.png?n=63901600916000&preset=size-col-8&bp=lg)

SEL-2414

Transformer Automation Controller (TAC)

The SEL-2414 is a thermal and load tap changer (LTC) controller in one versatile, rugged device. It supports a full range of monitoring and control solutions, including LTC control, transformer paralleling schemes, and cooling bank optimization. Customize the device from a wide range of I/O cards and communications protocols to fit your needs. Designed, manufactured, and tested in the United States, every SEL-2414 includes a ten-year, worldwide warranty and comes with no-cost technical support.

Starting At

$1,660Regulate Voltage—Optimize transformer performance for power flow directions, seasonal variations, and demand fluctuations. Select from time-based or inverse-time-based tap delays to control raise and lower commands. Maintain voltage stability and prevent equipment damage by using the tap-change limit and alarm capabilities.

Prevent Transformer Overloading—Balance load across paralleled transformers using leader/follower or current angle schemes, including a configurable intertap delay. Preconfigured settings make it easy to set up Ethernet-based paralleling schemes. Operators can adjust paralleling behavior, including switching the lead controller in paralleling schemes.

Optimize Thermal Management—Operate cooling stages by using transformer hotspot temperature calculations. Exercise transformer cooling banks to eliminate unexpected maintenance events during critical load conditions. Alternate fan banks to balance cooling duty cycles and increase the life of cooling systems.

Monitor Transformer Life—Track transformer loss of life using the IEEE C57.91-2011 or IEC 60076-7:2018 thermal model for various winding configurations (including three sets of single-phase transformers). Directly measure ambient and top oil temperatures with a resistance temperature detector (RTD) or thermocouple input card. Monitor both digital and analog sensor outputs, such as oil level and pressure. In addition, through-fault monitoring tracks events that cause mechanical and thermal stress to transformers.

Increase System Awareness—Capture a broad range of data, including triggered oscillography, LTC event records, thermal records, and custom records. The reports allow you to accurately trend transformer load and correlate the data with system parameters. The controller provides basic metering, such as voltage and current measurements, maximum/minimum values, and demand and peak-demand values. Use the data to enhance asset management and plan for future expansion.

Modernize Your Transformer Controller—Specify the SEL-2414 with a new transformer installation, retrofit other OEM LTC controllers by using adapter plates and direct-replacement assemblies, or upgrade an existing controller by adding an LTC controller license. For a complete turnkey solution, use the full engineering product support offered by SEL Engineering Services.

