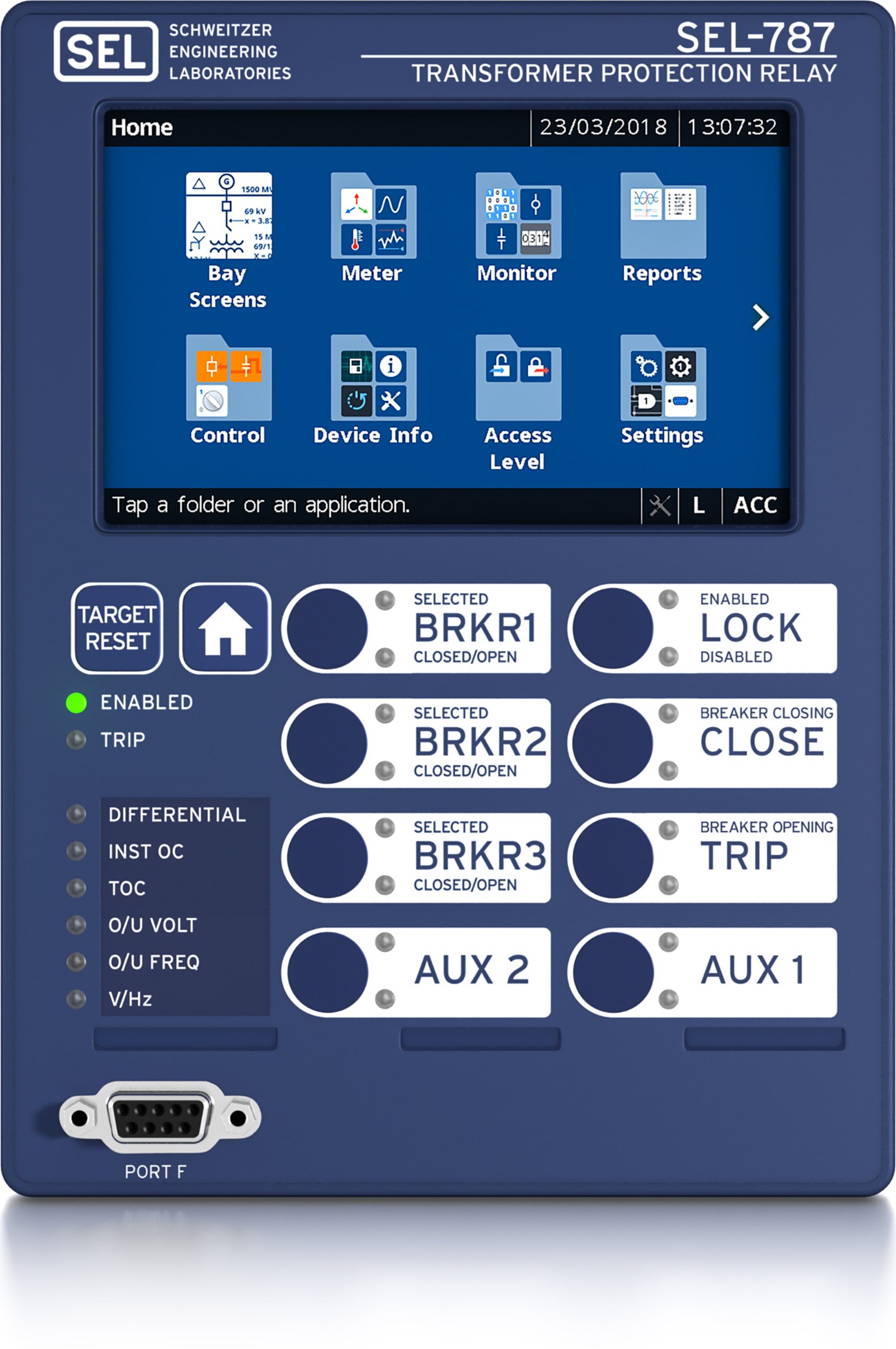

Protect and monitor most two-, three-, and four-winding transformers with the versatile SEL-787 platform. It provides advanced automation and flexibility, asset management data, and easy retrofitting of most electromechanical relays. The 5-inch, 800 × 480 color touchscreen display option allows you to directly set, monitor, and control your system, including up to five two- or three-position disconnect switches.

The SEL-787-2E/-21/-2X models offer two-winding differential protection, and the SEL-787-3E/-3S models offer three-winding differential protection. Select the SEL-787-4X for current-based four-winding differential protection.

Starting At

$3,880Multiwinding Protection—Select the SEL-787 for standard dual-slope differential protection with harmonic blocking and restraint for most two-, three-, and four-winding transformers. The SEL-787 offers as many as three independent restricted earth fault (REF) elements for sensitive ground-fault detection in grounded-wye transformers. The relay also comes with a variety of overcurrent elements for backup protection, including phase, negative-sequence, residual-ground, and neutral-ground elements. Breaker failure protection for as many as four 3-pole breakers is also standard.

Frequency Tracking—Choose the SEL-787 for generator step-up and variable-frequency applications. The relay has voltage inputs to provide volts/hertz protection with frequency tracking from 20 to 70 Hz. Over-/underfrequency and over-/undervoltage elements allow you to implement load shedding and other control schemes with the relay.

Synchronism Check/Station DC Battery Monitor—Program the VS/VBAT voltage channel in the SEL-787-3S to perform a synchronism check across a circuit breaker or to monitor dc voltage levels of the substation battery.

