SEL-7250

Digital Direct-Replacement Assemblies

Streamline retrofit projects with SEL digital direct-replacement assemblies for motor, generator, transformer, feeder, and metering protection applications. These complete, preassembled retrofit kits are designed to closely match the features, form factor, and terminal blocks of specific legacy products. They combine field-proven SEL devices with specialized mounting plates, interposing terminal blocks, and other hardware to ensure quick, seamless, and cost-effective upgrades.

Upgrade Devices Across Applications—We offer digital direct-replacement assemblies for motor, generator, transformer, bus, feeder, and metering applications.

Strengthen Systems With All-New Hardware—Legacy hardware is prone to degradation and wear that reduces the reliability of your equipment. SEL digital direct-replacement assemblies do not repurpose any existing hardware.

Simplify Installation and Configuration—Digital direct-replacement assemblies deliver an installation experience that is easy, fast, and error-free. The physical installation work for each unit can be completed within an hour—without any power tools. Panel cuts and drilling are not required; instead, each assembly fits the existing panel opening and mounting holes. Terminal block arrangements and wiring designations closely match legacy products, and SEL provides wiring labels with the retrofit kits to complete the upgrade process.

Minimize Engineering Work—Eliminate time-intensive and costly engineering tasks, such as revising drawings and diagrams. All assembly kits include wiring diagrams, so existing documentation for your system is not required for installation.

Partner With SEL on a Turnkey Solution—SEL offers services that include system design, settings conversion, installation, and commissioning—everything needed for a complete turnkey retrofit solution. We also create custom assembly designs to meet specific protection, communications, and mounting requirements.

Receive Comprehensive Support—All SEL-manufactured products and workmanship within panels and enclosures are backed by a worldwide, ten-year warranty. Diagnostic services, repairs, and local technical support are available for the lifetime of every SEL-manufactured device—at no extra cost. Third-party devices carry a transferred manufacturer warranty.

Purpose-Built Replacements

The following assemblies are now available, providing direct replacements for a range of legacy devices. SEL Engineering Services also accommodates requests for custom assembly designs to meet specific protection, communications, and mounting requirements.

Features

- ABB DPU2000 Relay

- ABB DPU2000R Relay

- ABB REF542plus Relay

- ABB TPU2000 Relay

- ABB TPU2000R Relay

- Beckwith M-2001 LTC Controller in M-2067 Mount

- Eaton DT3000

- Eaton FP5000/6000

- Eaton PXM4000 Meter

- GE Multilin 139 and 239 Without RTDs

- GE Multilin 169, 269, and 369 Relays With RTDs

- GE Multilin 169, 269, and 369 Relays Without RTDs

- GE Multilin 350 Relay

- GE Multilin F650 Relay

- GE Multilin Protect 4A Relay

- GE Multilin SPM Relay

- GE Multilin SR Family of Relays

- ION 7550/7650 Meters

- ION 8600/8650 Meters

- Janitza UMG 509-Pro/UMG 512-Pro Meters

- Schneider MiCOM P145 Relay

- Schneider MiCOM P643 Relay

- Schneider PM800/PM8000 Meters

- Schneider Sepam Family of Relays

- Siemens 9410 Meter

- Siemens SIMPRO-100 With RTDs

- Siemens Siprotec Family of Relays

- SquareD 2000 Meter

- Westinghouse/Cutler-Hammer/Eaton IQ-1000, IQ-1000II, MP-3000, and MP-4000 Relays