Features

-

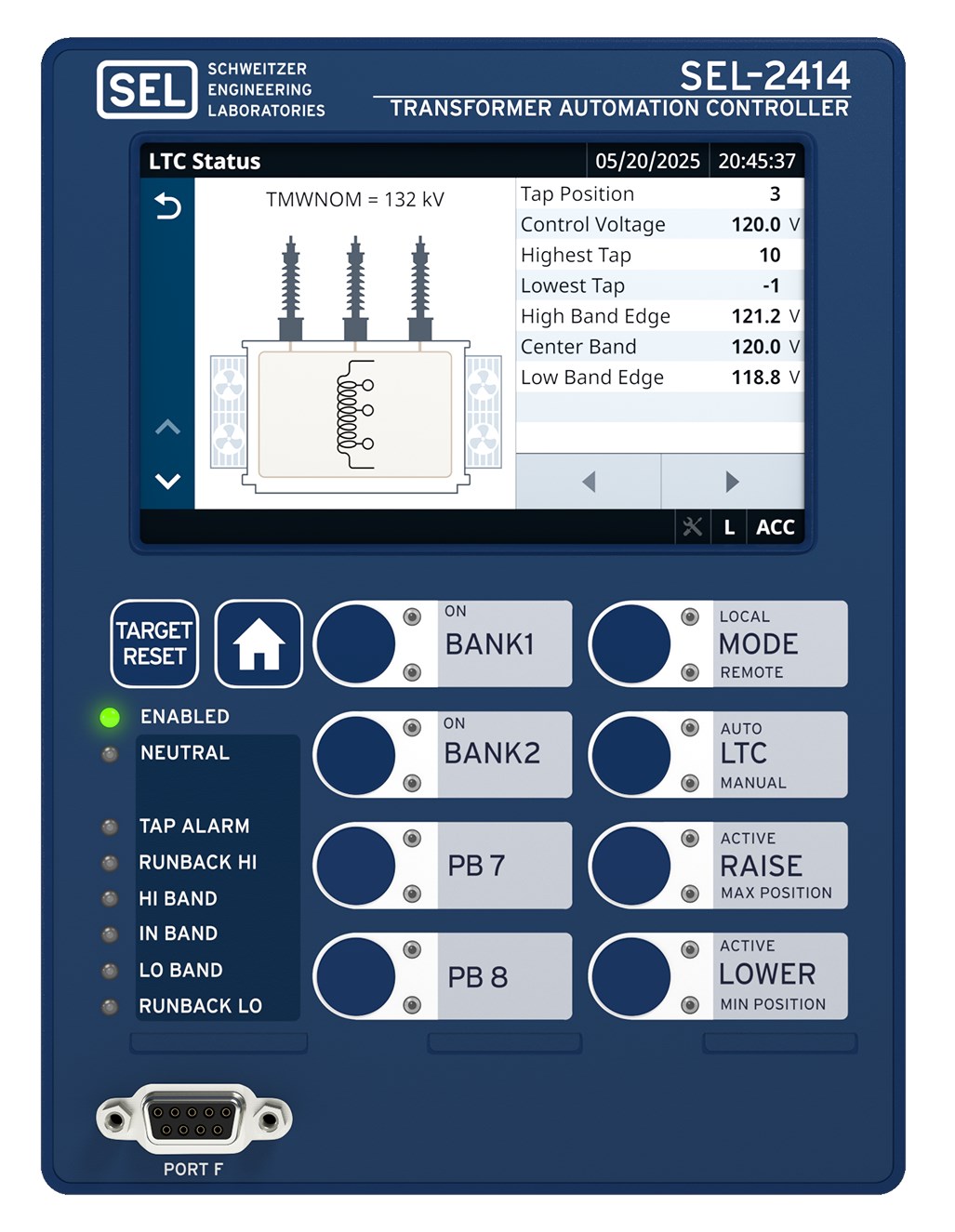

- 1

The 5-inch color display with a resolution of 800 × 480 pixels offers direct navigation via a capacitive touchscreen.

- 2

Display alarms, Sequential Events Recorder (SER) data, loss-of-life status, and LTC status are visible on the touchscreen.

- 3

Adjust controller settings by using the onscreen keyboard.

- 4

Execute commands by using programmable pushbuttons.

- 5

Alert onsite staff to device conditions by using programmable LEDs.

- 6

Install in harsh environments. The color touchscreen has an operating temperature range of –20° to 70°C (–4° to +158°F).

