SEL-7203

Distribution Transformer Protection Panel

SEL-7203 panels provide advanced protection and control for distribution transformers with a single high-/low-side transformer zone boundary. These panels include the following features:

- Fully redundant differential protection

- Restricted earth fault (REF) protection

- Transformer through fault overcurrent backup protection

- High-speed bus protection using a zone interlock (fast bus blocking) scheme with a partial differential accommodating a single bus-tie breaker

- Time-coordinated system backup protection with a partial differential accommodating a single bus-tie breaker

- Breaker failure protection

- Trip circuit monitor

- Transformer and breaker alarm monitoring

- Remote breaker control via communications

- Digital lockout and reset logic for 86T and 86BF

- Battery and breaker wear monitoring

- Sequential Events Recorder (SER)

- Load profile reporting

- Dimensions of 92" tall × 28" wide × 28" deep

- Customizable wire labels to match your existing nomenclature

- Customizable nameplates to meet your nomenclature needs

- Drawing package

- Automation and communications modules available

Starting At

$55,900Available Application Modules

SEL-787/SEL-751 Transformer Protection Module

This module is always required and provides transformer differential and bus zone interlock protection using the SEL-787 Transformer Protection Relay, high-side breaker/circuit switching, motor-operated air break control, and sudden pressure tripping supervision. It also provides overcurrent through-fault and system backup protection using an SEL-751 Feeder Protection Relay and can perform direct transfer tripping if there is no local high-side interrupter.

View Product Info

SEL-787 Redundant Transformer Protection Module

This module is always required and provides redundant transformer differential protection, REF protection, overcurrent through-fault protection, and low-side breaker control and breaker failure protection.

If the station includes a bus-tie breaker, a version of the module that includes an SEL-751 breaker control relay is available. This relay provides breaker control with breaker failure, synchrocheck, and voltage monitor supervision. The tie breaker relay can also provide arc-flash protection if the buses are covered by arc-flash sensors.