-

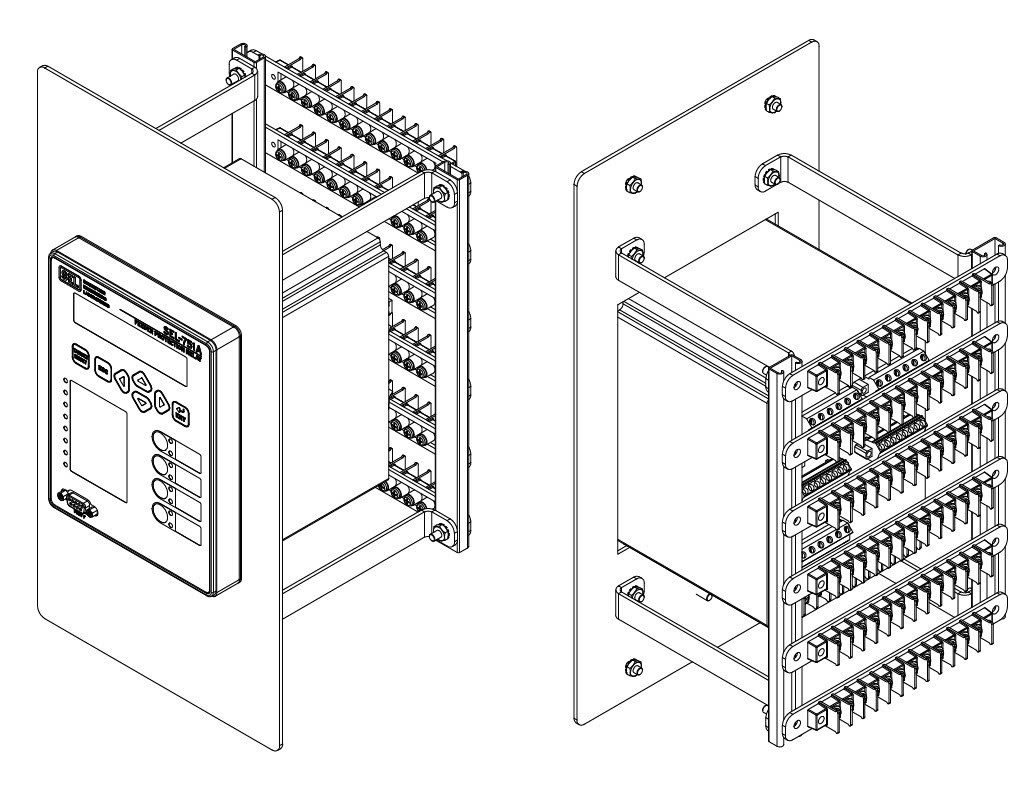

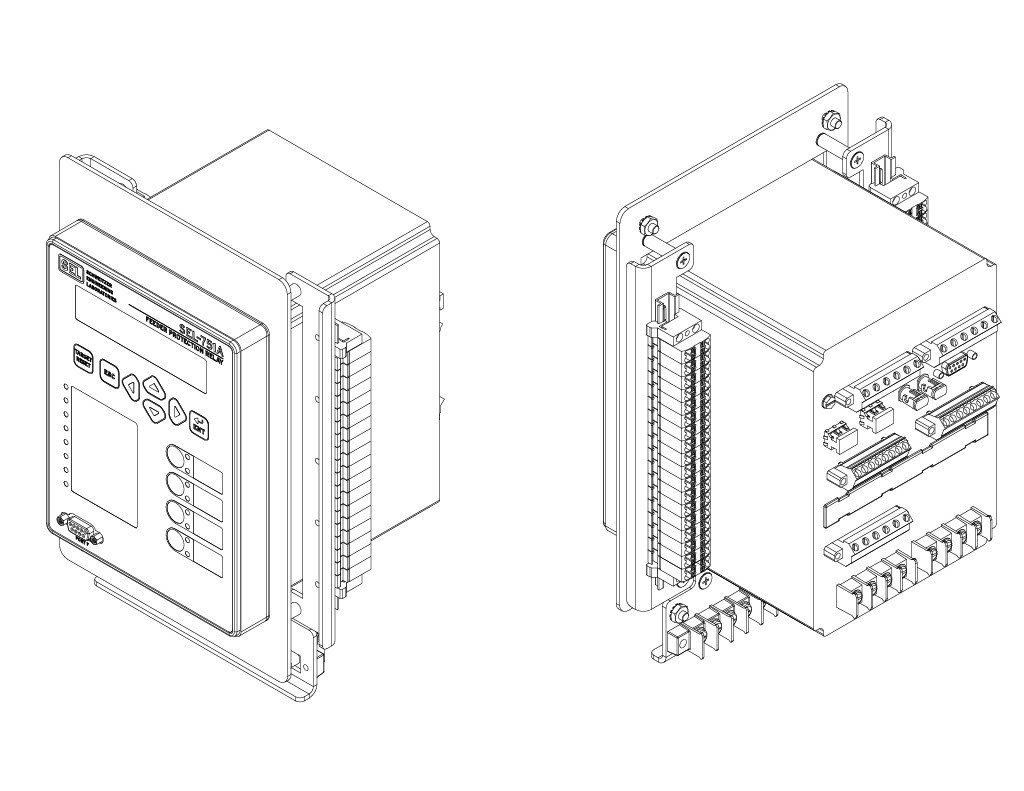

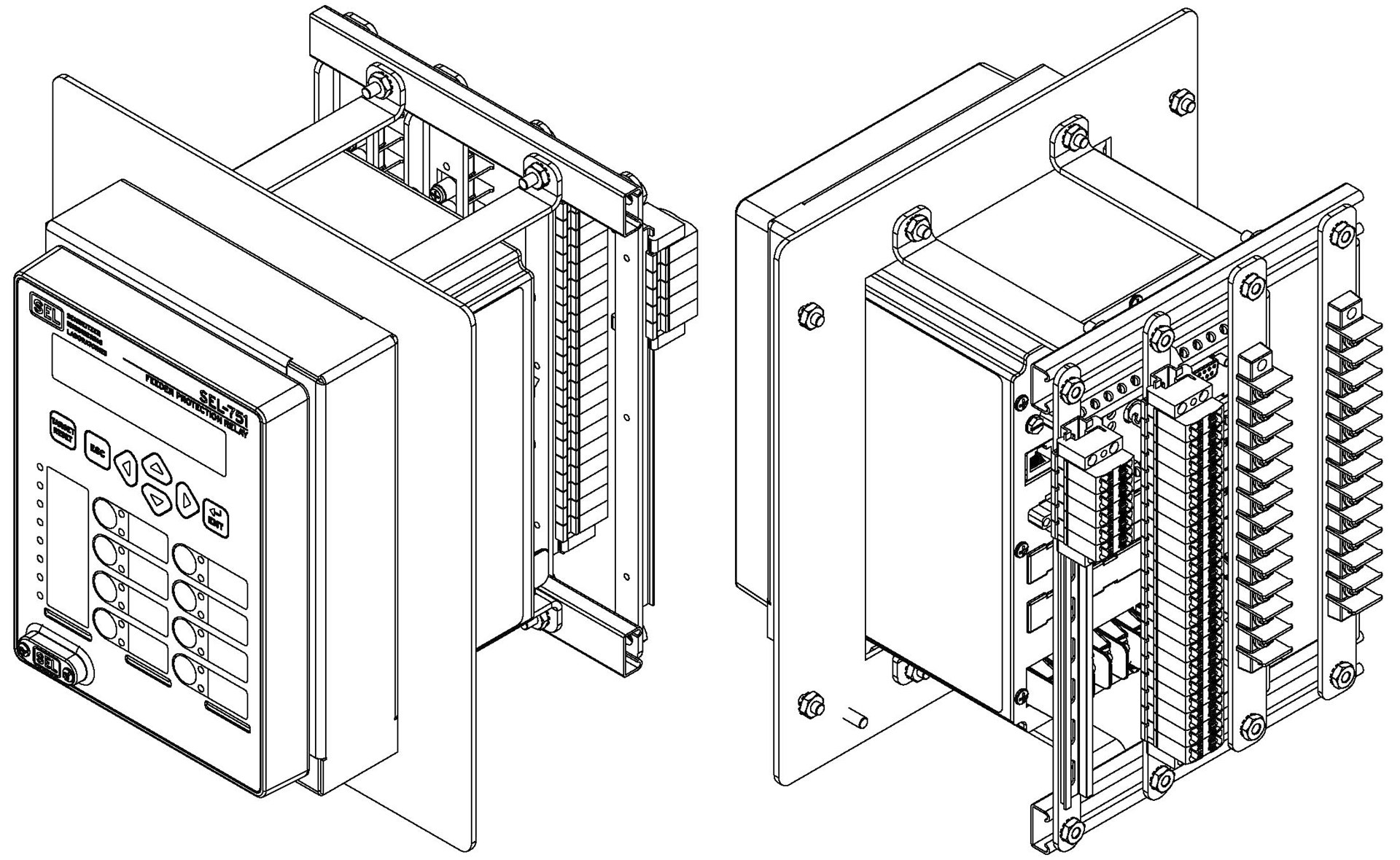

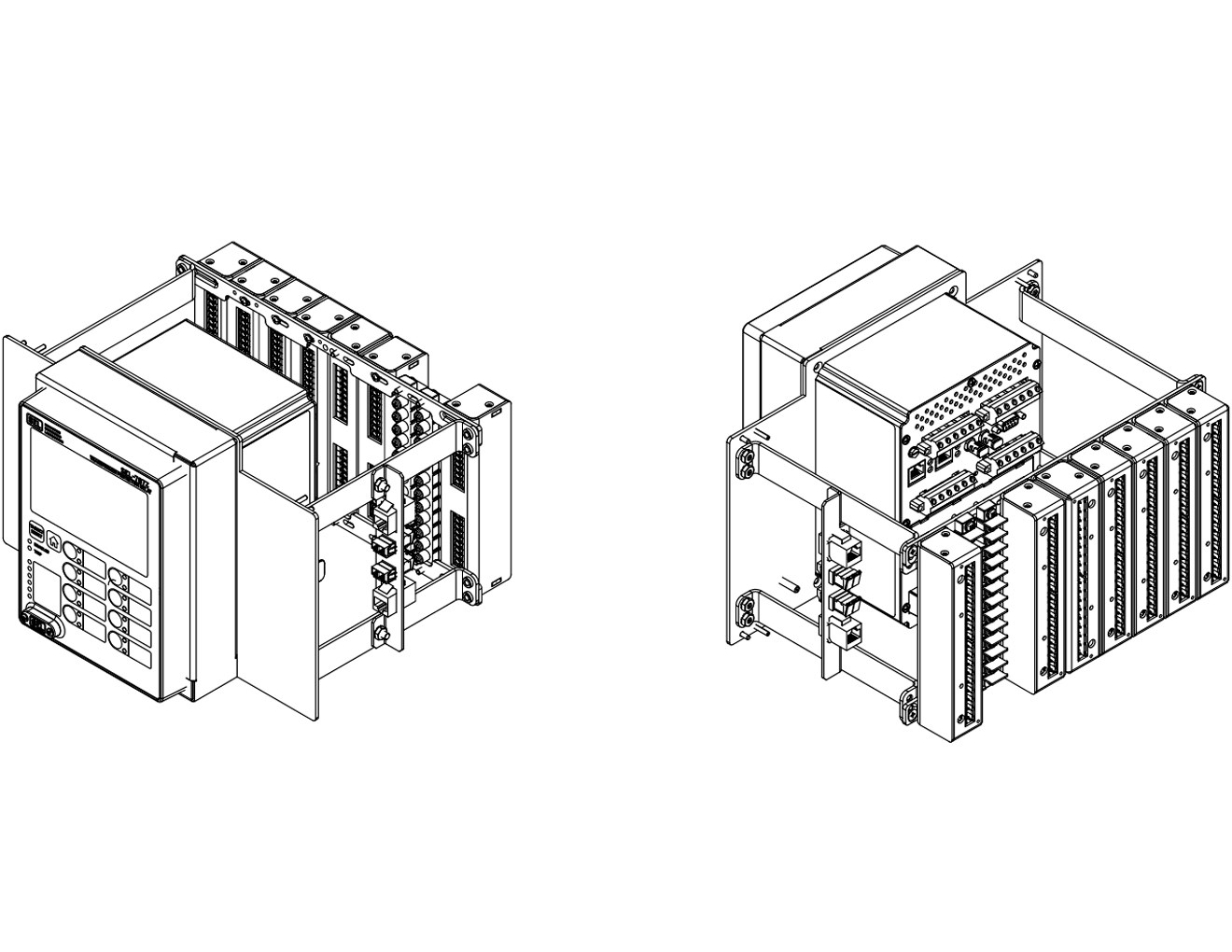

- 1

Control terminal block

- 2

SEL-751 Feeder Protection Relay

- 3

Mounting plate

- 4

Control terminal blocks

- 5

PT terminal blocks

- 6

CT terminal blocks

123456

-

-

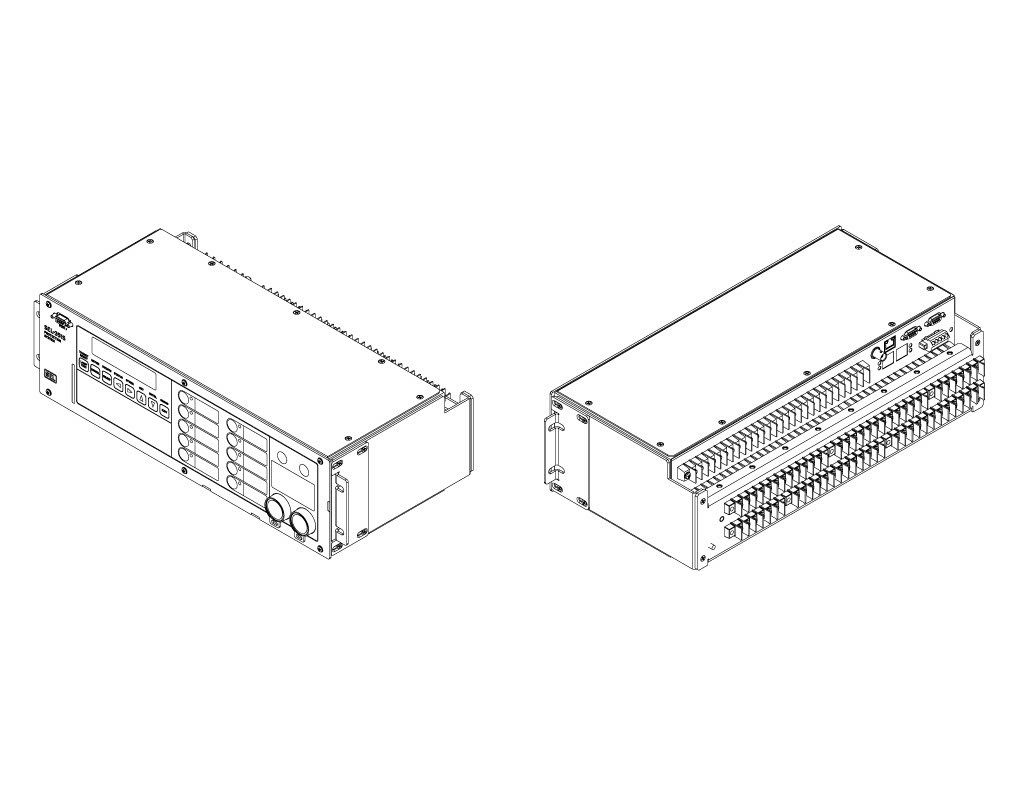