123456

-

-

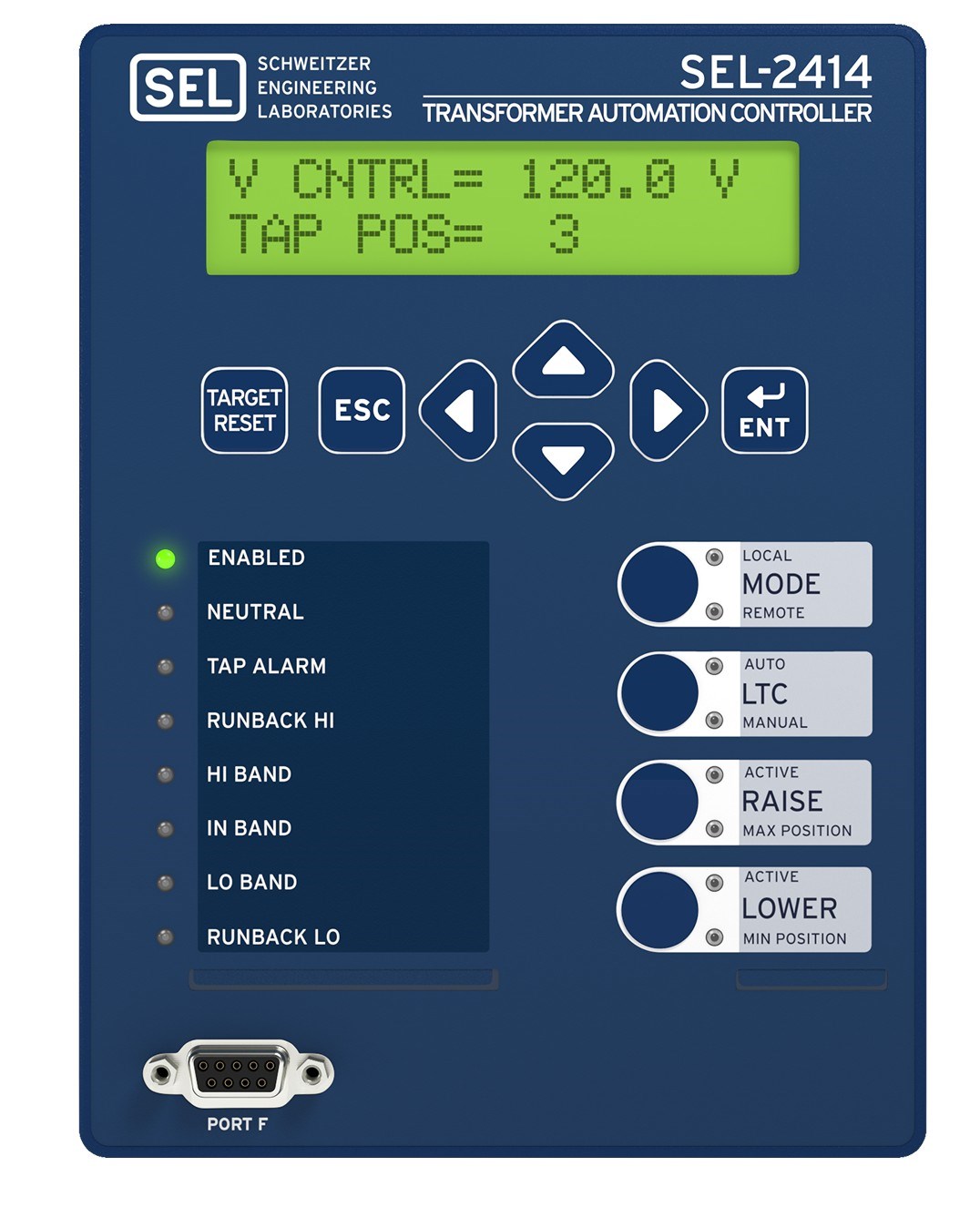

- 1

Customize display messages or use the default messages to support control and diagnostics viewing.

- 2

Navigate the onscreen menus by using simple directional pushbuttons.

- 3

Execute commands by using programmable pushbuttons.

- 4

Alert personnel of controller status and conditions by using programmable pushbuttons and LEDs.

- 5

Install in the most extreme environments. The SEL-2414 has an operating temperature range of –45° to 85°C (–49° to +185°F).