View Product Info

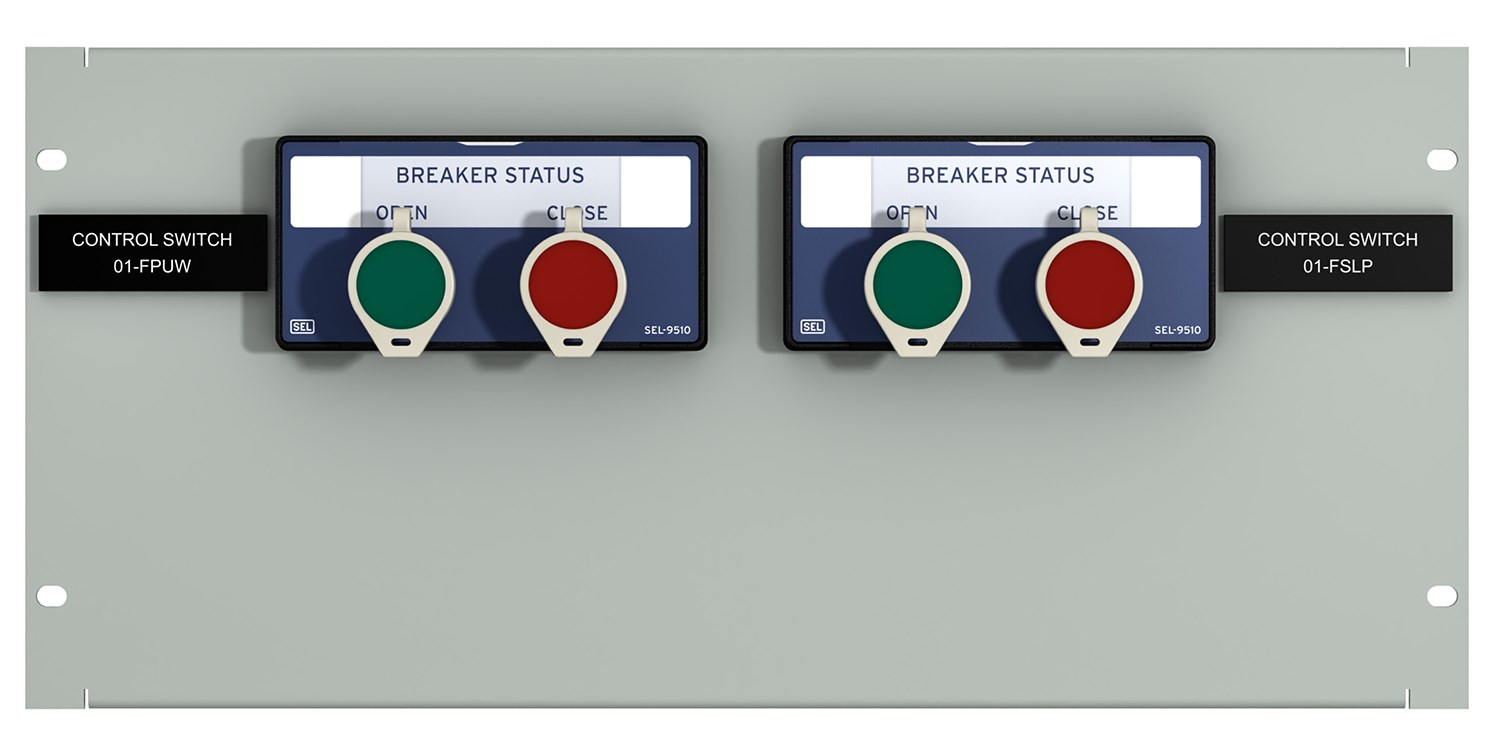

SEL-9510 Control Switch module

This module provides independent local control and indication for up to four switching devices.

View Product Info

Rotary Control Switch Module

This module provides independent local control and indication for up to three switching devices using rotary switches.