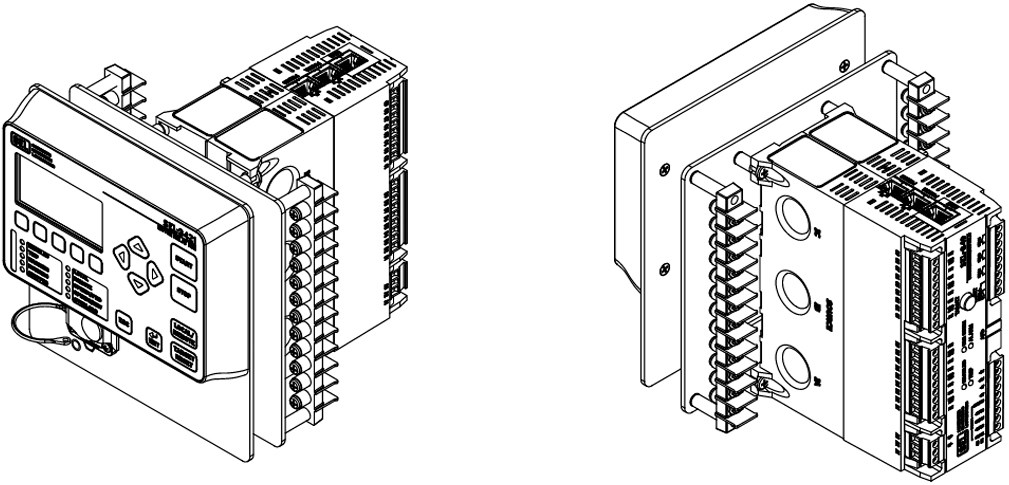

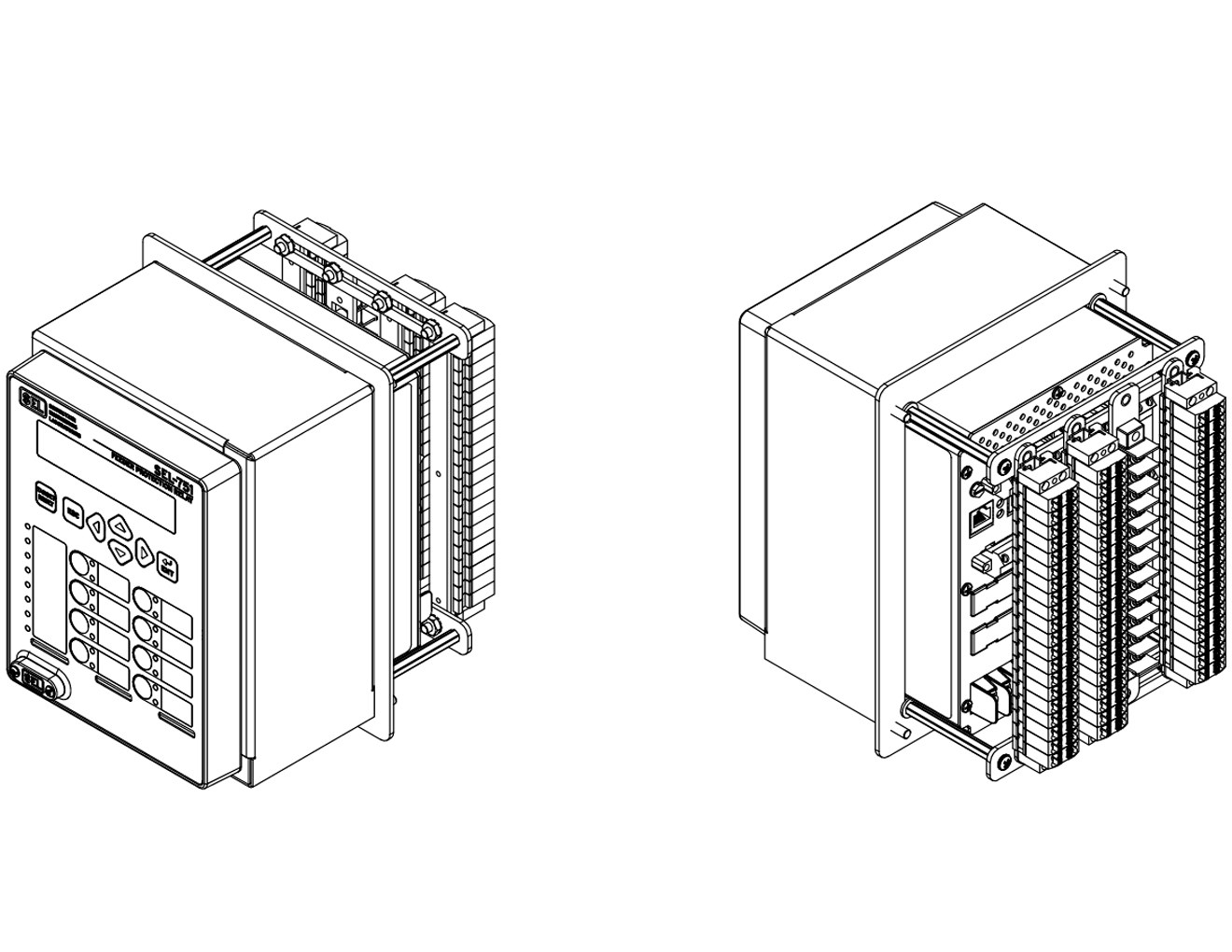

- 1

SEL-351S Protection System

- 2

Reversible mounting brackets

- 3

Terminal block adapter bracket

- 4

Fully accessible communication ports

1234

-

-

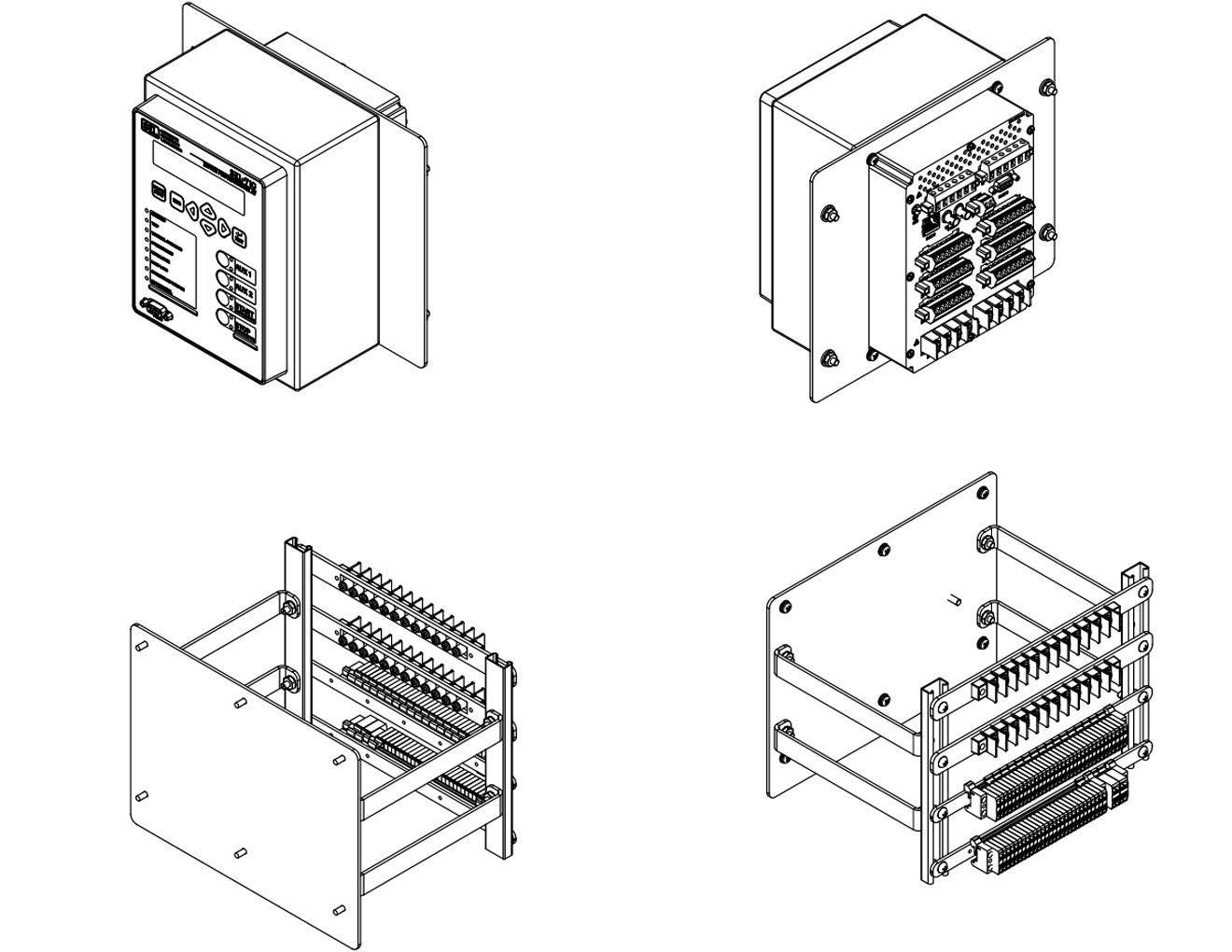

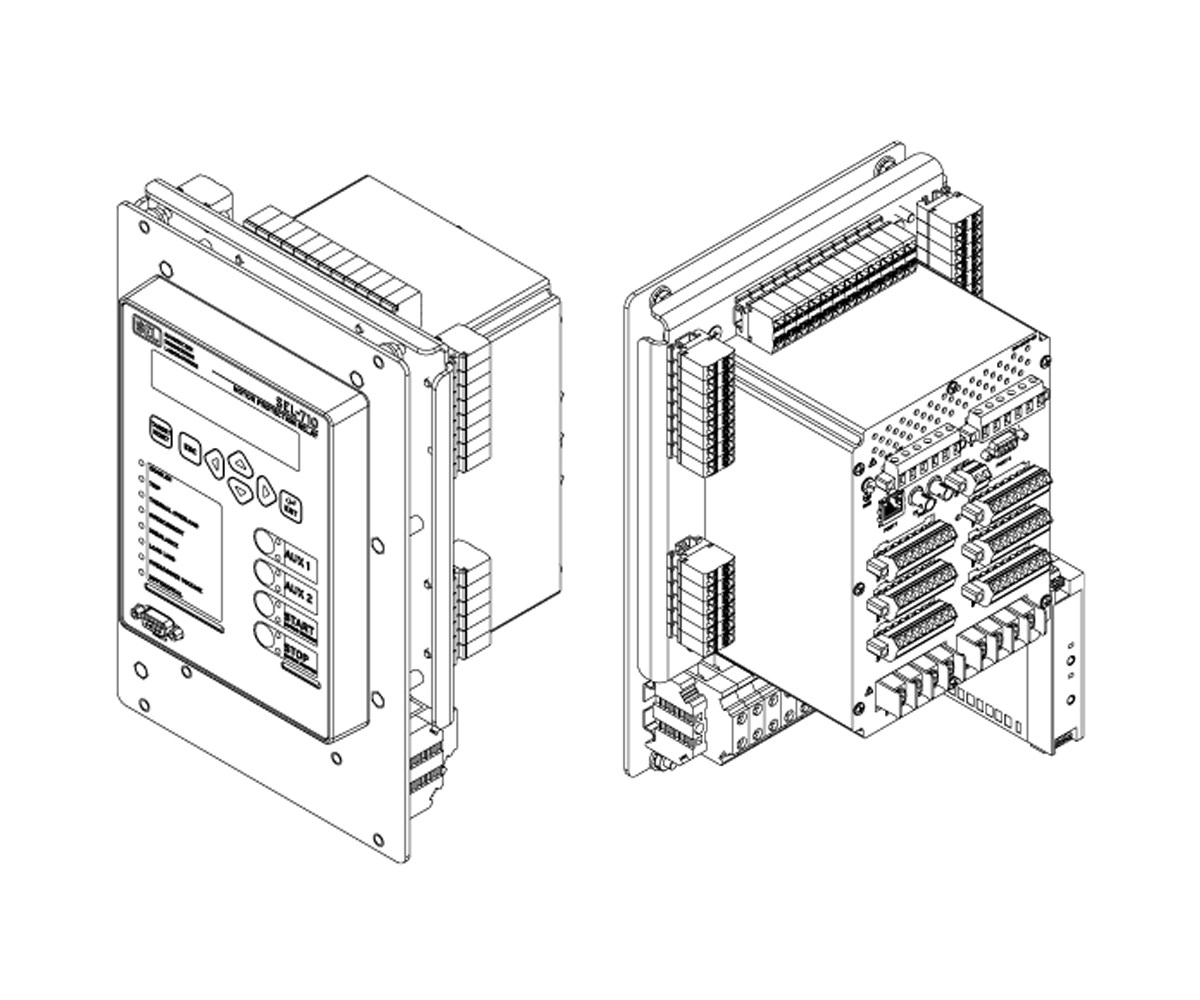

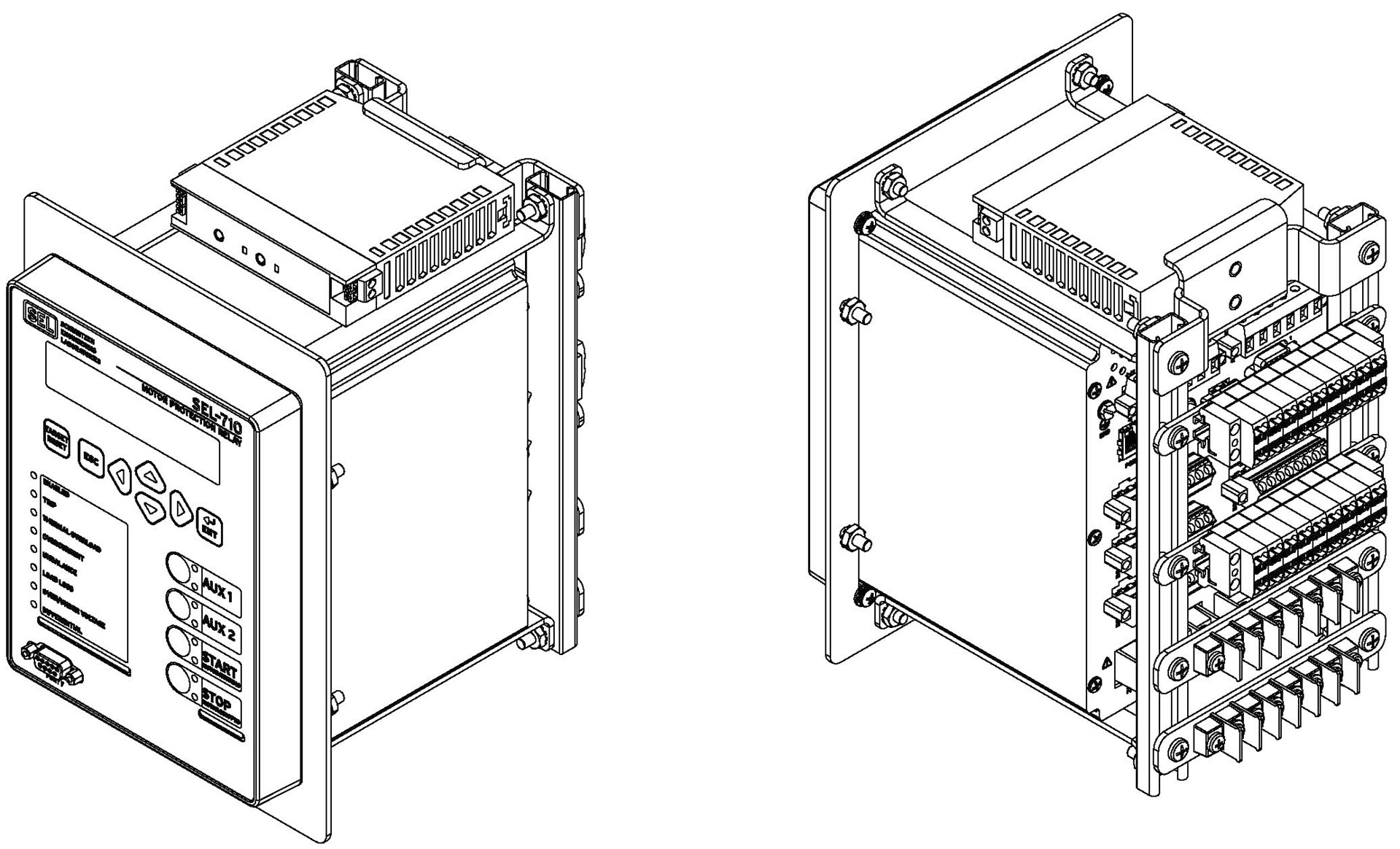

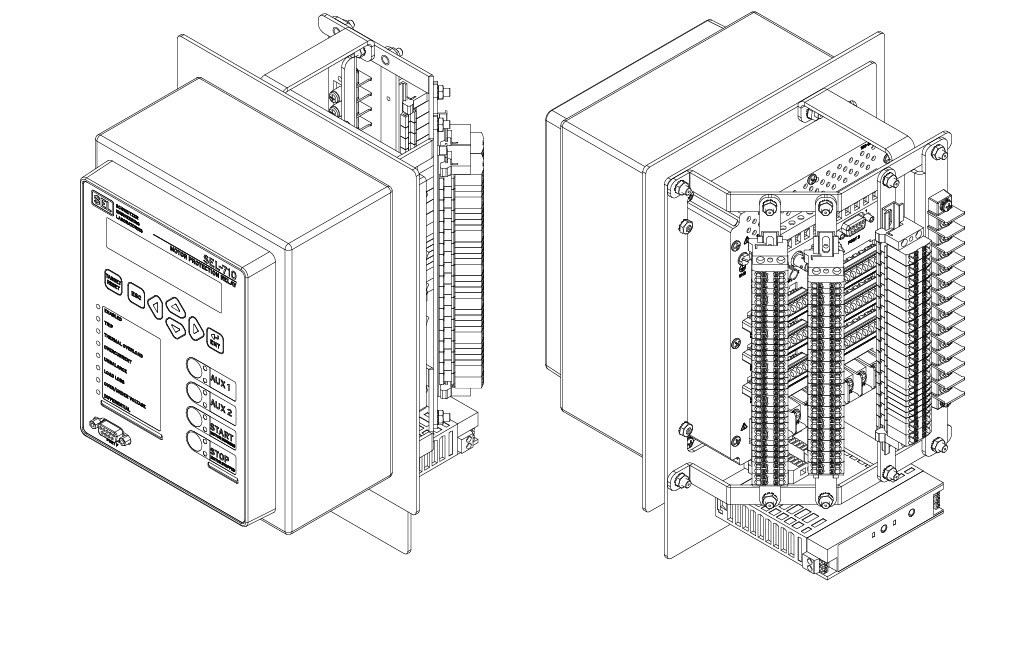

- 1