Through-Fault Monitoring and Protection—Measure accumulated through-fault levels with the transformer through-fault monitor. Additionally, the optional 4–20 mA or resistance temperature detector (RTD) thermal inputs can monitor ambient, load tap changer (LTC) tank, and transformer oil temperatures.

Reliable Protection in Harsh Environments—The SEL-787 operates in extreme conditions, with an operating temperature of –40° to +85°C (–40° to +185°F), and it is designed and tested to exceed applicable standards, including vibration, electromagnetic compatibility, and adverse environmental conditions. In addition, the SEL-787 is ATEX- and Underwriters Laboratories (UL) Class I, Division 2-certified for use in hazardous and potentially explosive environments.

Metering and Reporting—Eliminate separately mounted metering devices with the built-in metering functions. You can analyze Sequential Events Recorder (SER) reports and oscillographic event reports for rapid commissioning, testing, and post-fault diagnostics. You can also transfer event files in COMTRADE and CEV formats and transfer CID files, settings, and reports. The unsolicited SER protocol allows station-wide collection of binary SER messages.

Local/Remote Operator Controls—Employ eight programmable front-panel pushbuttons, each with two programmable tricolor LEDs, for a wide variety of uses, including easy trip/close control and status indication for all the breakers. With the operator control interface pushbuttons, you can easily implement local and remote operator control schemes using 32 local and 32 remote control bits. SELogic control equations and slide-in, configurable front-panel labels allow you to change the function and identification of target LEDs and operator control pushbuttons and LEDs.

Integration and Automation—Select from a wide array of communications protocols and media to support all your integration and automation solutions. You can quickly integrate the SEL-787 into serial- or Ethernet-based communications schemes with IEC 61850 Edition 2, IEC 60870-5-103, Rapid Spanning Tree Protocol (RSTP), the IEC 62439 Parallel Redundancy Protocol (PRP), Ethernet/IP, IEEE 1588 Precision Time Protocol (PTP), Mirrored Bits communications, Modbus, DNP3, and other protocols. You can choose English or Spanish front panels, with optional Spanish language support in the PC software, ASCII ports, and HMI.