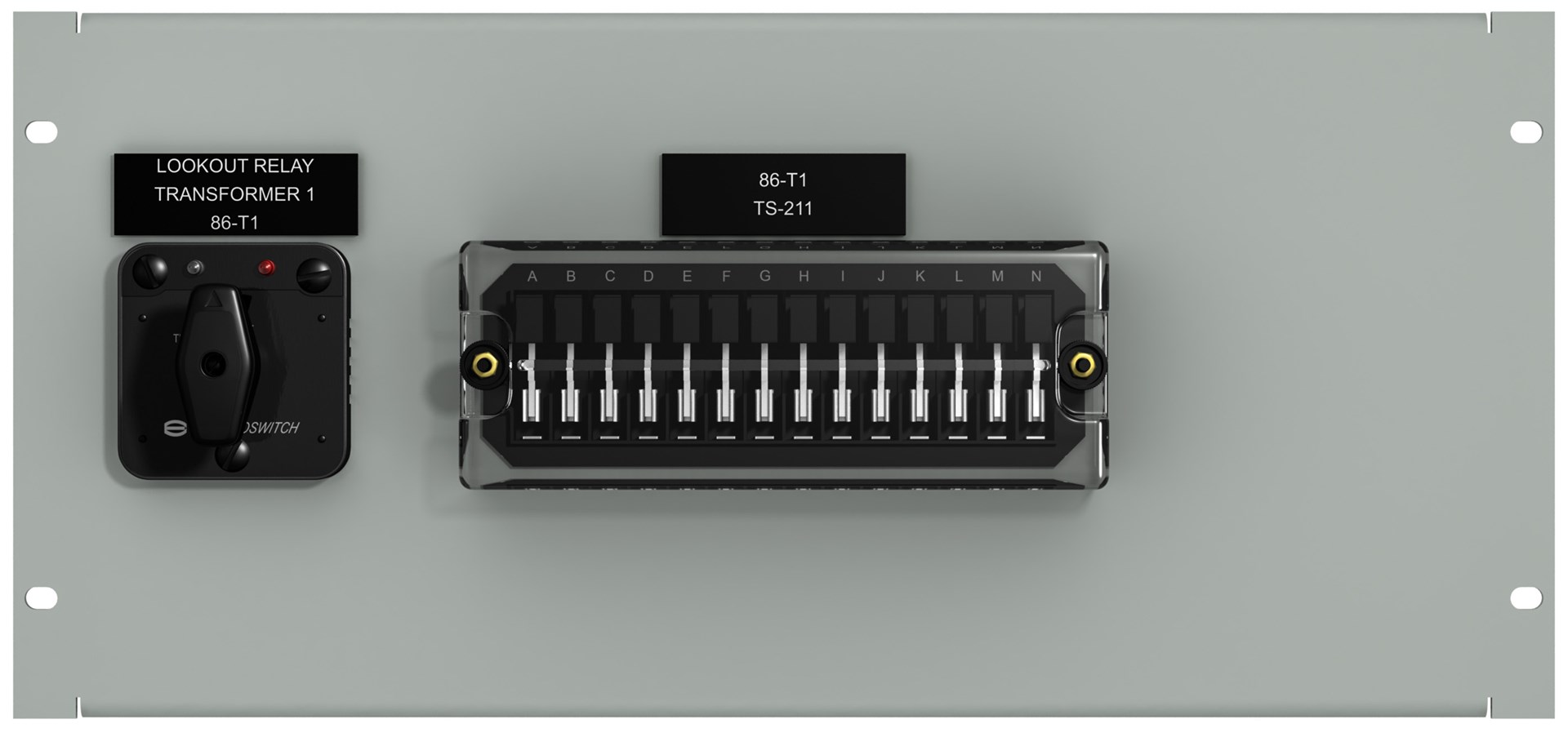

Lockout Relay Module

This module provides independent mechanical lockout for the transformer protection (86T) and/or breaker failure protection (86BF) using rotary lockout switches.

Details

SEL CTO panels embody SEL best-known engineering methods and field-tested expertise in mechanical design, cable management, protection, precise time, automation, communications, and metering.

Application modules support common protection and automation practices while universal wiring to terminal blocks allows customization flexibility to adapt to any common primary equipment configuration and operation practice.

The SEL Difference

SEL uses the same world-class manufacturing principles for our panels that we use for all our industry-leading products. This allows us to design, manufacture, test, and deliver top-quality and comprehensive panel systems.

Complete vertical integration and standardized application designs help us maintain competitive prices and high quality while still meeting the highest functionality requirements.

Design Principles

SEL CTO panels provide the following:

- Fully redundant protection and breaker failure protection at all voltage levels.

- Preconfiguration for cybersecurity framework integration.

- Advanced SEL technology, such as arc-flash protection, zone-interlocked bus protection logic, and negative-sequence overcurrent protection, that is ready to deploy.

- Simple integration to SCADA and HMI.

- Continuous monitoring to reduce the possibility of hidden failures and facilitate extended testing intervals.

- An industrial design for improved human performance.

Design Validation That Guarantees Expected Performance

We build a prototype and test each application module design to ensure it meets functional specifications. This process allows our manufacturing facility to properly document processes and test manufacturing equipment for production.

Drawing Package

SEL CTO panels come with comprehensive information using best practices for documenting protection and control circuitry. With standardization, the level of error-free detail is unmatched compared to what is practical with custom panels. SEL drawing packages are personalized to your substation project and nomenclature and include:

- Application-specific circuit information.

- One-line diagram customized with your primary equipment information.

- AC schematics diagrams documenting relay sensing circuits, protection functions, and space to incorporate customer primary equipment information.

- DC schematic diagrams with panel control circuits and space to include external connection points from marshalling cabinets and primary equipment.

- Comprehensive logic diagrams documenting logic settings for the application, including local/remote control and indication, target LEDs, fault protection, alarms, event report triggers, open, close, reclose, and trip.

- Panel layout drawing containing device locations, dimensions, and anchoring details.

- Wiring diagram with wiring label nomenclature.

- Nameplate drawing that includes all labels created and installed in the panel.

Quality

We engineer, manufacture, and test our panels to ensure adequate operation before delivery. When a panel arrives at your site, it is already verified as fully functional.

Warranty and Support

SEL panels are supported by an unmatched ten-year warranty and the industry’s best customer service.

The Firmware IDs for older versions of the firmware can typically be found in Appendix A of the instruction manual.