SEL-710 Motor Protection Relay

- 2

90 mm projection mount

- 3

Mounting plate

- 4

Preassembled frame

- 5

Control and RTD terminal blocks

- 6

CT and PT terminal blocks

123456

-

-

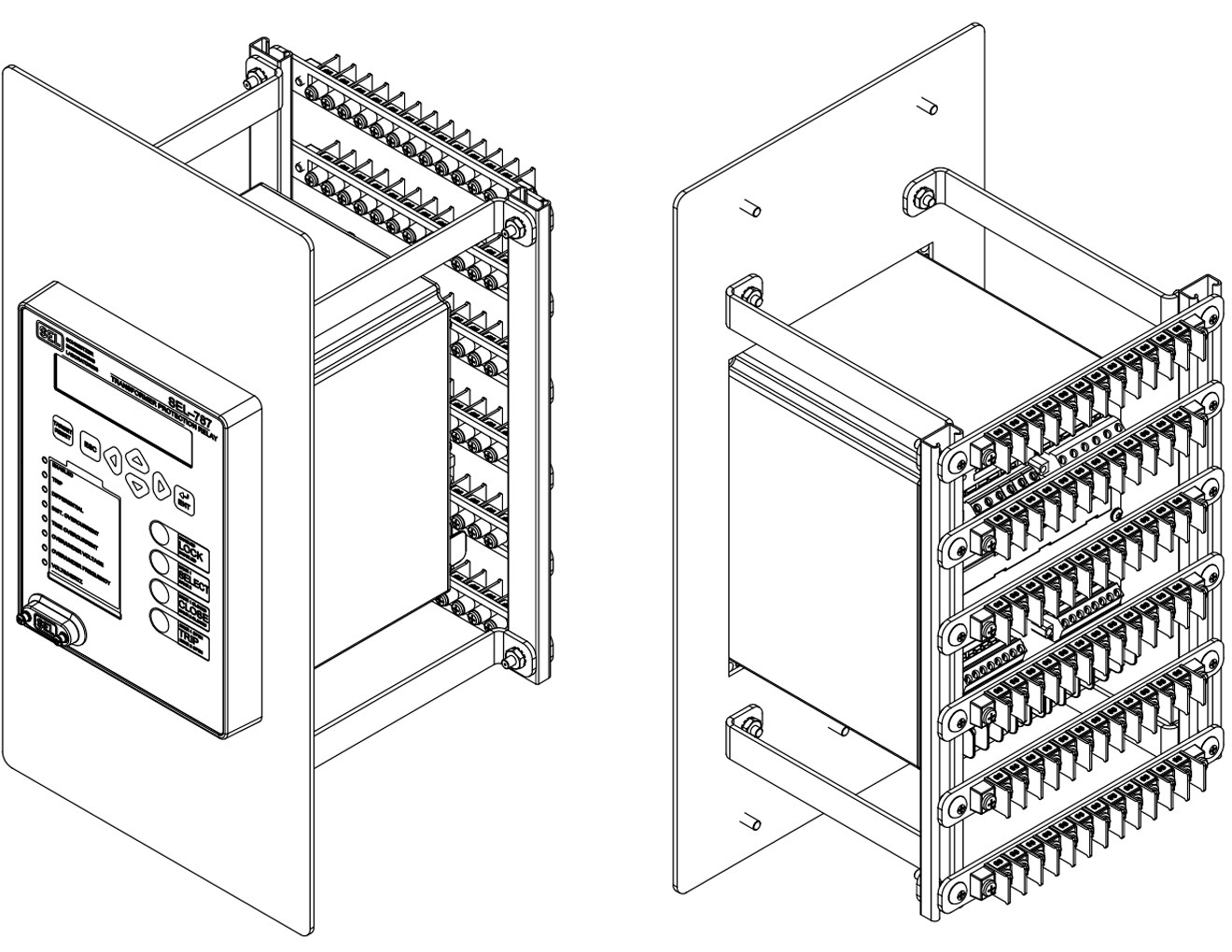

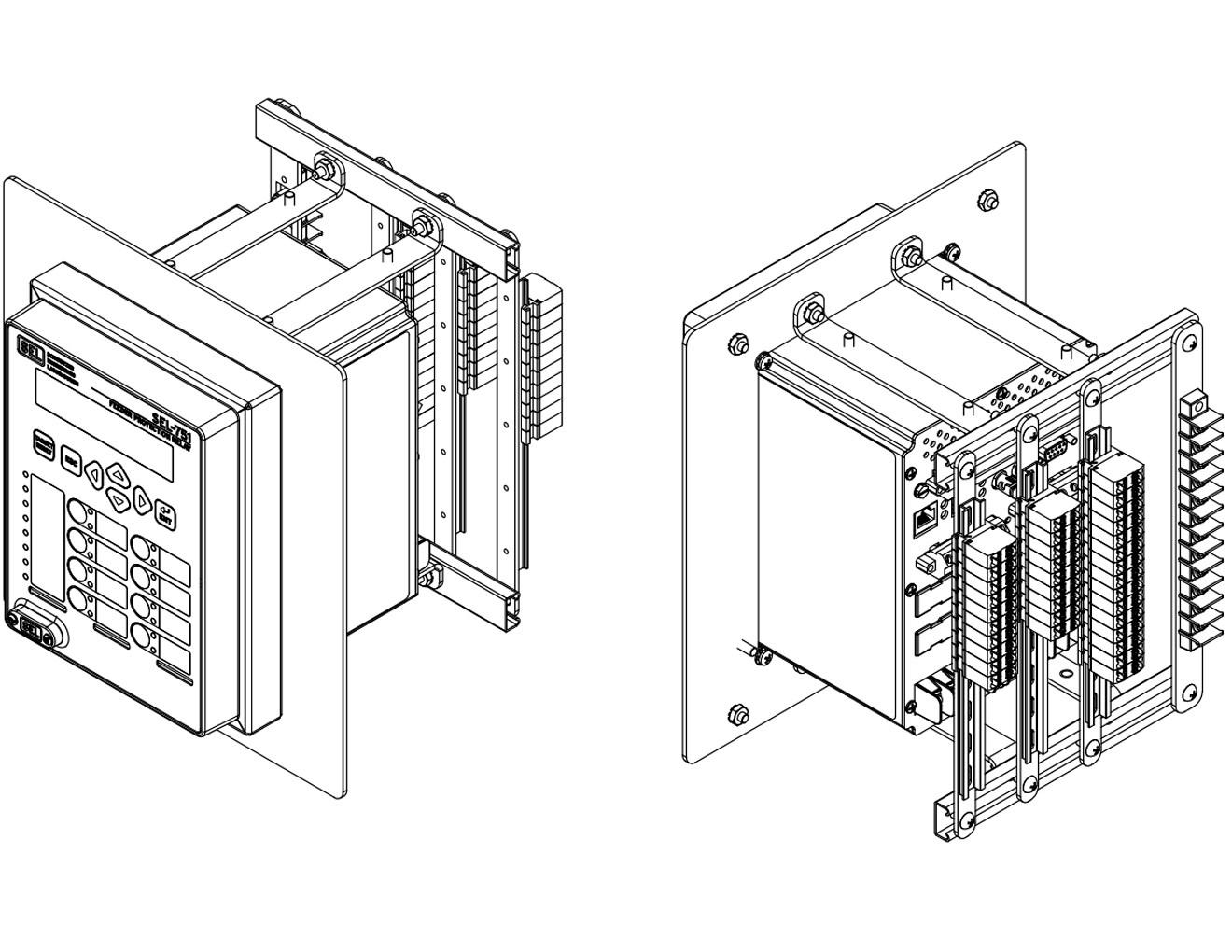

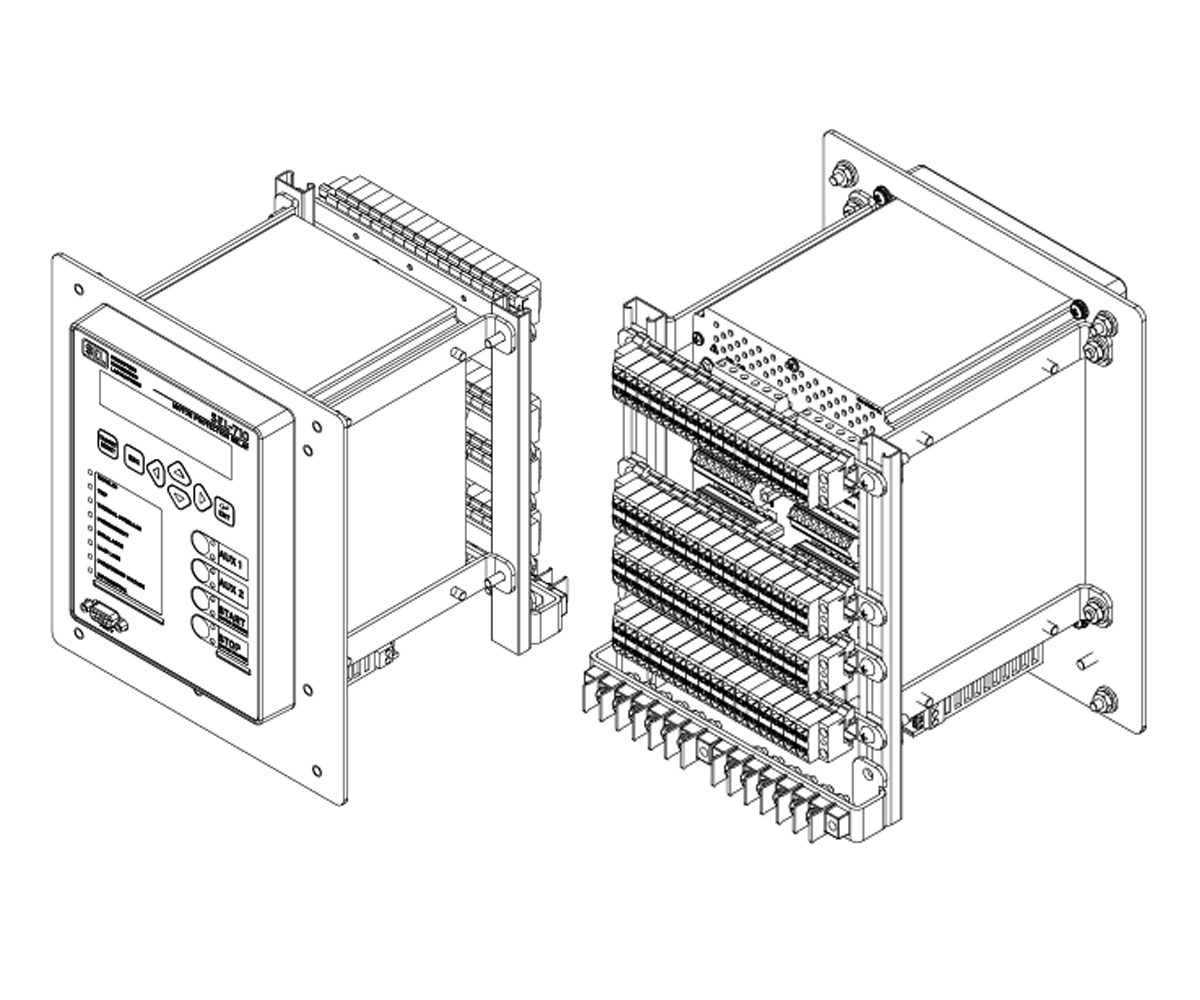

- 1

SEL-787 Transformer Protection Relay

- 2

Mounting plate

- 3

Preassembled frame

- 4