Features

- Front—LCD Version

- Front—Touchscreen Version

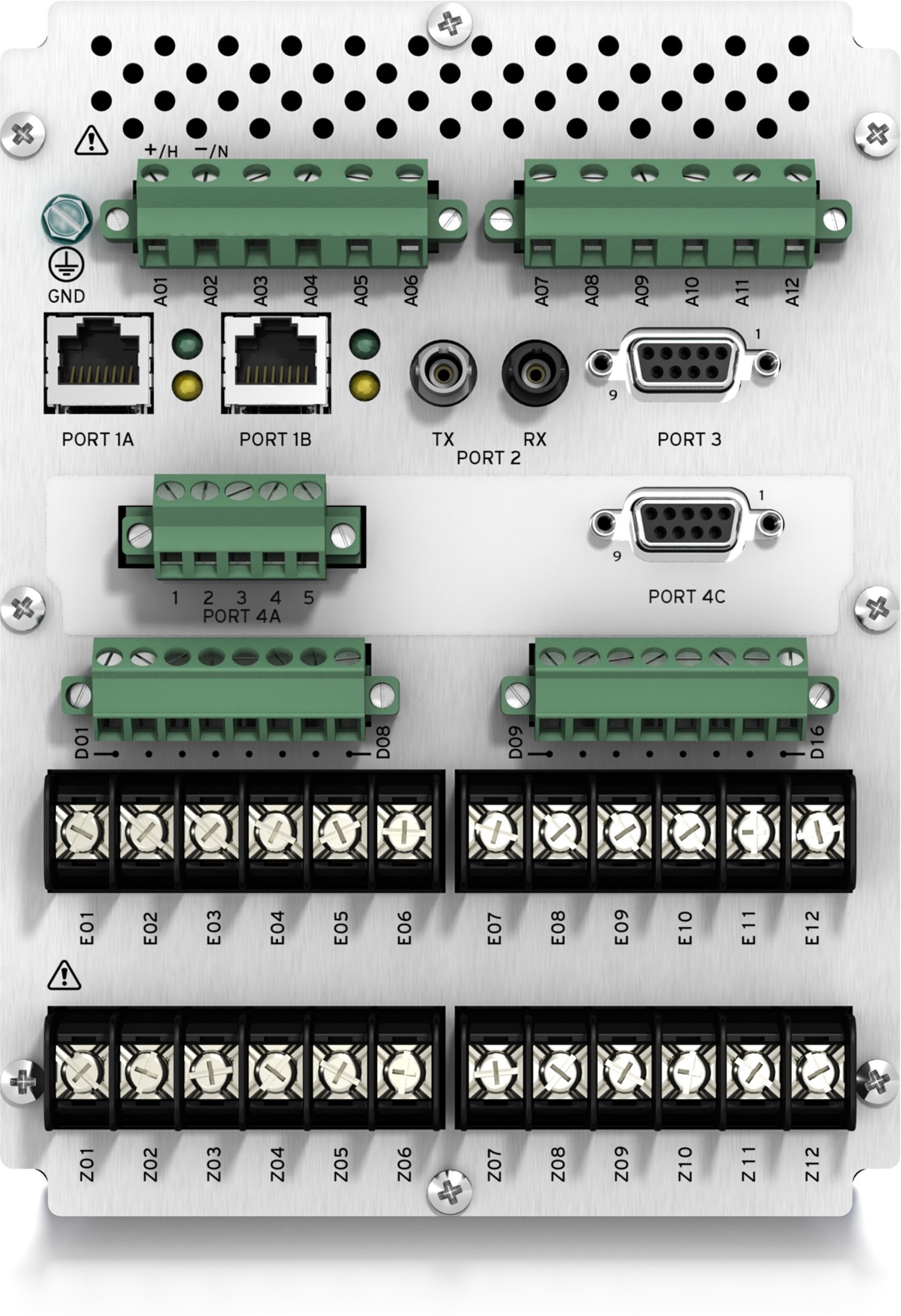

- Back

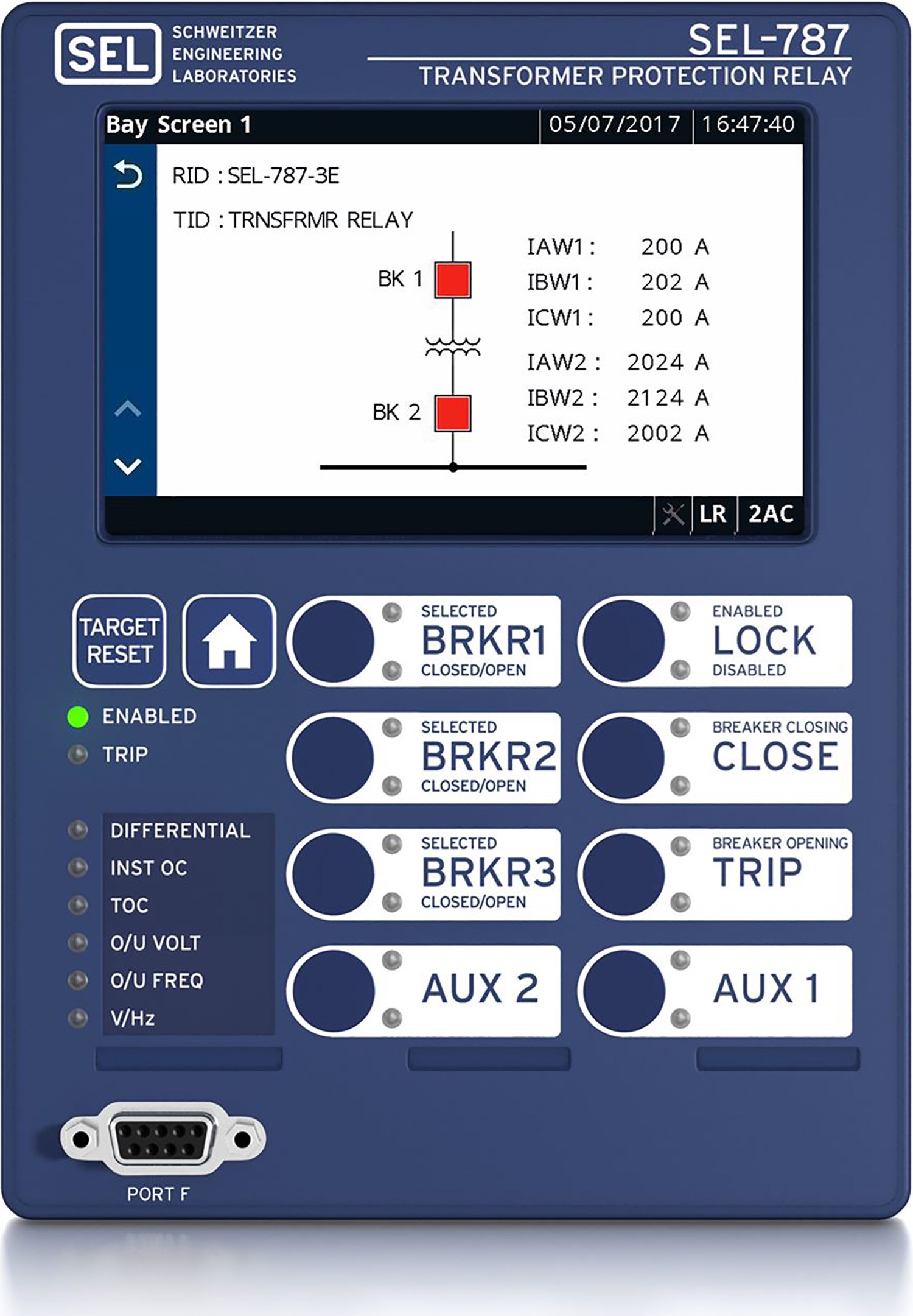

- Touchscreen—Bay Screen

- Touchscreen—Authentication

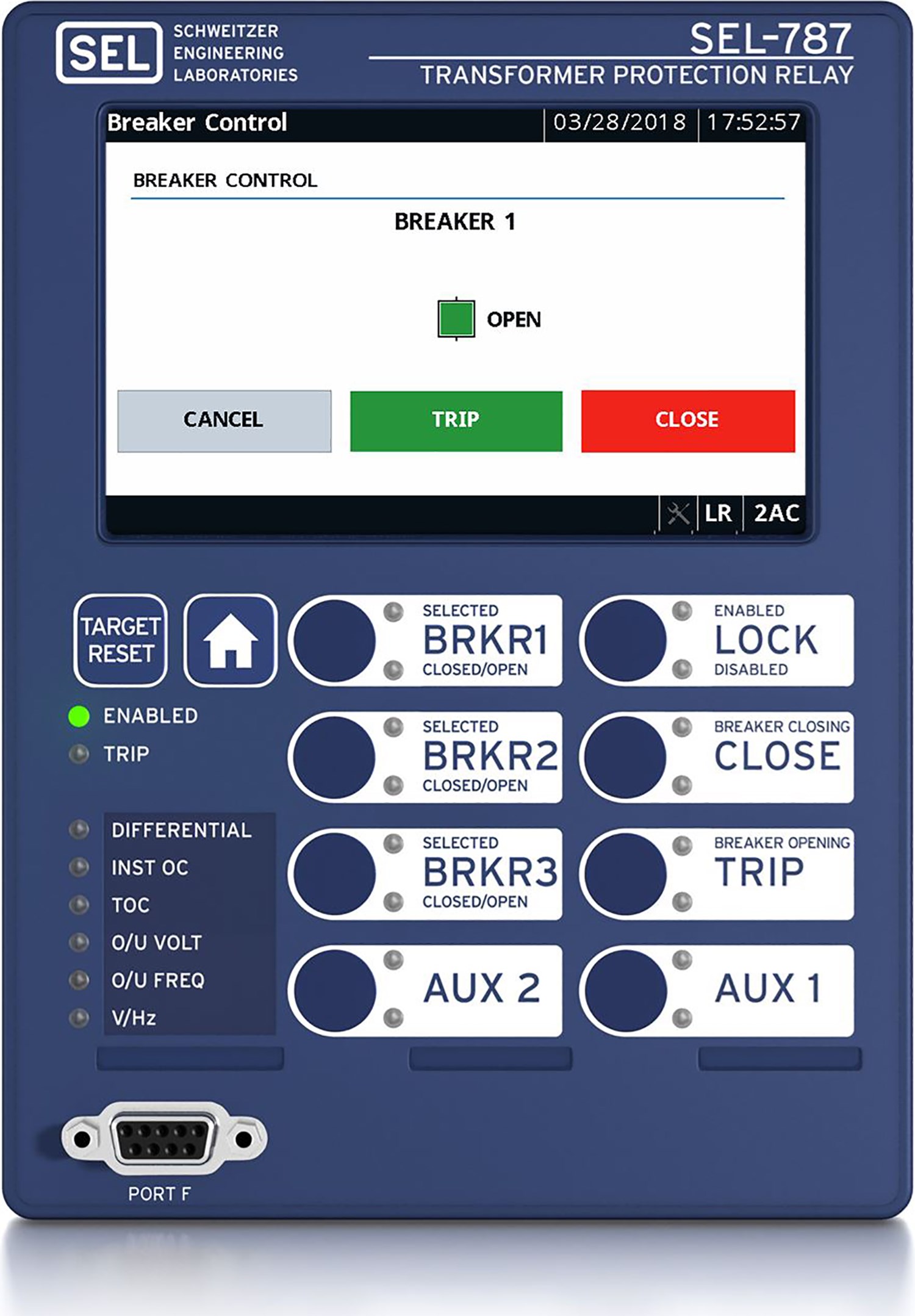

- Touchscreen—Breaker Control

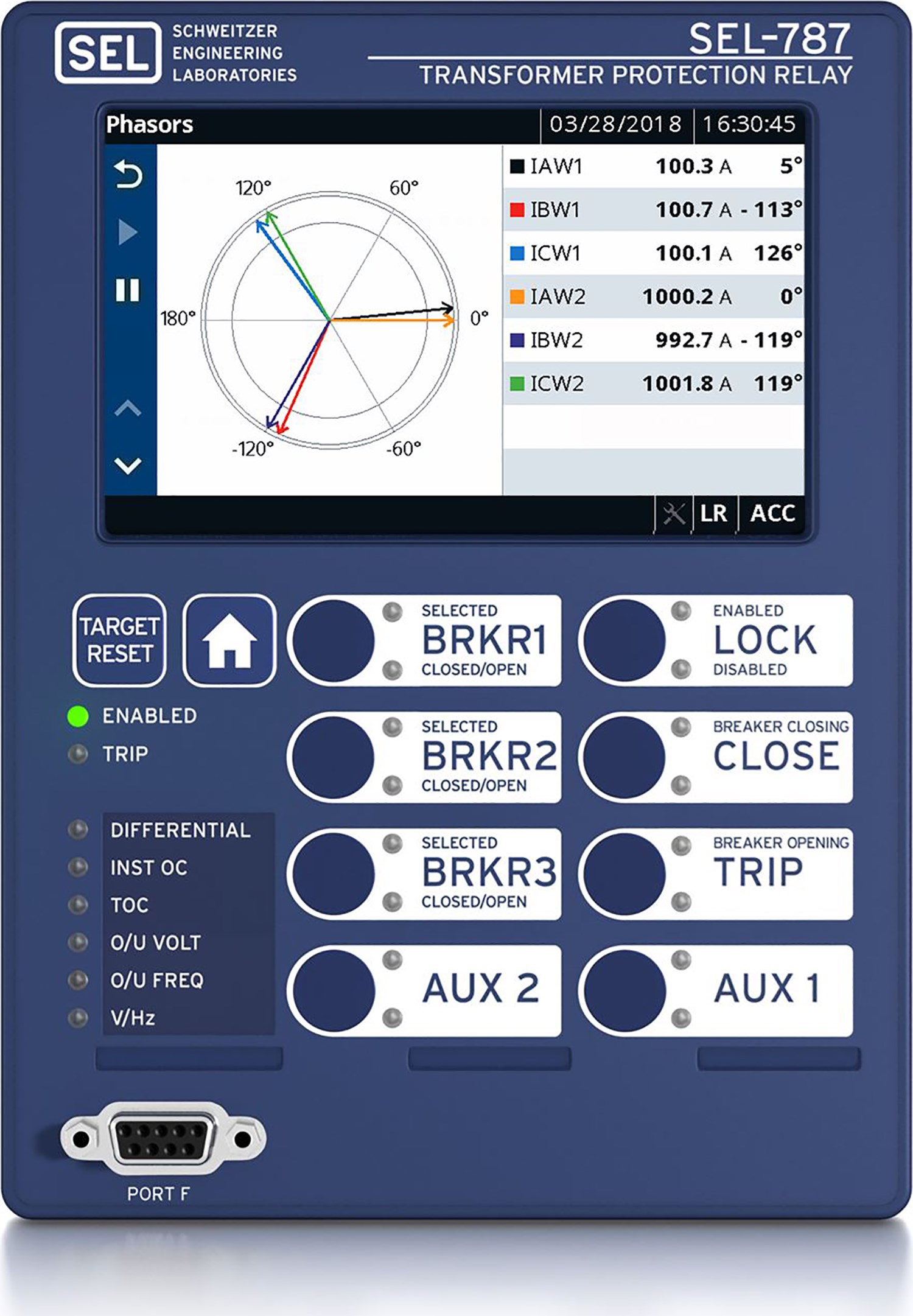

- Touchscreen—Phasors

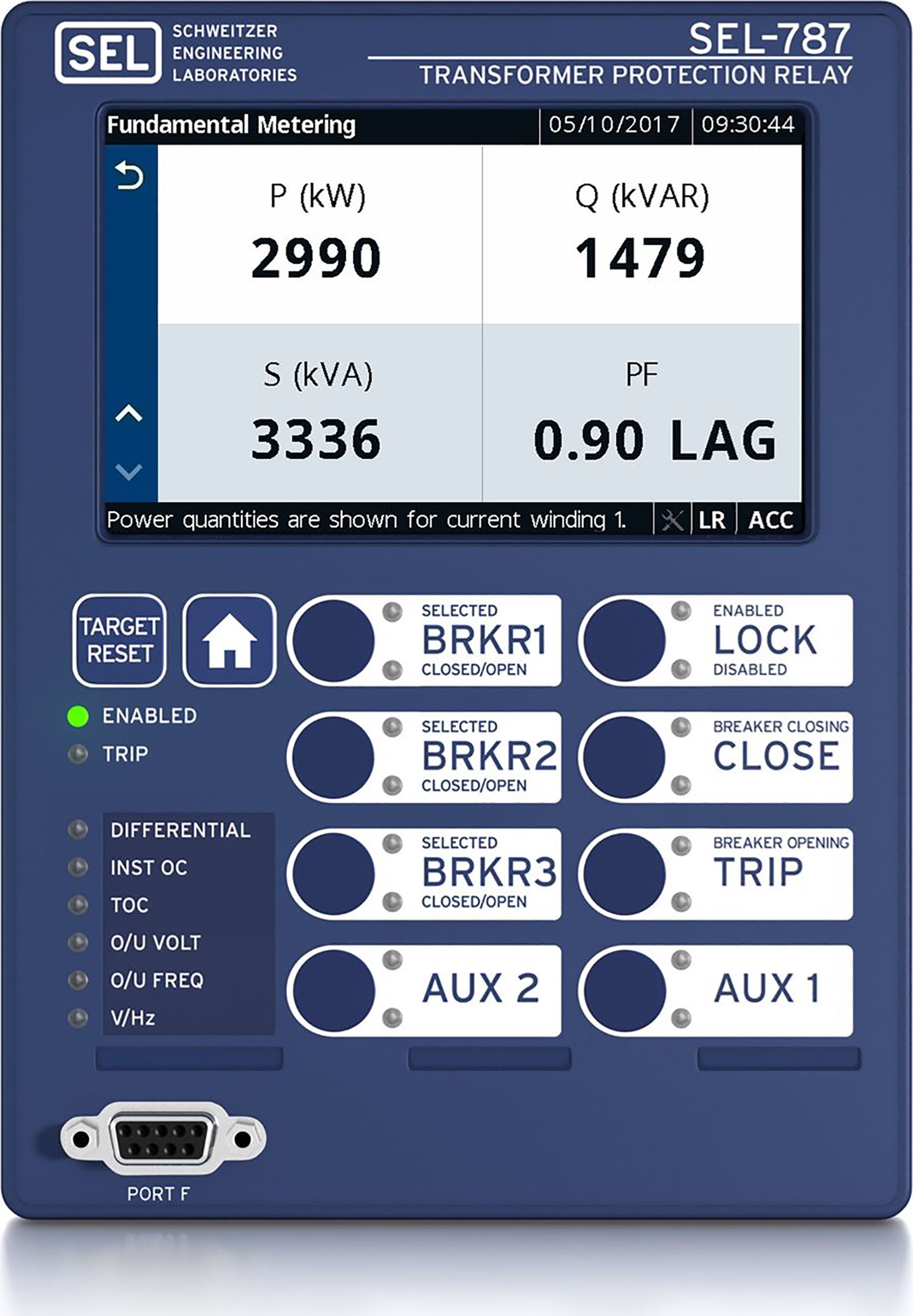

- Touchscreen—Fundamental Metering

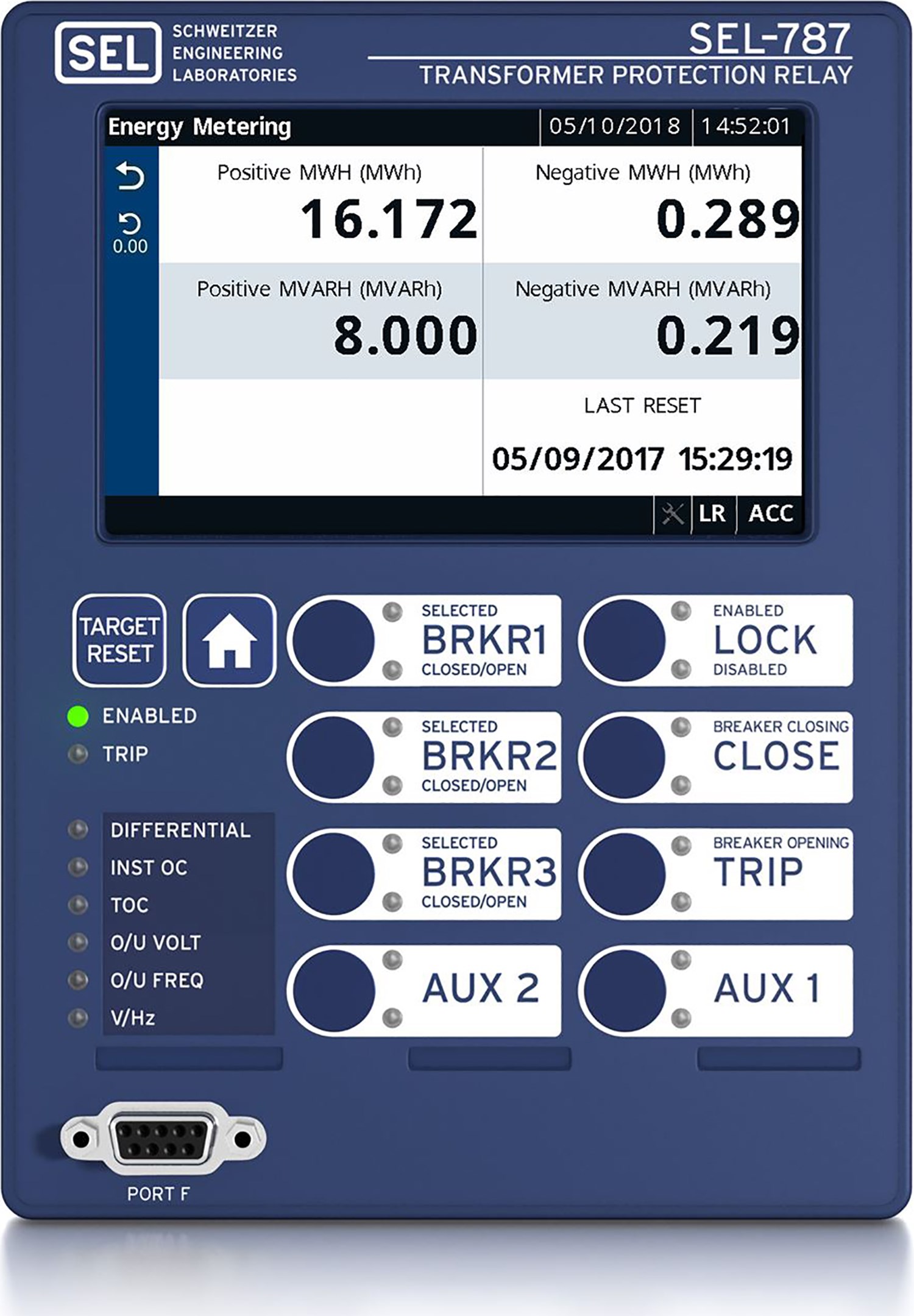

- Touchscreen—Energy

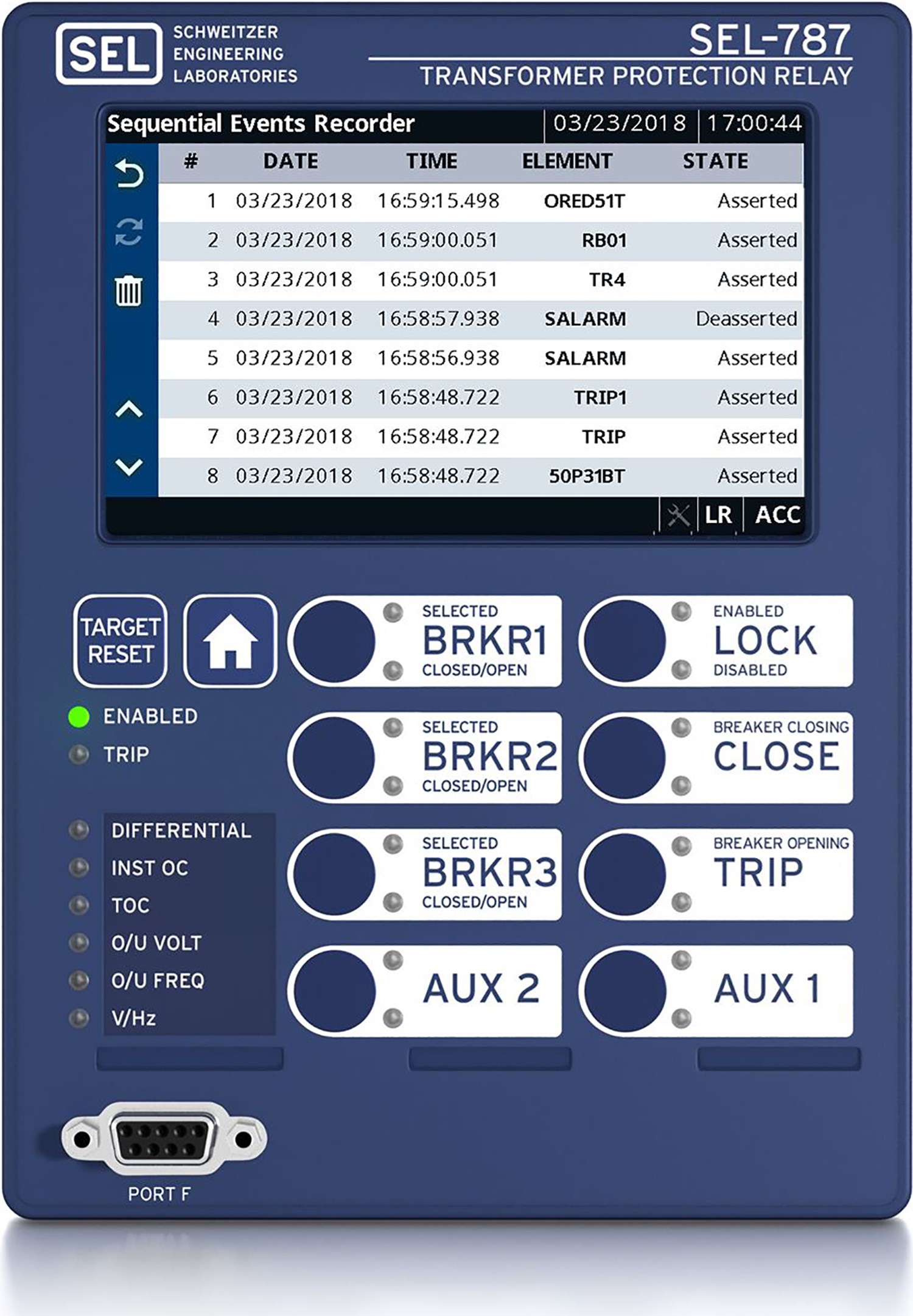

- Touchscreen—Sequential Events Recorder

-

- 1

Large 2 × 16 character LCD

- 2

Default messages or up to 32 customizable display labels notify personnel of power system events or the relay status