12345

-

-

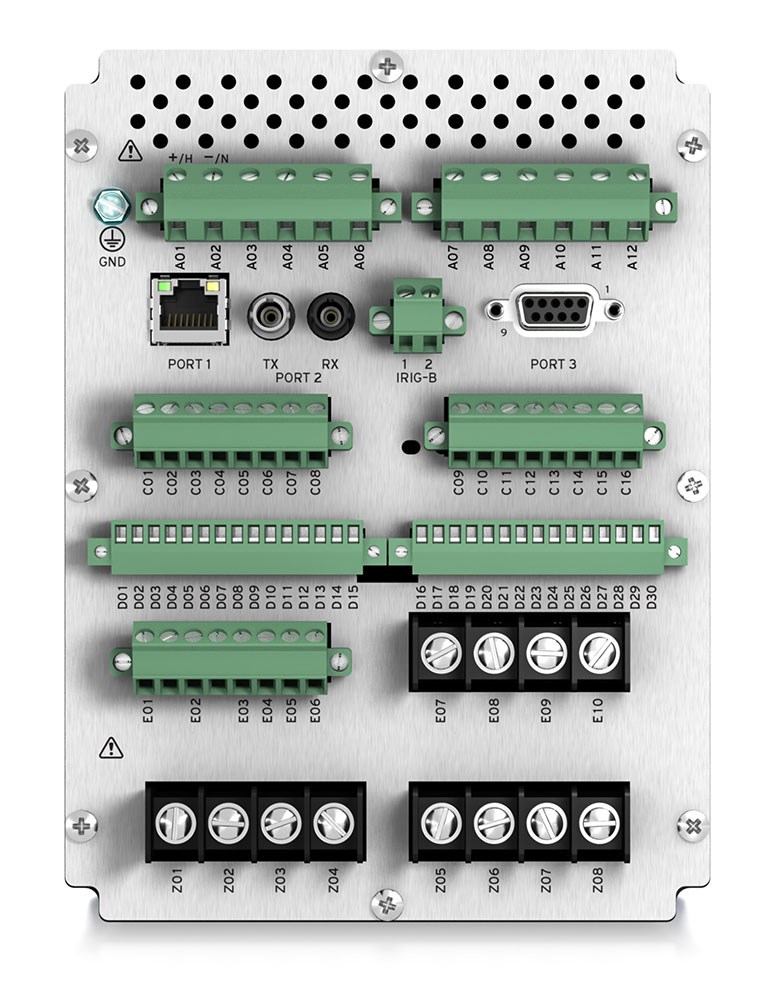

- 1

Select from a range of power supply options, including a 24/48 Vdc option and a 110/250 Vdc, 110/230 Vac option.

- 2

Accelerate firmware downloads and support transformer paralleling via the Ethernet port.

- 3

Configure I/O to fit your installation by using four available slots and a range of orderable I/O cards.

- 4

Standard I/O includes three digital outputs and two digital inputs.

- 5

Trust the SEL-2414 for proven quality and reliability, as it meets the same IEC standards as SEL protective relays.

12345

-

Details

Transformer LTC Control

Configure parameters for bandwidth voltage control, tap duration, and tap delays. Control the LTC during forward power flow and reverse power flow conditions using locked-forward, locked-reverse, bidirectional, and cogeneration operating modes. The controller compensates for voltage drops on the line between the transformer and the load center. To force the LTC into a neutral position, use the run-to-neutral function.

Cooling Bank Control

Improve energy efficiency by automating cooling systems to adapt to changing load and weather conditions. Automate fan and/or oil pump bank alternation and exercising to balance wear and prevent mechanical seizure.

Transformer Paralleling

Operate transformers in parallel by using up to four SEL-2414 controllers and using preconfigured Ethernet settings to coordinate tap positions and maintain voltage. Choose from leader/follower or current angle control methods for reliable transformer paralleling.

Transformer Monitoring

Use the SEL-2414 for thermal, through-fault, and voltage monitoring. Monitor up to 32 tap positions and up to 3 neutral LTC positions. Activate alarms based on the thermal condition of the transformer or other monitoring conditions. With tap-change limit and hunting alarming capabilities, the controller maintains voltage stability and prevents equipment damage.

Flexible I/O for Local Control and System Applications

Choose I/O options that include digital inputs for statuses, such as oil level and sudden pressure, as well as load tap position control and monitoring; RTD inputs for measurements such as ambient, top-oil, and hotspot temperatures; digital outputs for control and alarms; analog inputs and outputs; and ac current and voltage inputs.

Extensible Logic Engine

Customize your device with powerful math and logic. Use control equations with logic, arithmetic, analog comparison, edge-trigger, and timer functions for automatic local control and to combine data into system information. Time-deterministic, high-speed processing is ideal for time-critical applications.

Critical Reporting and Logging

Store up to 1024 Sequential Events Recorder (SER) reports of digital input transitions, which are time-stamped to the nearest millisecond. Analyze SER reports, analog trending, and oscillographic event reports for rapid commissioning, testing, and post-event diagnostics. Trigger event reports of voltage, current, and Device Word bit status in EVE, CEV, and COMTRADE formats.

Reliable Integration With SCADA

Flexible communications options provide reliable integration with SCADA. Choose preferred protocols from Modbus, DNP3, IEC 61850 Edition 2 (including mode behavior), the Parallel Redundancy Protocol (PRP), the Simple Network Time Protocol (SNTP), Precision Time Protocol (PTP), the Rapid Spanning Tree Protocol (RSTP), Telnet, Ethernet File Transfer Protocol (FTP), and SEL protocols like Mirrored Bits communications, SEL Fast Meter, SEL Fast SER, SEL ASCII, and binary communications protocols.