Control terminal blocks

- 5

PT terminal blocks

- 6

CT terminal blocks

123456

-

-

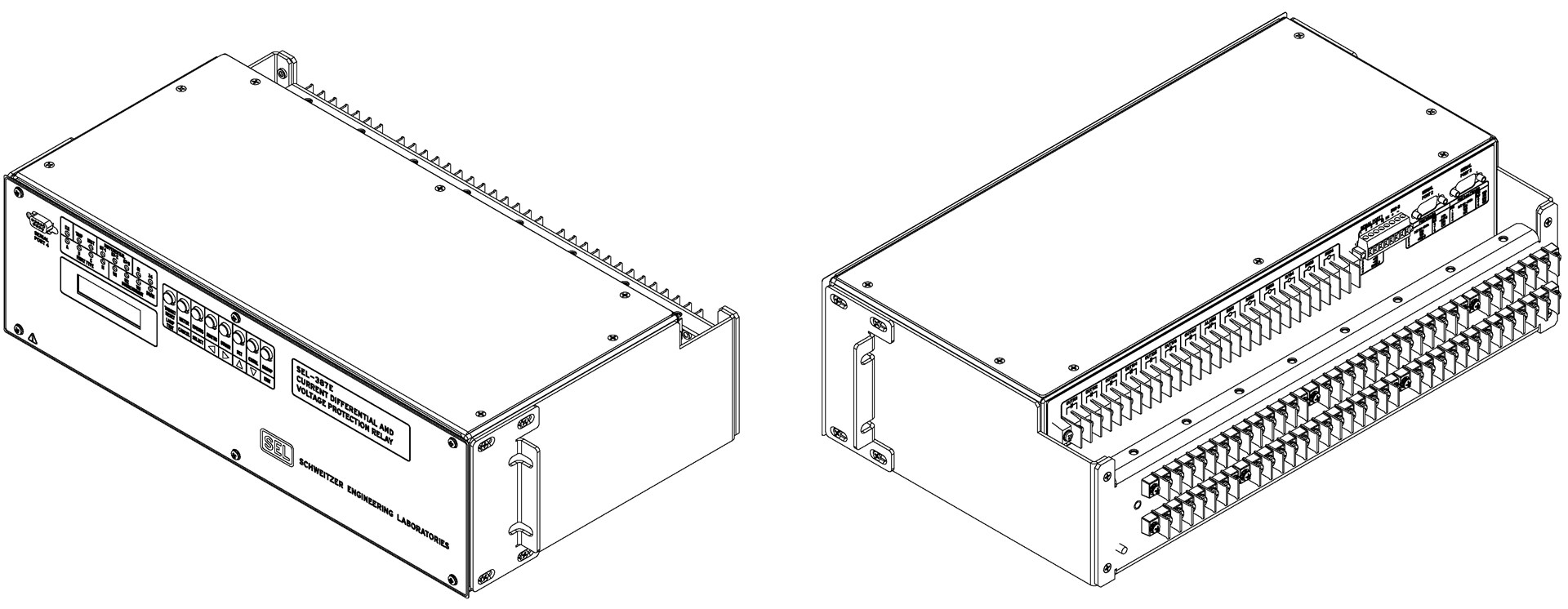

- 1

SEL-387E Current Differential and Voltage Relay

- 2

Reversible mounting brackets

- 3

Terminal block adapter bracket

- 4

Fully accessible communications ports

1234

-

-

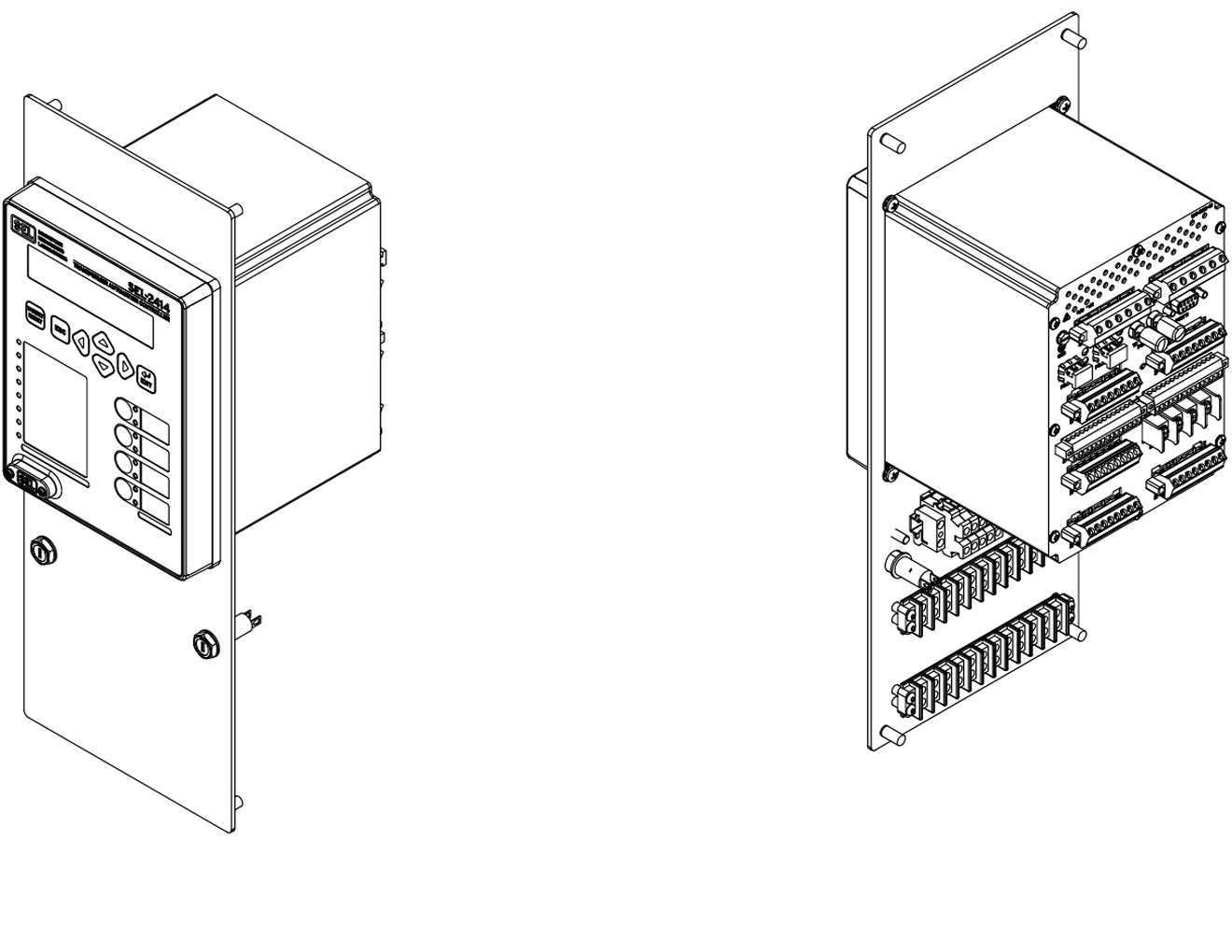

- 1

SEL-2414 Transformer Automation Controller (TAC)