- 3

Programmable front-panel tricolor LEDs

- 4

Customizable pushbuttons and labels

- 5

User-configurable label kit

- 6

Two programmable tricolor LEDs per pushbutton

123456

-

-

- 1

The 5-inch, 800 × 480 color touchscreen display offers direct navigation via a capacitive touchscreen

- 2

Full keyboard facilitates easy adjustment of settings systems

- 3

Folders and applications provide quick access to bay screens, metering and monitoring data, reports, settings, and more

- 4

The home pushbutton allows you to easily return to the default home screen

1234

-

-

- 1

Power supply options include 110–250 Vdc/110–240 Vac or 24–48 Vdc

- 2

2 digital inputs (DI) and 3 digital outputs (DO)

- 3

A wide variety of communications protocols and media for flexibility to communicate with other devices and control systems

- 4

An integrated web server enables direct relay access for metering and monitoring data

- 5

EIA-232 serial port (P3) and fiber-optic EIA-232 serial port (P2) with IRIG-B input

- 6

Positions for optional I/O cards

- 7

Positions for current and voltage options

1234567

-

-

- 1

Bay Screens and Bay Control

Select from predefined bay screens, or configure as many as five custom bay screens using acSELerator® Bay Screen Builder SEL-5036 Software and acSELerator QuickSet® SEL-5030 Software. With the bay screen, you can control as many as 4 breakers, 16 two-position disconnects, and 2 three-position disconnects and can view analog and digital data in a contextual display.

To control a breaker, simply tap the Bay Screens application on the home screen and then the breaker you want to control.

1

-

-

- 1

Authentication

Enter your Level 2 password and tap Submit. The onscreen keyboard allows you to quickly and easily enter passwords.

1

-

-

- 1

Breaker Control

Tap Trip or Close to control the breaker. When asked to confirm the action before the operation is completed, choose Yes or No.

1

-

-

- 1

Meter Phasors

View a graphical and textual representation of the real-time voltages and currents in a power system during balanced and unbalanced conditions. By analyzing the phasors, you can determine power system conditions.

1

-

-

- 1

Meter Fundamentals

View the real, reactive, and apparent power of each hase in your system, and monitor the power factor information to determine if the phase current leads or lags the phase voltage.

1

-

-

- 1

Meter Energy

Display the real, reactive, and apparent energy metering quantities imported and exported in a system. Easily reset the values via the display, and record the time and date of reset.

1

-

-

- 1

Sequential Events Recorder

Easily review the time-stamped SER data, including whether or not the Relay Word bit asserted or deasserted, during root-cause analysis of an event.