Rugged Hardware Design

Built to the same standards as SEL protective relays, the SEL-2414 withstands vibration, electrical surges, fast transients, and extreme temperatures, meeting stringent industry standards. For even harsher environments, order conformal coating for the printed circuit boards to provide an additional barrier to severe environments and airborne contaminants such as hydrogen sulfide, chlorine, salt, and moisture.

AC Metering Capabilities

Measure and record voltage, current, power, energy, power factor, and frequency; demand/peak demand metering; and maximum/minimum metering with extensive ac metering and monitoring capabilities. Apply values in programmable calculations and triggers within the meter.

- Monitor transformer life and hot-spot temperatures.

- Control transformer cooling stages.

- Metering information, including max./min., demand, peak demand, and energy.

- Monitor transformer life and hot-spot temperatures.

- Control transformer cooling stages.

- Monitor and control load tap changer.

- Metering information, including max./min., demand, peak demand, and energy.

Minimum Software Version

| Product | Revision | Z Number | acSELerator QuickSet Version | SEL Grid Configurator Version |

|---|---|---|---|---|

| SEL-2414 | R400-V5 | 013 | 6.10.12.0 | |

| SEL-2414 | R400-V4 | 013 | 6.10.12.0 | |

| SEL-2414 | R400-V3 | 013 | 6.10.12.0 | |

| SEL-2414 | R400-V2 | 013 | 6.10.12.0 | |

| SEL-2414 | R400-V1 | 013 | 6.10.12.0 | |

| SEL-2414 | R400-V0 | 013 | 6.10.12.0 | |

| SEL-2414 | R315-V1 | 012 | 6..7.0.2 | |

| SEL-2414 | R314-V0 | 011 | 6.6.0.0 |

Latest Firmware Versions

There are no firmware versions available for this product.

| Product | Revision | Firmware ID | Date Available | Serial Number |

|---|---|---|---|---|

| SEL-2414 | R502-V0 | SEL-2414-R502-V0-Z101200-D20260116 | 1/28/26 | 3260280001 |

The Firmware IDs for older versions of the firmware can typically be found in Appendix A of the instruction manual.

Minimum Software Version

| Product | Revision | Z Number | acSELerator QuickSet Version | SEL Grid Configurator Version |

|---|---|---|---|---|

| SEL-2414 | R400-V5 | 013 | 6.10.12.0 | |

| SEL-2414 | R400-V4 | 013 | 6.10.12.0 | |

| SEL-2414 | R400-V3 | 013 | 6.10.12.0 | |

| SEL-2414 | R400-V2 | 013 | 6.10.12.0 | |

| SEL-2414 | R400-V1 | 013 | 6.10.12.0 | |

| SEL-2414 | R400-V0 | 013 | 6.10.12.0 | |

| SEL-2414 | R315-V1 | 012 | 6..7.0.2 | |

| SEL-2414 | R314-V0 | 011 | 6.6.0.0 |

Instruction Manuals

Sales Resource Central access is required to view the content in this tab.

Sales Resource Central2414 - Software Tab

Configuration

acSELerator QuickSet SEL-5030 Software

QuickSet is a tool for engineers and technicians to quickly and easily configure, commission, and manage power system devices. QuickSet includes a Graphical Logic Editor and a device template tool to reduce configuration time and streamline deployment.

Learn more and download on the QuickSet software page.

acSELerator Architect SEL-5032 Software

Architect allows users to configure and document IEC 61850 systems that include GOOSE, Sampled Values (SV), or Manufacturing Message Specification (MMS) communications. Architect automatically compares SCL files with IEC 61850 requirements to ensure standard compliance.

Learn more and download on the Architect software page.

Visualization & Analysis

SEL-5601-2 Synchrowave EVENT SOFTWARE

Synchrowave Event helps engineers diagnose the cause of power system disturbances, including faults. It is a powerful and easy-to-use solution for displaying and analyzing SEL event reports and COMTRADE files.

Learn more and download on the Synchrowave Event software page.