- 2

Mounting plate

- 3

Terminal blocks

123

-

-

- 1

SEL-751 Feeder Protection Relay

- 2

Mounting plate

- 3

Control terminal blocks

- 4

CT and PT terminal blocks

1234

-

-

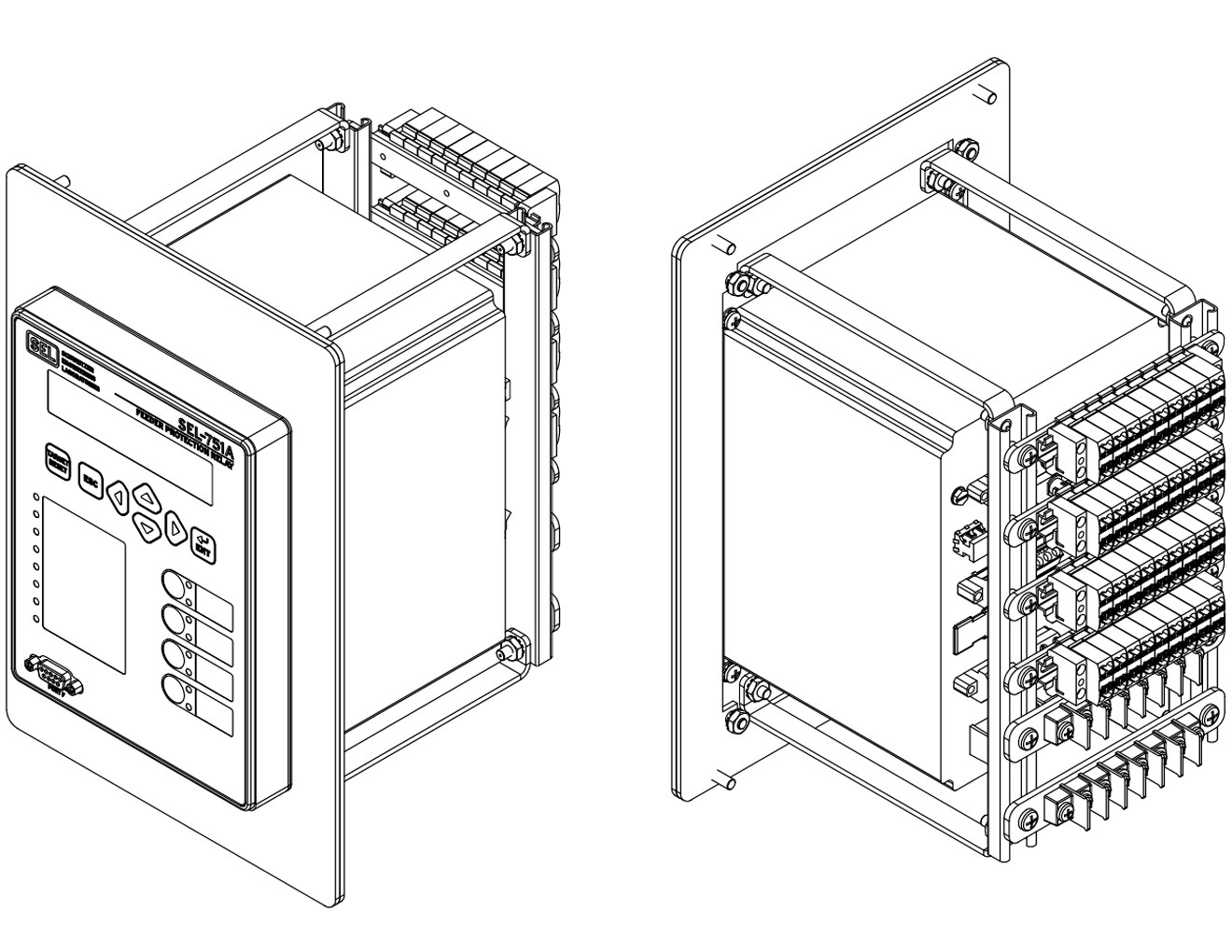

- 1

SEL-751 Feeder Protection Relay

- 2

Mounting plate

- 3

Preassembled frame

- 4

Control terminal blocks

- 5

CT and PT terminal blocks

12345

-

-

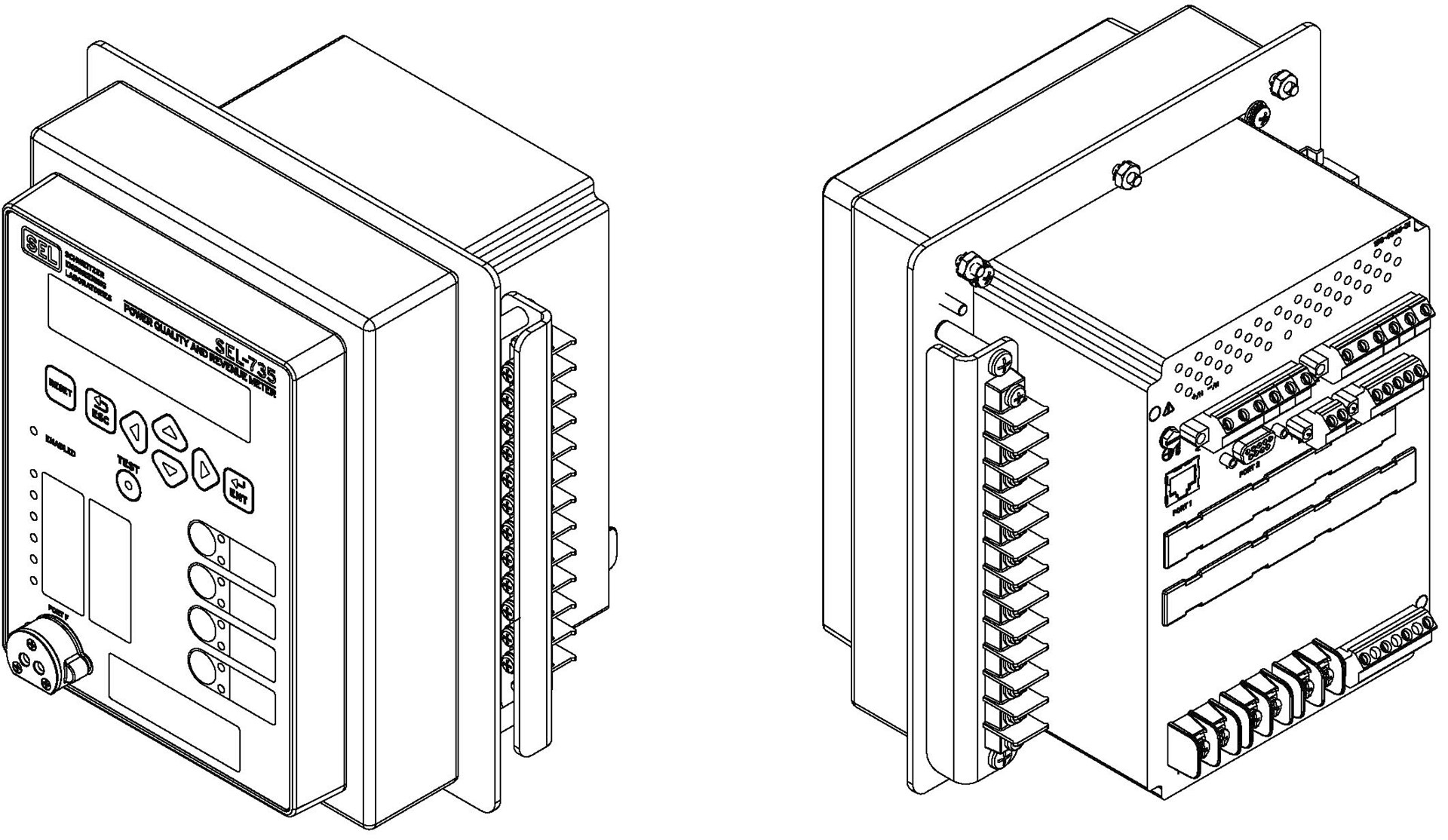

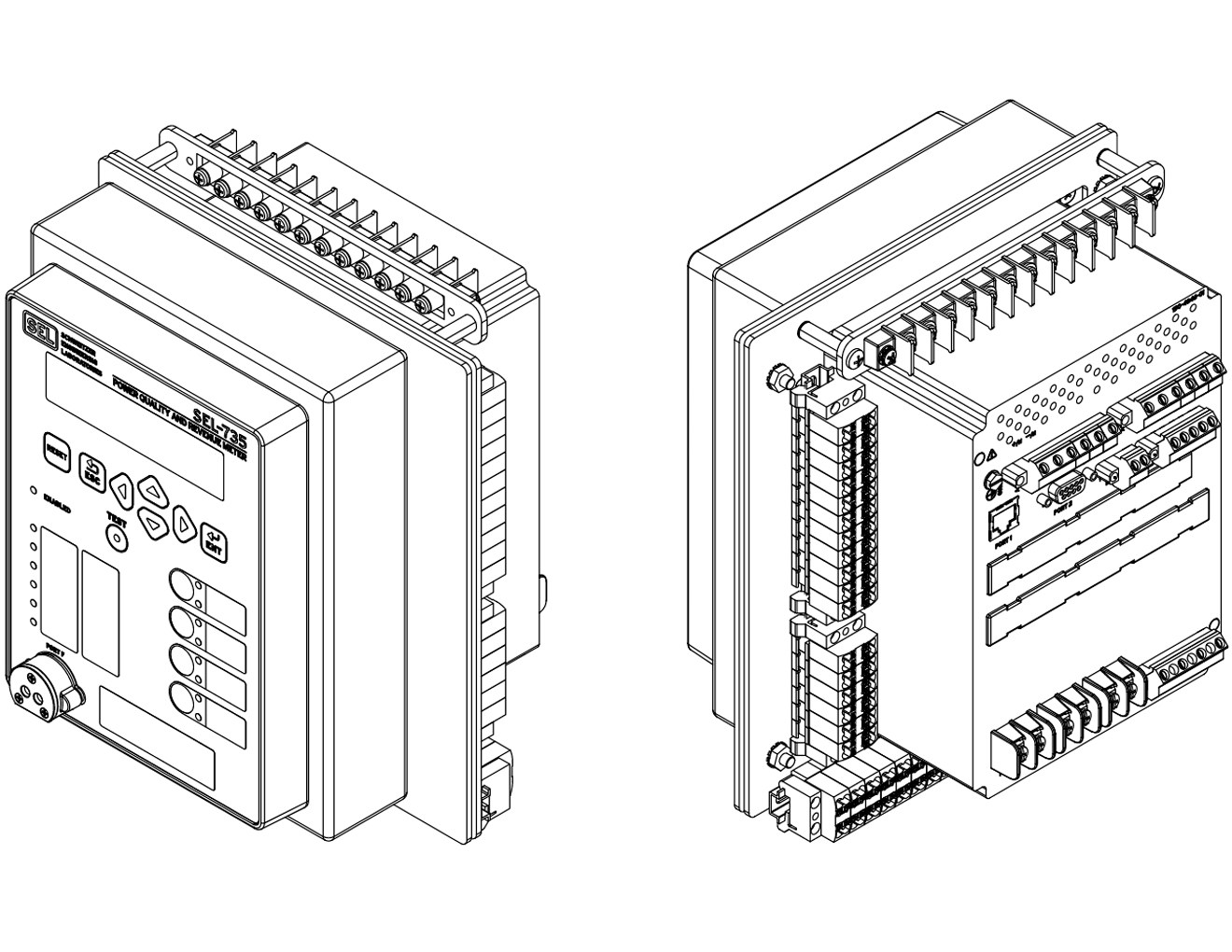

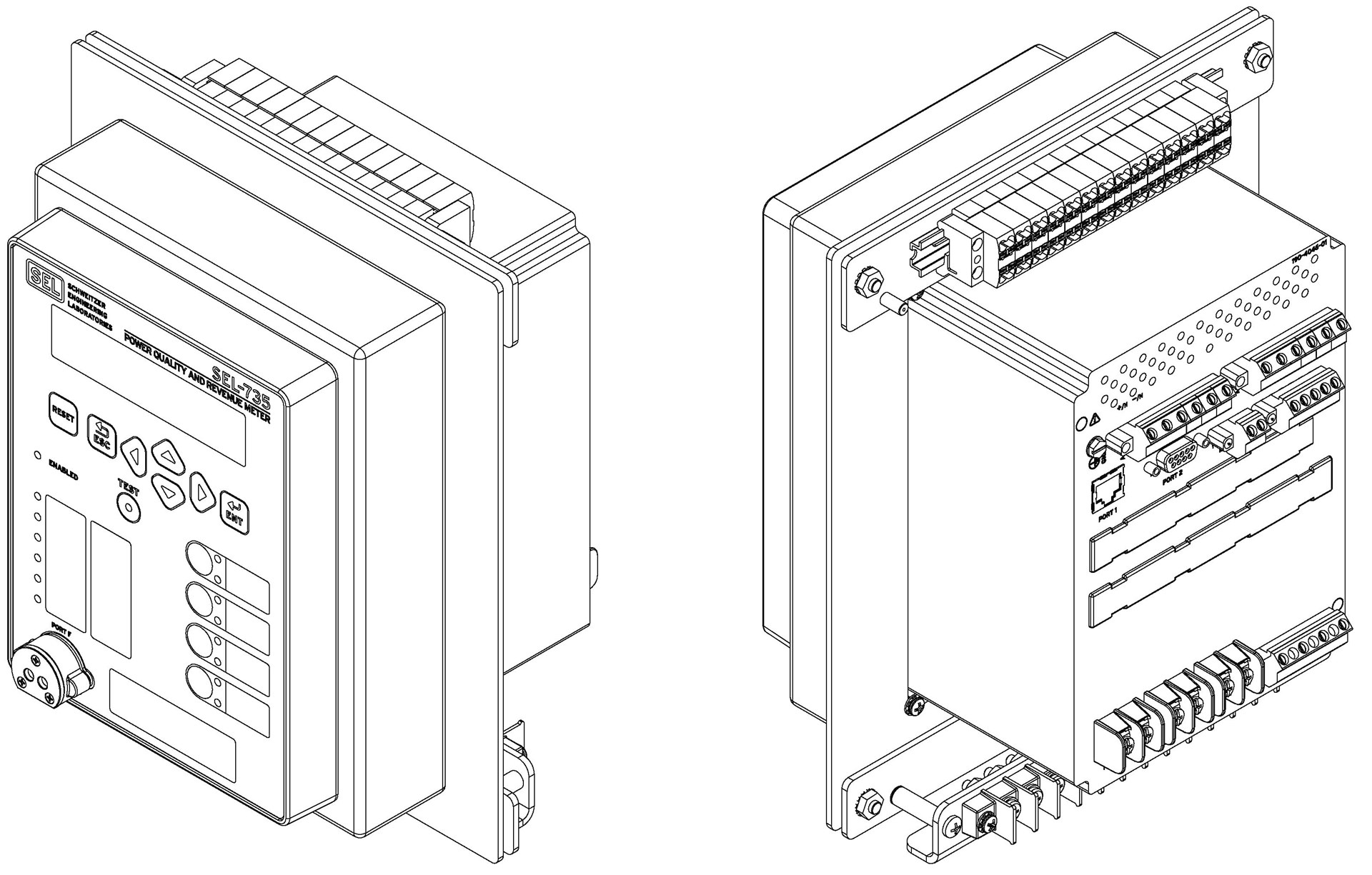

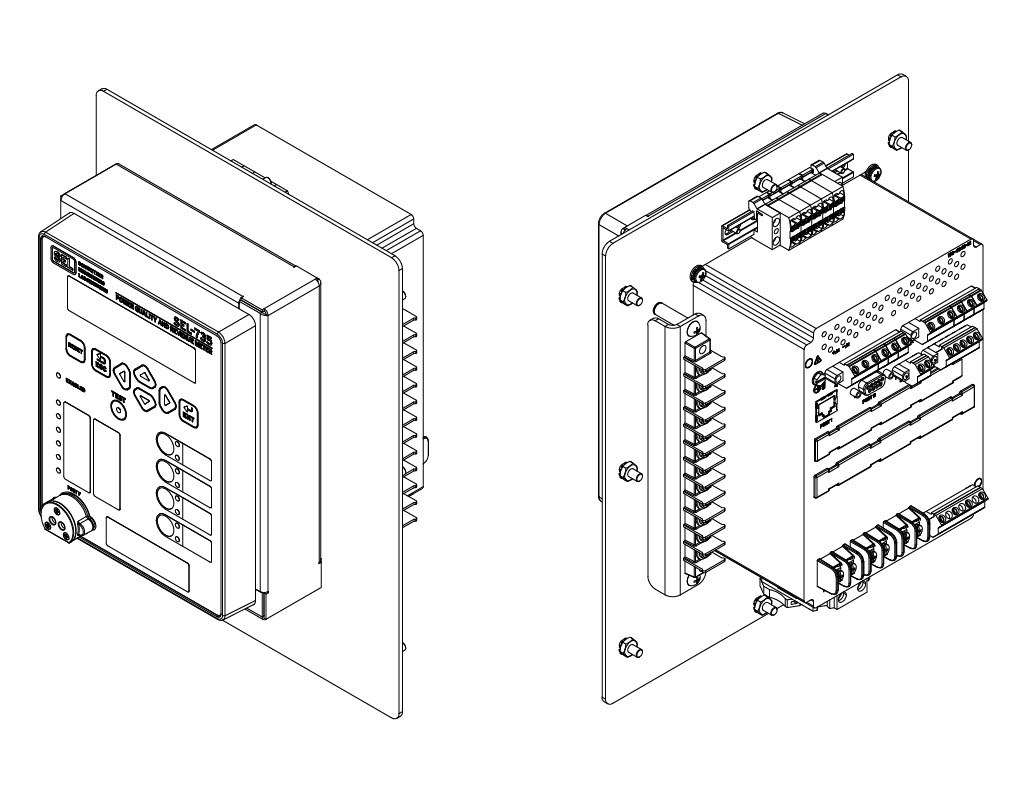

- 1

SEL-735 Power Quality and Revenue Meter

- 2

45–90 mm projection meter mount

- 3

Mounting plate

- 4

CT and PT terminal blocks

- 5

Supply terminal blocks

12345

-

-

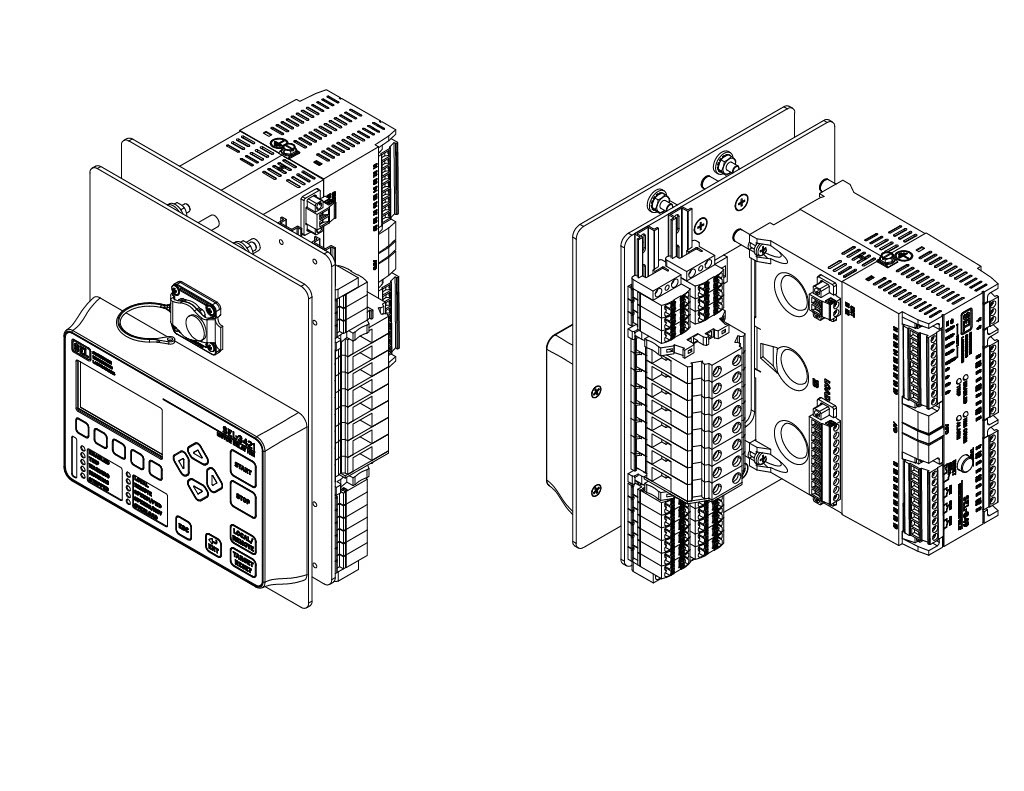

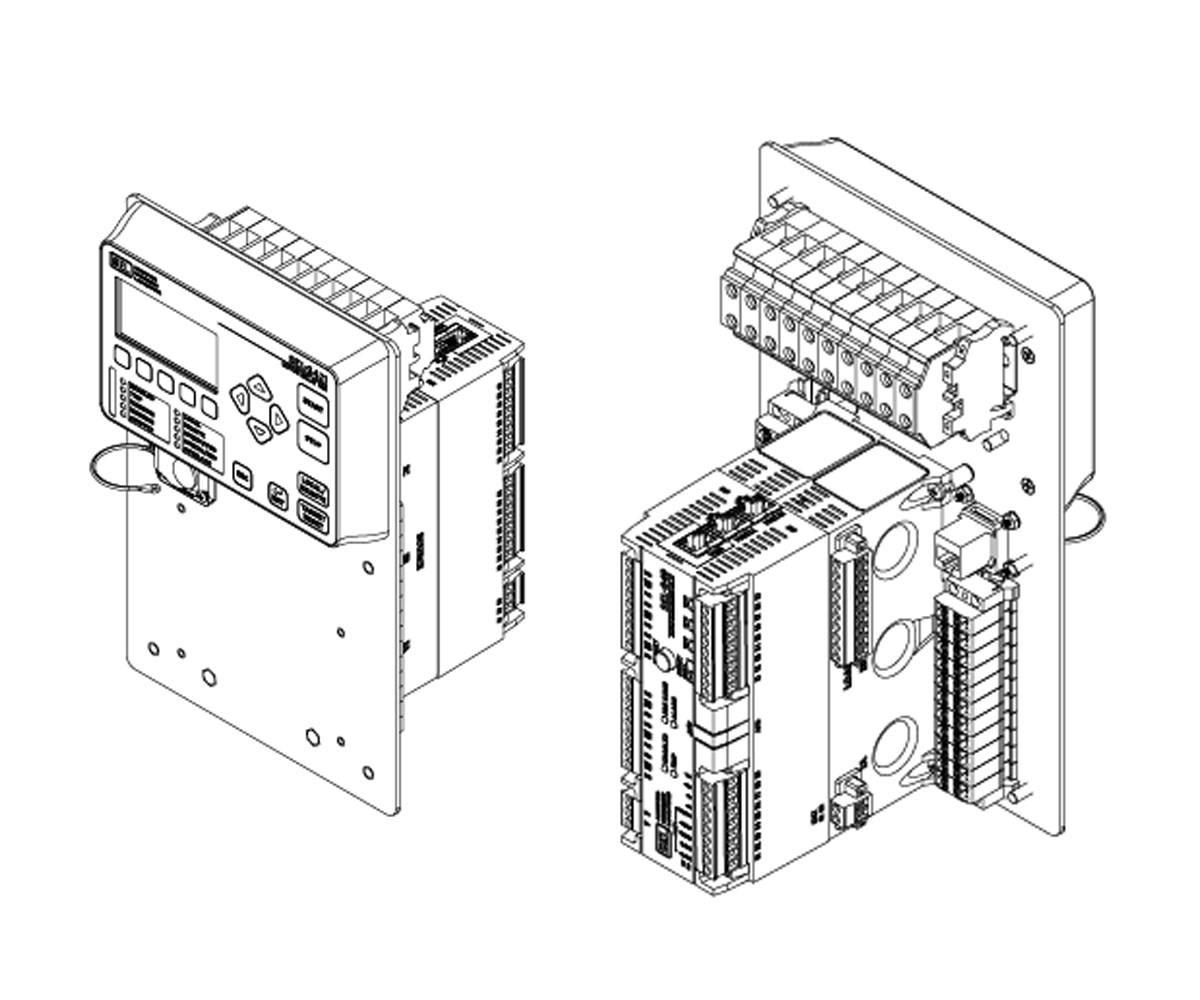

- 1

Local access port

- 2

Mounting plate

- 3

SEL-3421 Motor Relay HMI (With LCD)