1

-

Details

Two-, Three-, and Four-Winding Current Differential, Overcurrent, Voltage, and Breaker Failure Protection

Apply two-, three-, or four-winding dual-slope differential protection with phase, negative-sequence, residual, and neutral overcurrent elements for backup protection. You can set elements in SEL-787-3E/-3S models for voltage- and frequency-based protection. Breaker failure protection for as many as four three-pole breakers comes standard.

Security and Dependability

Provide maximum security during external faults and transformer magnetizing inrush conditions. The SEL-787 can detect internal faults quickly during energization or normal operating conditions by using combined harmonic-blocking and harmonic-restraint differential elements.

Transformer Monitoring

Set the SEL-787 to record and accumulate through-fault duty for use in SELogic control equations or manual monitoring. In addition, you can monitor ambient, LTC tank, and transformer oil temperatures with optional 4–20 mA analog inputs or RTD thermal inputs to extend the life of your transformer.

Operator Control

Use eight programmable front-panel pushbuttons, each with two programmable, tricolored LEDs, for a wide variety of applications, including easy trip-and-close control and status indications for a breaker. You can implement local and remote operator control schemes with 32 local and 32 remote control bits.

Optional Touchscreen Display

The easy-to-use touchscreen interface provides a one-line mimic display for bay control and monitoring. View metered quantities, phasor diagrams, relay settings, event summaries, target statuses, Sequential Events Recorder (SER) data, and more. Extensive testing shows that the robust capacitive touchscreen display meets or exceeds industry standards as well as SEL quality and reliability requirements.

IEC 61850 Test Mode

Test 61850 system components in energized substations without fear of operating control output contacts.

Webserver Access

The built-in webserver enables secure, remote access to the relay with password protection. Download status reports or view metering and relay information remotely. This helps minimize trips to the relay location, which saves time and money.

Accelerate Firmware Downloads

Simplify maintenance by downloading relay firmware via the Ethernet port. This also enables you to access and update all of your network relays simultaneously.

Metering and Reporting

Eliminate separately mounted metering devices with built-in metering functions. You can analyze SER reports and oscillographic event reports in COMTRADE and CEV formats to analyze post-fault diagnostics and for rapid commissioning and testing. You can retrieve COMTRADE files via Ethernet FTP or IEC 61850 MMS, and the unsolicited SER protocol allows station-wide collection of binary SER messages. SEL-787 metered quantities include harmonics, power, frequency, and energy; phase voltages and currents; neutral currents; sequence voltages and currents; and maximum/minimum logging of selected quantities.

Rugged Design

Trust the industry’s widest ambient operating temperature range, –40° to +85°C (–40° to +185°F). The SEL-787 withstands vibration, electrical surges, fast transients, and extreme temperatures, meeting stringent industry standards. A conformal-coating option for the printed circuit boards provides an additional barrier to airborne contaminants, such as hydrogen sulfide, chlorine, salt, and moisture. In addition, the SEL-787 is ATEX- and Underwriters Laboratories (UL) Class I, Division 2-certified for use in hazardous and potentially explosive environments.

- Two-terminal transformer protection

- Restricted earth fault (REF) elements for sensitive ground fault detection

- Dual Ethernet ports for backup failover communications channel

- Comprehensive protocols, including IEC 61850, for easy integration

- Three-terminal transformer protection relay

- REF elements for sensitive ground fault detection

- Dual Ethernet ports for backup fail-over communications channel

- Comprehensive protocols, including IEC 61850 and DNP3, for easy integration

- Three-terminal transformer protection

- REF elements for sensitive ground fault detection

- Dual Ethernet ports for backup failover communications channel

- Comprehensive protocols, including IEC 61850, for easy integration

- Four-terminal transformer protection

- REF elements for sensitive ground fault detection

- Dual Ethernet ports for backup failover communications channel

- Comprehensive protocols, including IEC 61850, for easy integration

Minimum Software Version

Latest Firmware Versions

There are no firmware versions available for this product.

| Product | Revision | Firmware ID | Date Available | Serial Number |

|---|

The Firmware IDs for older versions of the firmware can typically be found in Appendix A of the instruction manual.

Minimum Software Version

Instruction Manuals

Sales Resource Central access is required to view the content in this tab.

Sales Resource Central787-2 - Software Tab

Configuration

acSELerator QuickSet SEL-5030 Software

QuickSet is a tool for engineers and technicians to quickly and easily configure, commission, and manage power system devices. QuickSet includes a Graphical Logic Editor and a device template tool to reduce configuration time and streamline deployment.

Learn more and download on the QuickSet software page.

acSELerator Architect SEL-5032 Software

Architect allows users to configure and document IEC 61850 systems that include GOOSE, Sampled Values (SV), or Manufacturing Message Specification (MMS) communications. Architect automatically compares SCL files with IEC 61850 requirements to ensure standard compliance.

Learn more and download on the Architect software page.

Automated Data Collection

SEL Data Management and Automation (DMA) Application Suite

Available on the Blueframe platform, DMA applications automatically collect, store, and manage device-specific information like oscillography, Sequence of Events (SOE) data, device settings, and property information. They also provide automated password rotation and streamlined device audits.

Learn more on the DMA software page.

Visualization and Analysis

SEL-5601-2 synchroWAVe Event Software

synchroWAVe Event helps engineers diagnose a protective relay’s behavior during a power system fault. It is a powerful and easy-to-use solution for displaying and analyzing SEL relay event reports and COMTRADE files.

Learn more and download on the synchroWAVe Event software page.