- 4

CT and PT terminal blocks

- 5

Control terminal blocks

- 6

SEL-849 Motor Management Relay

123456

-

-

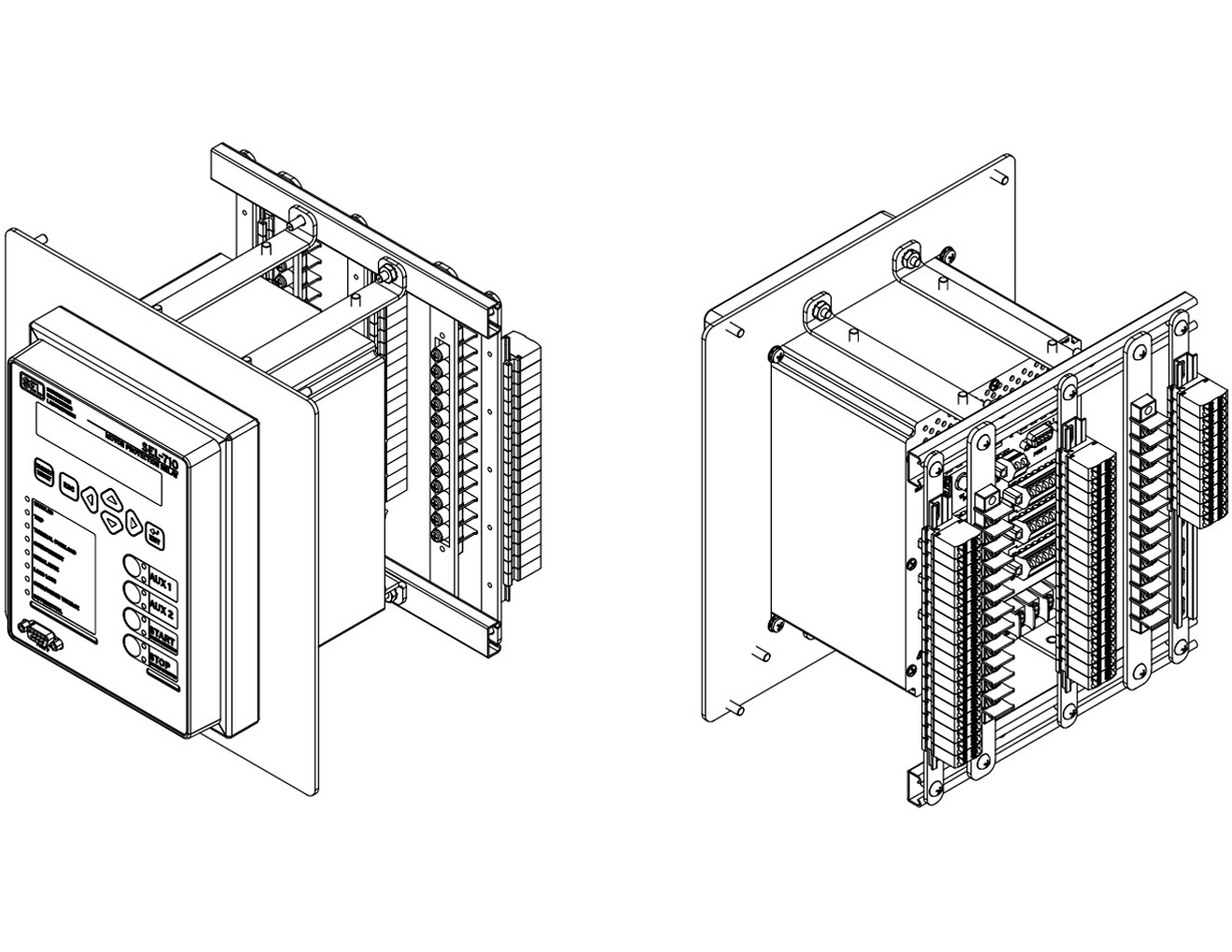

- 1

SEL-710 Motor Protection Relay

- 2

Front mounting plate

- 3

Control and RTD terminal blocks

- 4

Rear mounting plate

- 5

CT and PT terminal block

- 6

24 Vdc power supply

123456

-

-

- 1

Local access port

- 2

Mounting plate

- 3

SEL-3421 Motor Relay HMI (With LCD)

- 4

Control terminal blocks

- 5

SEL-849 Motor Management Relay

- 6

CT and PT terminal block

123456 -

-

- 1

SEL-751 Feeder Protection Relay

- 2

45–90 mm projection mount

- 3

Mounting plate

- 4

Preassembled frame

- 5

Control and RTD terminal blocks

- 6

CT and PT terminal blocks

123456

-

-

- 1

SEL-751 Feeder Protection Relay

- 2

45–90 mm projection mount

- 3

Mounting plate

- 4

Preassembled bracket

- 5

Control and RTD terminal blocks

- 6

CT and PT terminal blocks

123456

-

-

- 1

SEL-3421 Motor Relay HMI (With LCD)

- 2

Local access port

- 3

Mounting plate

- 4

SEL-849 Motor Management Relay

- 5

CT and PT terminal blocks

12345

-

-

- 1

SEL-710 Motor Protection Relay

- 2

Mounting plate

- 3

Preassembled frame

- 4

24 Vdc power supply

- 5

Control and RTD terminal blocks

- 6

CT and PT terminal blocks

123456

-

-

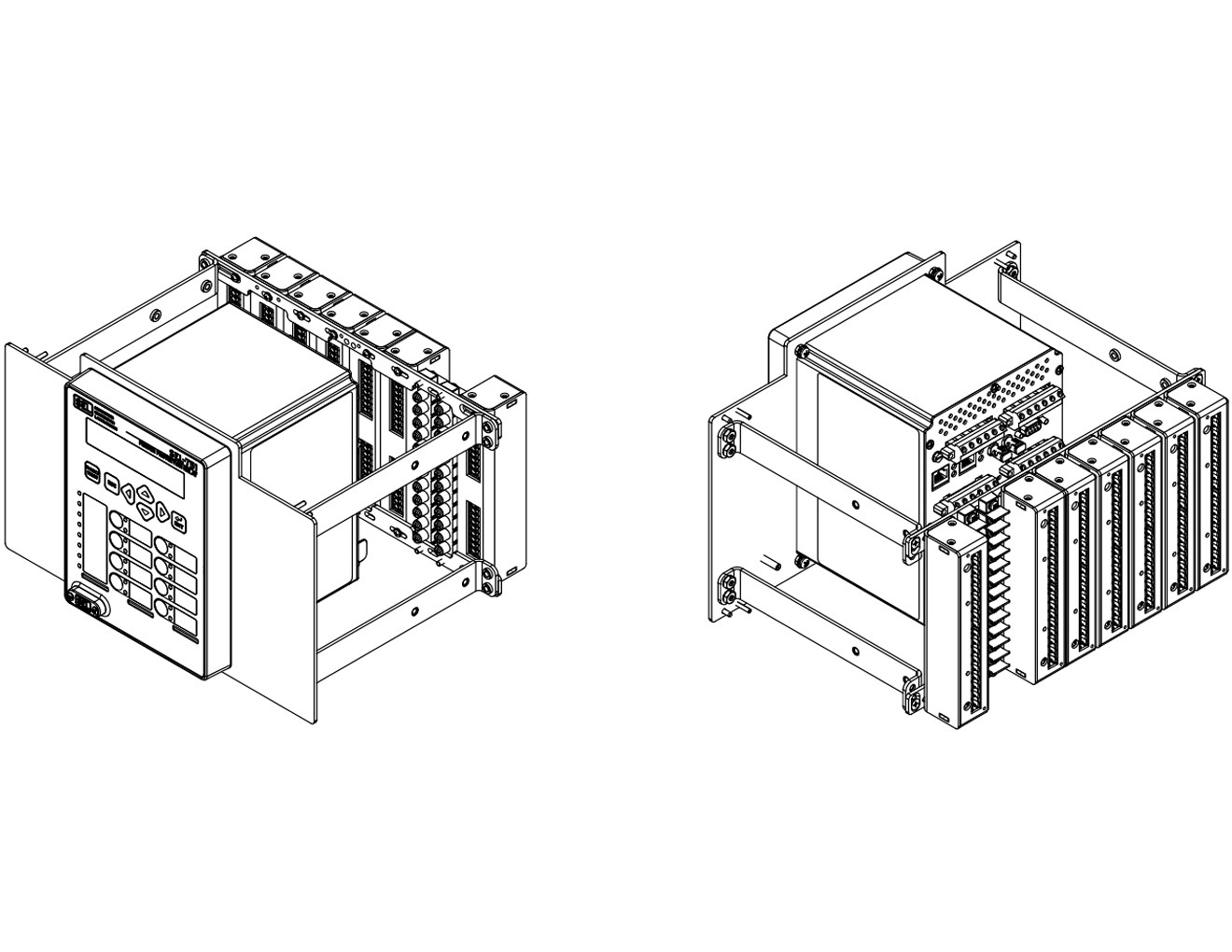

- 1

SEL-710 Motor Protection Relay (or SEL-751, SEL-787, or SEL-700G)

- 2

Mounting plate

- 3

Preassembled frame

- 4

Control and RTD terminal blocks

- 5

CT and PT terminal block

- 6

24 Vdc power supply

123456

-

-

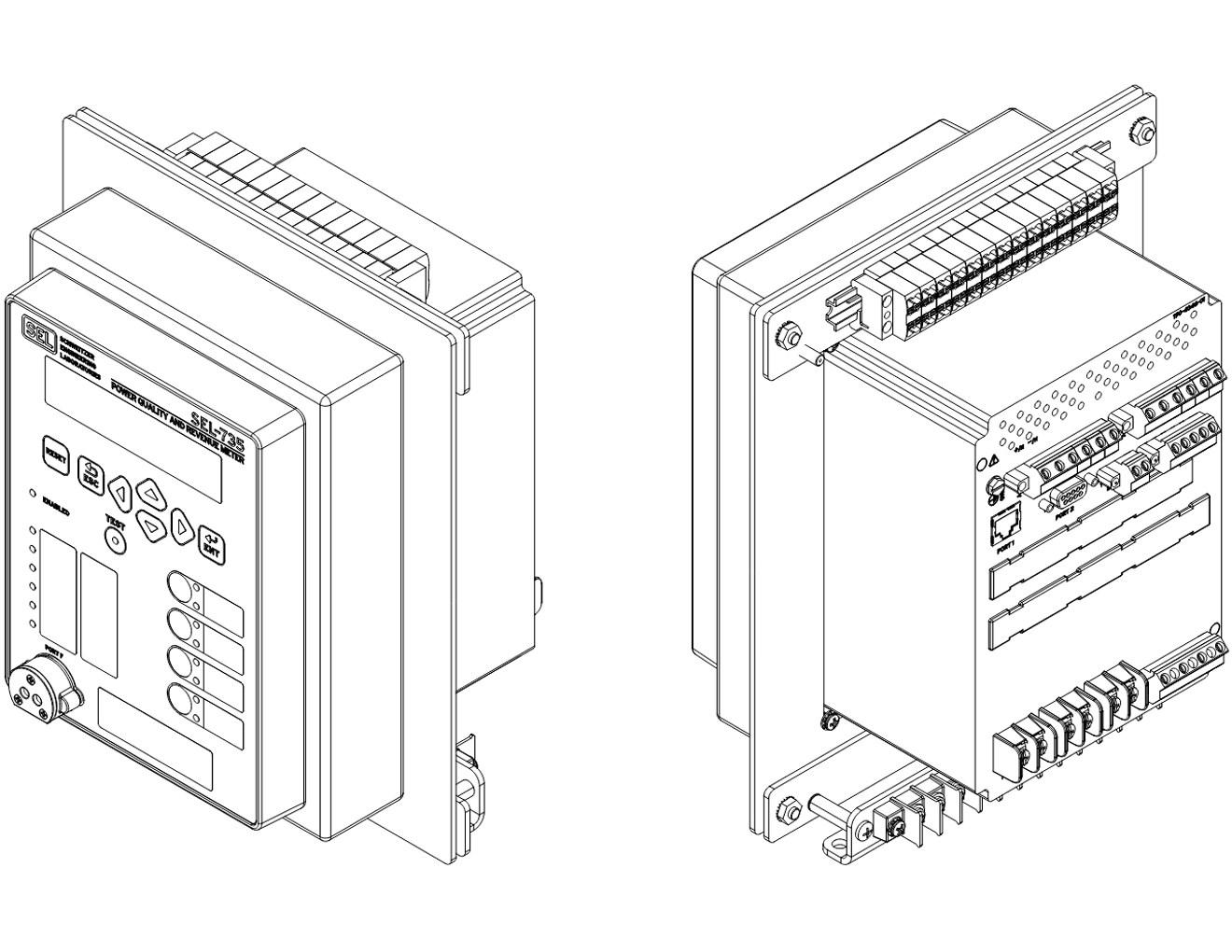

- 1

SEL-735 Power Quality and Revenue Meter

- 2

45–90 mm projection meter mount

- 3

Mounting plate

- 4

CT and PT terminal blocks

- 5

Terminal blocks

12345

-

-

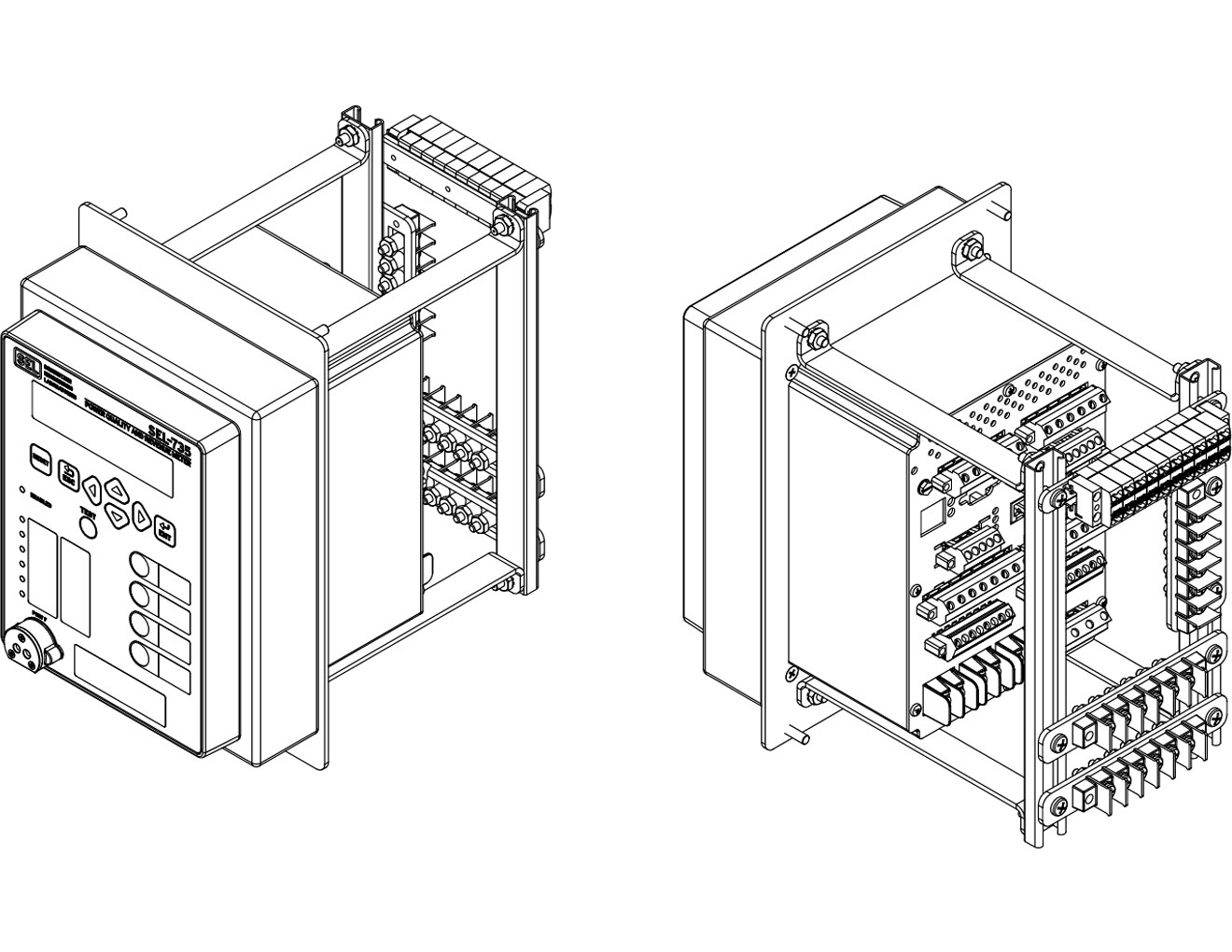

- 1

SEL-735 Power Quality and Revenue Meter

- 2

45–90 mm projection meter mount

- 3

Mounting plate

- 4

Preassembled frame

- 5

Terminal blocks

- 6

CT and PT terminal blocks

123456

-

-

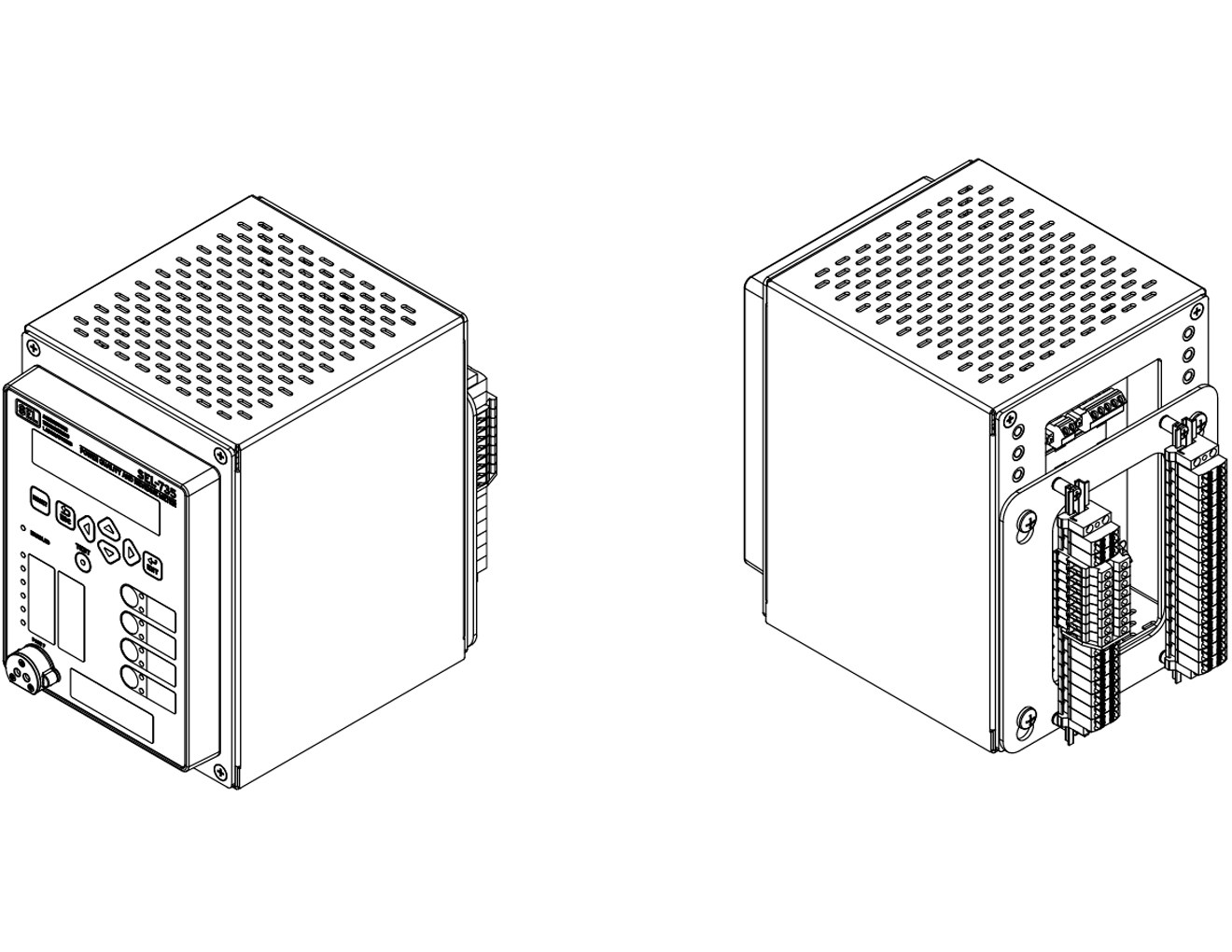

- 1

SEL-735 Power Quality and Revenue Meter

- 2

Preassembled enclosure

- 3

Communications terminal blocks

- 4

CT and PT terminal blocks

1234

-

-

- 1

SEL-751 Feeder Protection Relay

- 2

Mounting plate

- 3

Preassembled frame

- 4

MiCOM I/O terminal strip adapters

- 5

CT and PT terminal blocks

12345

-

-

- 1

SEL-787 Transformer Protection Relay

- 2

45–90 mm projection mount

- 3

Mounting plate

- 4

Preassembled frame

- 5

MiCOM I/O terminal strip adapters

- 6

CT and PT terminal blocks

123456

-

-

- 1

SEL-735 Power Quality and Revenue Meter

- 2

45–90 mm projection meter mount

- 3

Mounting plate

- 4

Terminal blocks

- 5

CT and PT terminal blocks

12345

-

-

- 1

SEL-751 Feeder Protection Relay

- 2

90 mm projection mount

- 3

Mounting plate

- 4

Preassembled frame

- 5

Control terminal blocks

- 6

CT and PT terminal blocks

123456

-

-

- 1

SEL-735 Power Quality and Revenue Meter

- 2

45–90 mm projection meter mount

- 3

Mounting plate

- 4

Terminal blocks

- 5

CT and PT terminal blocks

12345

-

-

- 1

90 mm projection mount

- 2

SEL-710 Motor Protection Relay

- 3

Mounting plate

- 4

Control terminal blocks

- 5

24 V power supply

- 6

CT and PT terminal blocks

123456

-

-

- 1

SEL-700 series relay

- 2

45–90 mm projection mount

- 3

Mounting plate

- 4

Preassembled frame

- 5

Control and RTD terminal blocks

- 6

CT and PT terminal blocks

123456

-

-

- 1

SEL-735 Power Quality and Revenue Meter

- 2

45–90 mm projection meter mount

- 3

Mounting plate

- 4

Communications terminal blocks

- 5

CT and PT terminal blocks

- 6

Supply terminal blocks

123456

-

-

- 1

SEL-3421 Motor Relay HMI (With LCD)

- 2

Local access port

- 3

Mounting plate

- 4

CT terminal block

- 5

SEL-849 Motor Management Relay

- 6

Control and PT terminal block

123456

-

Direct-Replacement Assembly Models

Digital Direct-Replacement Assembly Models

Details

The SEL Difference

SEL uses the same world-class manufacturing principles for our direct-replacement assemblies that we use for all our industry-leading products. This allows us to design, manufacture, and test high-quality and comprehensive solutions with reduced delivery times.

Quality

We build a prototype of each new design to create pre-engineered design drawings and document the installation procedure. This process ensures that the design meets functional specifications and enables the manufacturing facility to test and confirm the assembly prior to production.

The Firmware IDs for older versions of the firmware can typically be found in Appendix A of the instruction manual.

Sales Resource Central access is required to view the content in this tab.

Sales Resource CentralCommon Replacements

Replacement for GE Multilin 169, 269, and 369 Relays Without RTD

This assembly is equipped with the SEL-849 Motor Management Relay and the SEL-3421 Motor Relay HMI for motor applications without resistance temperature detectors (RTDs). The front of the mounting plate contains the SEL-3421 HMI and an Ethernet port for local access. The back of the plate contains the SEL-849 relay and the CT, PT, and control terminal blocks. All connections between the SEL relay and interposing terminal blocks are prewired.

Replacement for GE Multilin 169, 269, and 369 Relays With RTD

This assembly is equipped with the SEL-710 Motor Protection Relay for motor applications with up to ten RTDs. It consists of two components: a front mounting plate and a rear mounting plate. The front mounting plate contains the SEL-710 relay and the CT and PT terminal block. The rear mounting plate contains the control and RTD terminal blocks and a 24 Vdc power supply to provide wetting voltage. All connections between the SEL relay and interposing terminal blocks are prewired. For shallow compartment applications, two extension rings are available to projection-mount the SEL-710.

Replacement for GE Multilin SR469 Relays

This assembly is equipped with the SEL-710 Motor Protection Relay for motor applications with up to 12 RTDs. It consists of a mounting plate, frame, and terminal blocks, which all come preassembled as a single unit. The front of the mounting plate contains the SEL-710 relay. The back of the plate and the adjoining frame contain the CT, PT, control, and RTD terminal blocks and a 24 Vdc power supply to provide wetting voltage. All connections between the SEL relay and interposing terminal blocks are prewired.

Replacement for Westinghouse/CutlerHammer/Eaton IQ-1000, IQ-1000II, MP-3000, and MP-4000 Relays

This assembly is equipped with the SEL-849 Motor Management Relay and the SEL-3421 Motor Relay HMI for motor applications without RTDs. The front of the mounting plate contains the SEL-3421 HMI and an Ethernet port for local access. The back of the plate contains the SEL-849 relay and the CT, PT, and control terminal blocks. All connections between the SEL relay and interposing terminal blocks are prewired.